How to Select Flexible Cables for Industrial Applications

I recently went to a robotics exhibit at a local maker space. The ingenuity and diversity of the equipment on display was stunning. I was particularly impressed with Spot, the dog-like Boston Dynamics robot, though I must admit that I found its not-quite-canine movements unnerving.

This experience brought to mind the challenges of distributing power and data in moving machinery. For well-established applications like pick-and-place systems to emerging fields like cobots, cables need to bend and twist regularly. This is a problem for run-of-the-mill cabling designed for static applications. When subjected to repeated flexing, these cables can degrade due to a variety of factors. For example:

- The cable jacket can be damaged by abrasion with cable management systems or other environmental elements.

- The insulation and jacketing materials can crack or break from the repeated strain.

- The conductors and shielding can fracture, especially in applications with complex motions, requiring continuous cable flexing.

In rugged environments, the effects of this degradation can be exacerbated by the presence of abrasive or corrosive materials and extreme temperatures. These environmental hazards can weaken the jacket and insulation, making them vulnerable to failure.

It’s helpful to take an outside-in design philosophy to ensure longevity in applications like these. For example:

- Start by ensuring that the cable jacket can withstand exterior environmental hazards.

- Determine if a shielding system is required and confirm that it can withstand the expected strain.

- Ensure the cable has a suitable interior structure, including conductors designed for repeated flexing.

We will examine each of these factors in closer detail.

Choosing a durable cable jacketing material

Flexible cables for industrial environments typically feature jackets composed of polyvinyl chloride (PVC), polyurethane (PUR), or thermoplastic elastomer (TPE). While each material has its advantages, TPE offers superior resistance to most environmental hazards (Figure 1). TPE also stands out for its exceptional flexibility, enduring repeated bending and flexing without cracking or breaking.

Figure 1 : TPE offers superior resistance to most environmental hazards. (Image source: Alpha Wire)

Figure 1 : TPE offers superior resistance to most environmental hazards. (Image source: Alpha Wire)

These advantages can be seen in the Xtra-Guard Flex TPE Cables from Alpha Wire. Rated for 1 million flex cycles and boasting Oil Res I/II and FT4 flame ratings, these cables are designed to provide high reliability and performance in applications such as manufacturing robotics and motion control.

These cables are available in power-limited tray cable (PLTC) or tray cable (TC) variants. The PLTC and TC ratings mean that a cable can be run directly in cable trays or raceways without any additional protection, even in outdoor environments, simplifying installation and lowering costs.

Alpha Wire also offers Xtra-Guard Continuous Flex TPE Control Cables for rolling-flex applications, such as gantry systems. These cables feature even more robust construction to withstand extreme stress.

Balancing flexibility and effectiveness in shielding material

The options in electromagnetic interference (EMI) shielding can be overwhelming. Engineers must choose from a broad array of materials, such as copper and aluminum, as well as numerous construction methods, such as foils and braids. Each option has tradeoffs concerning shielding effectiveness, mechanical resilience, cost, and weight.

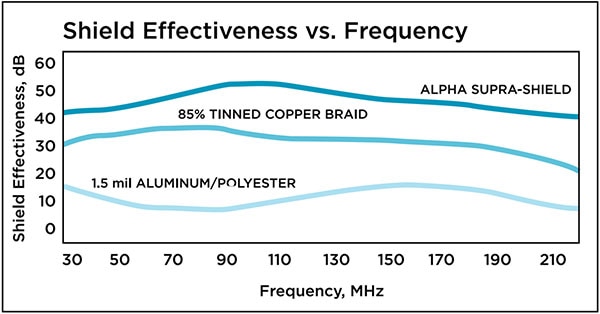

One way to minimize these tradeoffs is to use a combination of shields. For example, Alpha Wire’s exclusive Supra-Shield uses an aluminum/polyester/aluminum foil and a tinned copper braid shield for a tight 75% coverage. As illustrated in Figure 2, the combination of foil and braid shields provides outstanding EMI performance while retaining excellent flexibility.

Figure 2: Supra-Shield combines foil and braided shields to achieve superior performance. (Image source: Alpha Wire)

Figure 2: Supra-Shield combines foil and braided shields to achieve superior performance. (Image source: Alpha Wire)

Designing conductors for durability

The conductors in a flexible cable should use a stranded design to ensure longevity (Figure 3). This design distributes the stress from flexing rather than concentrating it on a single point, reducing metal fatigue and the risk of breakage. All Xtra-Guard Flex TPE Cables use a stranded design, offering sizes ranging from 10 to 20 AWG and conductor counts from 2 to 12.

Figure 3: Stranded conductors like those shown here distribute strain to reduce metal fatigue. (Image source: Alpha Wire)

Figure 3: Stranded conductors like those shown here distribute strain to reduce metal fatigue. (Image source: Alpha Wire)

Conclusion

Moving machinery presents unique challenges when it comes to cabling. Ensuring that cables can withstand the rigors of these applications and their operating environment is crucial for the longevity and reliability of the system. As shown, materials like TPE offer superior resistance and flexibility, while innovative shielding systems like Alpha Wire's Supra-Shield provide optimal EMI performance without sacrificing durability. Furthermore, the use of stranded conductors in cables ensures that they can endure the stresses of their applications.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum