Four Resolutions to Supply Chain Success in 2024

It’s been a rough start to the year. Headlines chronicle a shifting political landscape, numerous conflicts, and an array of potential and realized natural disasters. It’s easy to predict that the coming year will likely be challenging and dynamic regarding semiconductor supply shifts and trends. At the same time, technological advances in artificial intelligence (AI), the Industrial Internet of Things (IIoT), and other smart technologies offer ways of staying ahead of the curve.

Plenty of growth

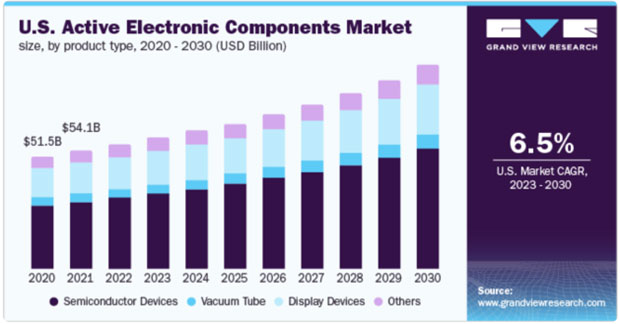

Like many, I expect electronic components will continue to enjoy strong growth for the foreseeable future. The global electronic components market was valued at $186.38 billion in 2022.1 It is projected to climb to $328.5 billion by 2031, a growth rate of 6.5% annually.

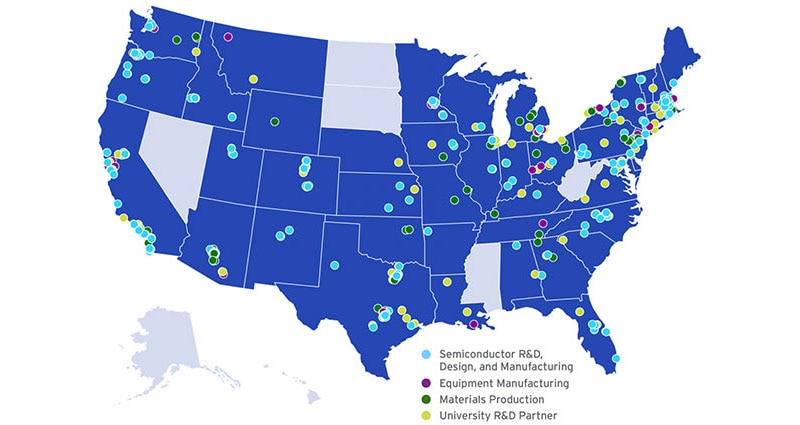

A similar growth rate is expected in the United States (US), driven by the increasing demand for active electronic components and the widespread usage of connected devices (Figure 1). This expectation aligns with the US investment in building semiconductor fabs.

Figure 1 : The demand for active electronic components across numerous sectors and the widespread usage of connected devices are some elements driving electronics growth. Semiconductors account for the lion’s share of revenue. (Image source: Grandview Research)

Figure 1 : The demand for active electronic components across numerous sectors and the widespread usage of connected devices are some elements driving electronics growth. Semiconductors account for the lion’s share of revenue. (Image source: Grandview Research)

These growth expectations alone are a reason for optimism. Most electronic sectors are outpacing almost any global economy by a comfortable margin. Everyone involved must keep pace with the industry and market changes to capture that growth.

War and electronics

This may be the year that geopolitics matters more than in the past. Tensions are running high with unrest across the globe. Further, trading concerns between the US and China are likely to continue. It’s easy to say we should cut back on trade with China, but we will likely remain tightly coupled for mutual benefits. Even products produced elsewhere, such as Mexico or Malaysia, will probably still tap China for rare earth minerals or chips. Also, as more countries delve into semiconductor fabrication, there will be new partnership opportunities to explore.

It's an excellent time to consider some supply chain resolutions for the New Year.

#1: Stay in touch with your supply chain at a deeper level. It’s important to know who you are partnering with and who they, in turn, are partnering with. If US/China relationships cool, it’s important to understand where the supply chain may be impacted.

New vectors of supply chain attack

Risk is up in a variety of supply chain areas. Climate change, increased Environmental, Social, and Governance (ESG) pressure, and more cybersecurity hazards will all change how organizations must measure and manage risk. Compared to two years ago, climate events have increased eight-fold, according to Resilinc.2 Forest fires are up 26%, and tornadoes have increased by 108% in 2023 compared to the year before. It’s challenging to find a region safe from some sort of climate event.

On the ESG and compliance front, Resilinc tracked a 79% increase in FDA/EMA/OSHA action alerts. This may be due to the increasing enforcement and new legislation associated with ESG. The German Due Diligence Act and the Corporate Sustainability Due Diligence Act in Europe were both adopted in the last year or so.

Meanwhile, cyberattacks were up 36%. While malicious attacks from bad actors have been a problem for years, the increasing connectivity of the supply chain with outside partners and organizations can open new vulnerabilities. Innovative OEMs will want to monitor their security practices and audit their key vendors to ensure their partners do what’s necessary to avoid being compromised. All these shifts have the potential to impact the supply chain.

#2: Expand the definition of risk. Think beyond the traditional risk factors and look at those emerging in new and different ways.

Inventory overhang

The component shortages that have plagued the market for the past few years are largely behind us. However, OEMs and distributors may hold more product than necessary as the pendulum swings the other way. Rising interest rates are also changing the math for buying up inventory to mitigate risk. These shifting realities may cause a blip that looks like a shortage but will be less disruptive.

#3: Stay tuned to inventory shifts and business realities. Staying alert for surprise short-term shortages is essential as we return to normal lead times and availability.

The digital supply chain

Amidst the various shifts in the supply chain, advanced technologies will be a significant motivator for positive change. Through 2024, half of supply chain organizations will invest in applications that support AI and advanced analytics capabilities, according to KPMG.3 The list of technologies being applied to the sector is long: generative AI, data analytics, automation, machine learning, IoT, and blockchain. Combined with clean sources of good data, technology can make a powerful difference to organizations trying to streamline operations, reduce risk, and increase the transparency and efficiency of the supply chain.

#4: Continue to evaluate how emerging technologies can enhance supply chain performance. The biggest challenges of 2024 are likely to be linked with increasing risk and lack of visibility. Strategic investment in technology can address these concerns and lead to a year of success.

The Year of the Dragon brings many challenges as tensions rise and global alignments shift. Nonetheless, semiconductor growth is in the cards. By making and adhering to a few New Year’s resolutions, you can maintain your supply chain resilience to weather the storms.

References

1: https://straitsresearch.com/report/electronic-components-market

3: https://kpmg.com/xx/en/home/insights/2023/12/supply-chain-trends-2024.html

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum