Design Ideas for Software-Configurable Analog I/O

There was a time when analog I/O was some of the most specialized, fixed-function hardware around. For example, a current driver and a voltage sensor were entirely different parts, and trying to reverse their roles would have been absurd.

Software-configurable analog I/O has turned that absurdity into a practical reality. Today, a single analog integrated circuit (IC) can fill many roles. For example, the MAX22000 industrial I/O device from Analog Devices offers six analog inputs and one analog output, all configurable for either voltage or current mode.

The flexibility of these ICs makes them ideal for multi-function systems, as the hardware can be reconfigured on the fly to handle various input and output types. Even better, configurable I/O can often be fine-tuned through software, enhancing accuracy and precision.

Case study: portable multi-function calibrator

To illustrate these benefits, consider the requirements of calibration systems. Many industrial analog I/O modules require periodic calibration to ensure proper operation. Typically, this calibration involves a collection of instruments that can be cumbersome to transport and operate. By replacing these instruments with a multi-function device, technicians can be more productive while improving the precision of their work.

For example, the calibrator design shown in Figure 1 can be used to create a portable multi-function system that can replace multiple instruments. Moreover, this battery-powered design can achieve performance comparable to bulky desktop calibrators.

Figure 1 : A portable multi-function calibrator can be built around the MAX22000 I/O device. (Image source: Analog Devices)

Figure 1 : A portable multi-function calibrator can be built around the MAX22000 I/O device. (Image source: Analog Devices)

The heart of the design is the MAX22000. In addition to supporting both voltage and current sensing, its inputs can be configured for thermocouple mode or resistance temperature detector (RTD) mode. This makes the chip ideal for calibrating temperature transmitters or signal conditioners, as it can compare their voltage or current outputs against the temperature readings from a thermocouple or RTD.

A noteworthy feature of this design is its incorporation of temperature compensation. Specifically, it includes two instances of the MAX31875, a tiny 0.84 × 0.84 × 0.35 millimeter (mm) temperature sensor. As shown in Figure 1, one of these ICs can be placed adjacent to the MAX22000, with the other near the source terminals, enabling temperature compensation of the voltage gradient between the terminals.

Designing an embedded system around software-configurable analog I/O

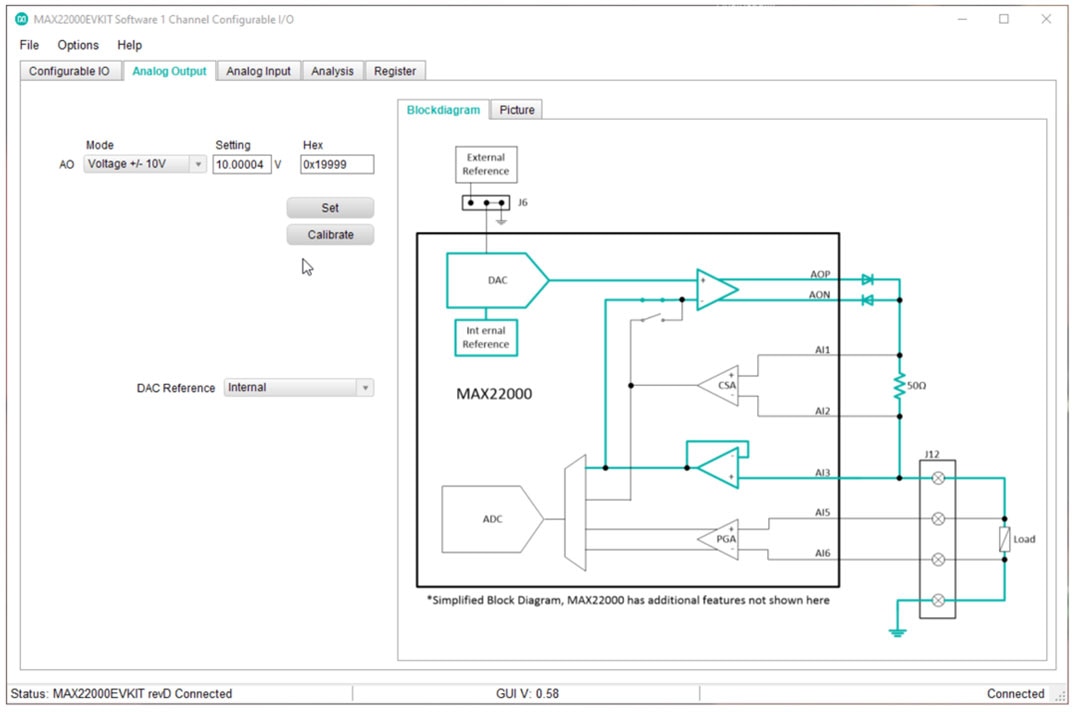

If you’re considering basing a system like this on the MAX22000, several design considerations are worth noting. I recommend first experimenting with the MAX22000EVKIT# evaluation kit (Figure 2) to shorten the IC configuration learning curve.

Figure 2 : The MAX22000EVKIT# evaluation kit includes software to configure the MAX22000 I/O device. (Image source: Analog Devices)

Figure 2 : The MAX22000EVKIT# evaluation kit includes software to configure the MAX22000 I/O device. (Image source: Analog Devices)

You’ll need a more robust means of configuring the device for a production-ready design. The portable calibrator design shows one way this can be done. The MAX22000 connects to the MAX32625, an Arm Cortex-M4F microcontroller, via a Serial Peripheral Interface (SPI). The microcontroller connects to an onboard FTDI FT234XD-R USB bridge through its universal asynchronous receiver/transmitter (UART) port.

Many designs will also require a display and user controls. In the case of a portable calibrator, a small, low-resolution touchscreen like the Nextion NX4827T043 - GE from Seeed Technology Co., Ltd. serves both purposes effectively. This 4.3 inch (in.) (109.22 mm) resistive display offers a 480 x 272 resolution, which is more than enough for a basic user interface.

If you’re new to embedded systems, I recommend starting with an evaluation board like the MAX32625MBED. Based on the MAX32625 microcontroller, it provides a complete system for developing and debugging applications. It also provides a handy means of connecting I/O peripherals like USB ports and displays through Arduino-compatible connectors.

Power management for battery-powered systems

You’ll need to incorporate voltage conversion and battery monitoring for battery-powered systems like the portable calibrator. In the example design, voltage conversion is handled by the MAX17498, a flyback converter that boosts the 5 volt USB input to the 7.2 volts required by the battery pack. Meanwhile, a MAX17320X20-T fuel gauge manages battery states, including voltage, current, and temperature.

As with the other components discussed in this blog, these ICs have evaluation kits. Specifically, you can try out the flyback convertor with the MAX17498BEVKIT and test the fuel gauge with the MAX17320X2EVKIT. You can also use the MAX31875EVKIT to try out the tiny MAX31875 temperature sensor.

Conclusion

In the rapidly evolving landscape of industrial electronics, the development of software-configurable analog I/O devices allows for unprecedented versatility and efficiency in system design and operation. The MAX22000 from Analog Devices is a good example, offering a multifaceted approach to analog signal processing that can be reconfigured on demand to suit various applications.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum