Industrial Sensing Solutions Made Easy

(Image source: Molex)

(Image source: Molex)

You need a sensor assembly for your industrial automation design, and you need it quickly. But the assembly involves multiple components, and there are a number of sensors to choose from. Where to begin?

In the meantime, the clock is ticking. And your customers are waiting.

That’s why Molex works closely with DigiKey to provide you with a complete sensing solution from one convenient location.

Molex Distribution Block + Molex Cable + Contrinex Sensor = A Complete Sensing Solution

DigiKey offers Molex distribution blocks and cables along with Contrinex sensors in an online format that makes it easy for you to find all the components you require for a complete sensing solution from one user-friendly website. This will eliminate the need for additional vendors and ensures the entire sensor assembly comes in one reliable shipment.

Types of Sensors

Through DigiKey, Molex offers a range of sensor options so your sensor solution will be exactly the right one for your specific application.

But what kind of sensor do you need? Inductive? Photoelectric? And if you need photoelectric, what kind – reflective, diffuse or through-beam? Choosing the right sensor can be tricky.

To help with your decision process, the table below shows, at one glance, some of the differences between inductive and photoelectric sensing capabilities.

| Inductive Sensor Capabilities | Photoelectric Sensor Capabilities | |

|---|---|---|

| Capability | Uses magnetic field to detect metal objects | Uses light to detect objects made from a range of materials |

| Sensing Range | 0 to 40.00 mm | 0 to 50 m |

| Operating Temperatures | -40 to +85˚C | -25 to +55˚C |

Furthermore, the diagrams and tables below spell out the differences between Contrinex through-beam, reflective and diffuse photoelectric sensors.

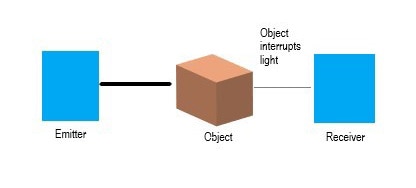

Through-Beam Photoelectric Sensors:

| Pros | Cons |

|---|---|

| Long sensing range | Installation of two devices is necessary, the emitter and the receiver |

| Detects objects regardless of their color, reflective properties or surface | More costly due to the need for two devices |

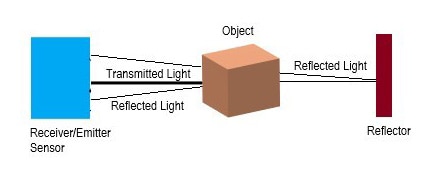

Reflective Photoelectric Sensors:

| Pros | Cons |

|---|---|

| Saves space because emitter and receiver are in the same device | Reflective objects might lead to erroneous activation |

| Single device results in faster installation process | Lower sensing distance as compared to through-beam sensors |

| Cost-effective due to needing only one device |

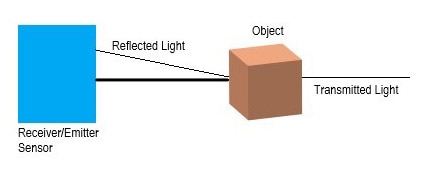

Diffuse Photoelectric Sensors (object reflects light):

| Pros | Cons |

|---|---|

| Saves space because emitter and receiver are in the same device | Provides the shortest sensing distance of the three types of sensors |

| Single device results in faster installation process | |

| Cost-effective due to needing only one device |

Accommodating Specialized Sensing Requirements

Transparent objects present challenges for accurate sensing. Contrinex photoelectric sensors use patented UV technology that enables them to detect transparent objects, such as bottles, with superior accuracy. Additionally, these photoelectric sensors have color sensing and control capabilities to aid automated sorting by color.

Other Sensor Considerations

With an integrated IO-Link interface and ASICs embedded in every device, Contrinex sensors deliver a reliable and easy-to-install system. Furthermore, whether you need basic sensing capabilities or a system to withstand extreme conditions, both Contrinex inductive and photoelectric sensors offer a range of features appropriate for your design’s specific application:

- Metal or plastic housings

- Cylindrical or cubic photoelectric sensors

- Subminiature photoelectric sensors

- Miniature inductive sensors

No matter what challenges your application presents, explore DigiKey’s Molex sensor system portfolio and find your complete sensing solution today!

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum