Artificial Intelligence Promises Supply Chain Improvements

The global electronics supply chain is increasingly characterized by its unpredictability. Shocks to the system are becoming more frequent and severe, and organizations are focusing on decreasing their exposure by increasing their supply chain resilience. Artificial intelligence (AI) technologies can play a significant role.

Finding supply chain safety

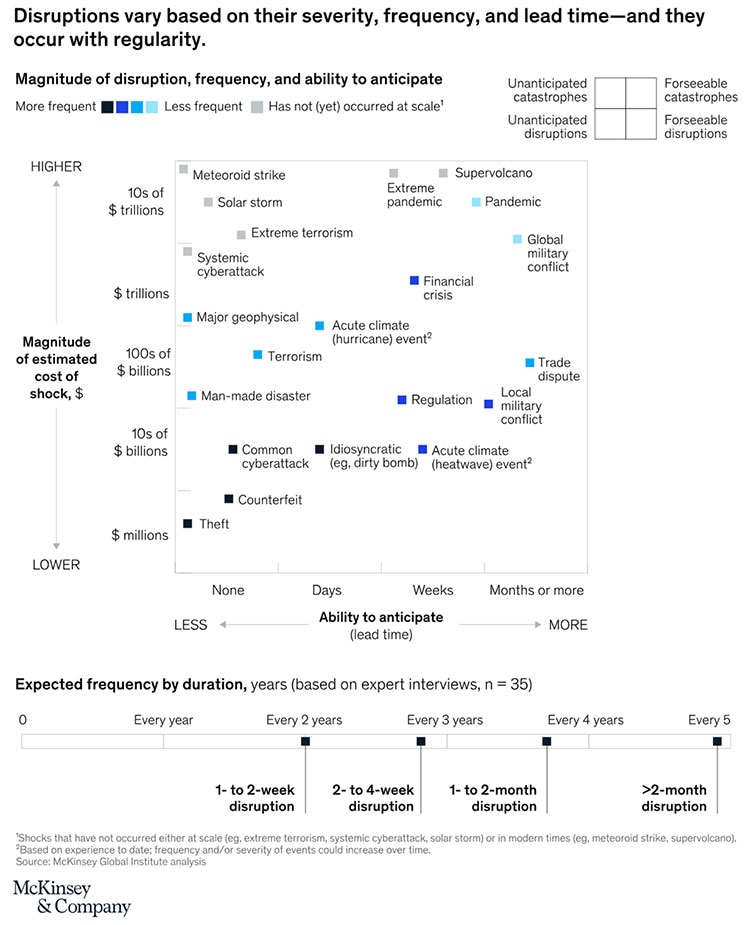

Many threats can cause supply chain disruptions (Figure 1). While some can be anticipated, others are much harder to predict, and all can result in substantial costs, ranging from millions to billions of dollars. These threats range from man-made challenges, such as shifting regulations, military conflicts, or cyberattacks, to natural events like pandemics and earthquakes.

Figure 1 : The factors that can disrupt the supply chain are numerous, varied, and inevitable. (Image source: McKinsey & Company)

Figure 1 : The factors that can disrupt the supply chain are numerous, varied, and inevitable. (Image source: McKinsey & Company)

Organizations must ask not whether a disruption will occur, but rather what type of disruption is most likely. Understanding how long a potential disruption can impact the supply chain is also essential.

These realities have forced industries to invest in technologies that raise transparency and resilience in the supply chain as much as possible. When a supply chain crisis hits, the organizations that can move most quickly to find alternate sources will win.

Technology chops

Supply chain applications and services that leverage AI have the potential to help. The list of use cases within the supply chain is long and includes:1

- Production planning: AI can optimize production schedules to improve delivery, prioritize products across the portfolio, reduce production and distribution costs, and reduce the cost of last-minute changes.

- Predictive forecasting: AI can help us better understand procurement needs over time by considering historical data, customer behavior, market trends, and various external factors.

- Inventory planning and management: Traditional material requirement planning (MRP) systems lack responsiveness. By modeling real-world supply and demand uncertainties, it’s possible to reduce the need to hold high inventory levels to buffer against the unexpected.

- Sourcing: AI can create a unified supplier view to help organizations spot price changes, shifts in supplier risk profiles, and cost savings opportunities.

- Supply network design: Modeling capabilities allow organizations to revisit existing supply networks regularly, translating into agility, cost advantage, risk mitigation, and customer responsiveness.

- Logistics management: AI can help organizations spot emerging transportation and logistics issues, allowing them to react promptly and proactively.

AI has a good story to tell when it comes to proactively identifying and reacting to disruptions.2 For example, AI can scrape websites across the internet for data on potential new suppliers. Consider what digging can identify: reports on suppliers’ finances, customer ratings, sustainability scorecards, diversity scores, intellectual property information such as patents and design awards, and documents from U.S. Customs. Social media and newsfeeds can yield business information such as human resource changes and organizational restructuring.

AI also has the potential to help manufacturers optimize the management of existing suppliers. By delving into supplier information held within the organization, for example, some AI tools can identify supply options for upcoming needs within the current roster of business partners. These tools use previous purchase orders, invoices, quotes, and other historical procurement data to identify potential sourcing matches within the existing list of partners. This can reduce the need to onboard new suppliers, which can be time-consuming and expensive.

Measurable worth

Corporate leaders are optimistic about AI's potential impact. According to a recent survey, seven out of ten CEOs say AI delivers a strong return on investment for their organization.3 Supply chain (identified by 76%) and procurement (identified by 71%) are the two areas where AI is deployed most. Other business activities include quality control (47%) and automation (37%).

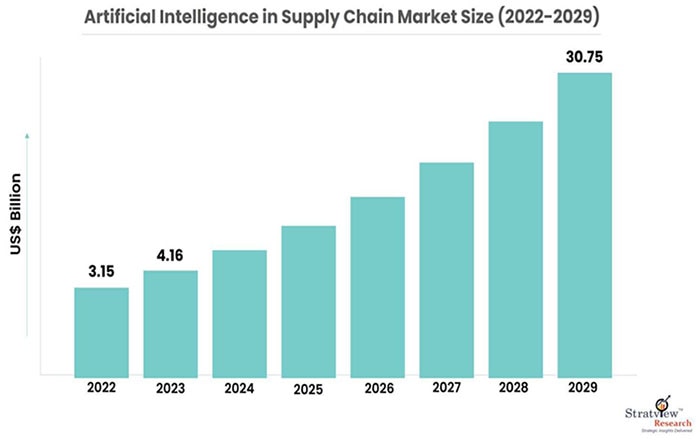

Market researchers echo the rosy prediction for AI in the supply chain. According to Stratview Research (Figure 2), the market is expected to grow from $3.15 billion in 2022 to $30.75 billion by 2029.4 This equates to an annual growth rate of 38.5%.

Figure 2 : The market for AI in the supply chain is expected to grow from $3.15 billion in 2022 to $30.75 billion by 2029. (Image source: Stratview Research)

Figure 2 : The market for AI in the supply chain is expected to grow from $3.15 billion in 2022 to $30.75 billion by 2029. (Image source: Stratview Research)

The increasing volume of data and a greater focus on the need for supply chain visibility and transparency, combined with the growing adoption of AI, are driving growth in the market. A lack of AI expertise in the workforce may be one stumbling block.

AI is poised as at least one answer to the increasing complexity of the global electronics supply chain, as well as the demand for increased visibility and responsiveness in the system. AI also promises measurable savings in time and money. It’s not surprising that the C-suite is optimistic about the future of AI.

References

1: https://www.ascm.org/ascm-insights/5-ways-ai-is-becoming-essential-to-supply-chain

2: https://hbr.org/2023/11/how-global-companies-use-ai-to-prevent-supply-chain-disruptions

3: https://www.xometry.com/resources/blog/manufacturing-resilience-q4-ceo/

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum