Why Use an FPGA SoM for FPGA System Designs?

2024-08-21

The demand for FPGAs is rising with the expansion of applications like data centers, high-performance computers, medical imaging, precise layout traces, specialized PCB materials, form factor constraints, and thermal management. Previously, hardware designers opted for a “chip-down” architecture, selecting specific silicon devices and developing a fully customized circuit board for the application. While this approach results in a highly optimized implementation, it requires significant development time and cost to reach production readiness. To save on time and expense, design teams are now considering more integrated solutions such as Multi-Chip Modules (MCM), System-in-Packages (SiP), Single-Board Computers (SBC), or System-on-Modules (SoM).

The FPGA SoM market is rapidly expanding, enabling a broader range of users to adopt FPGA-based platforms. These SoMs are widely used in various applications due to their adaptable architecture and user-friendly design.

FPGA System on Module overview

An FPGA SoM is a compact compute module designed to be integrated into larger systems, unlike standalone Single Board Computers. It includes essential components such as high-speed DDR memory, flash storage, power management, common interface controllers, and board support package (BSP) software, along with support for high-speed transceiver blocks and multiple communication protocols like Ethernet, USB, and PCIe.

The SoM approach provides significant advantages by offering a pre-built, pre-tested module with core computing parts and software, accelerating development time, reducing costs, and simplifying component sourcing. This allows R&D teams to focus on their company’s specific needs, leading to more predictable design cycles and better business outcomes. Additionally, SoMs offer scalability and flexibility, making it easy to upgrade or modify components without overhauling the entire system. By leveraging SoMs, companies can bring products to market faster, lower the risk of design errors, and improve overall efficiency, making it an attractive solution for various advanced applications.

Time-to-market

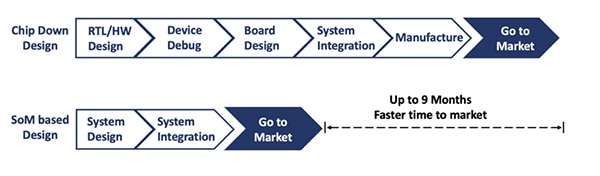

A SoM based approach significantly reduces development time, allowing for faster time-to-market. Since SoMs are pre-tested and qualified by manufacturers such as iWave, designers can integrate these modules into their products more quickly and with fewer errors. This pre-validation ensures that the modules meet high standards of reliability and performance, eliminating the need for extensive in-house testing and troubleshooting. By leveraging SoMs, companies can streamline their development cycles, reducing the time and resources spent on design and validation processes (Figure 1). This enables them to focus on their unique value propositions and core competencies, rather than getting bogged down by the complexities of system integration. The modular nature of SoMs also provides flexibility in the design process, allowing for changes and adjustments even in the later stages of development without significant rework.

Figure 1: Using SoMs can significantly reduce design time resulting in a quicker time-to-market. (Image source: iWave)

Figure 1: Using SoMs can significantly reduce design time resulting in a quicker time-to-market. (Image source: iWave)

Development cost and complexity

Utilizing a production-ready and qualified SoM significantly reduces the complexity of FPGA system design. By integrating pre-tested SoMs into product development, companies mitigate the risks associated with hardware design errors and compatibility issues. This approach not only accelerates time-to-market but also reduces overall development and qualification costs. SoMs undergo rigorous testing regimes, including stringent Electromagnetic Compatibility (EMC) tests and various environmental stress tests such as thermal cycling and aging. These tests ensure that the modules can withstand harsh operating conditions while maintaining reliable performance, thereby minimizing the need for extensive in-house testing and validation efforts.

Product modularity and scalability

One of the primary advantages of adopting a SoM-based approach for FPGA System-on-Chip (SoC) solutions is enhanced modularity and scalability. SoMs are designed to support a wide range of FPGA logic densities, I/O configurations, and transceiver capabilities. This flexibility allows product designers to select an appropriate SoM that aligns with their specific application requirements without needing to redesign the entire hardware architecture. For example, a single carrier board architecture can accommodate different SoM configurations, ranging from smaller FPGAs with basic functionalities to larger, more complex FPGAs with advanced processing capabilities. This modularity facilitates seamless scalability and futureproofing of designs, enabling easy upgrades to newer FPGA generations or additional functionalities as market demands evolve.

Figure 2: An FPGA SoC provides enhanced modularity and scalability. (Image source: iWave)

Figure 2: An FPGA SoC provides enhanced modularity and scalability. (Image source: iWave)

Supply chain and product lifecycle management

Managing the supply chain for FPGA-based systems involves coordinating a multitude of components sourced from various suppliers. A SoM-centric approach simplifies this complexity by consolidating the procurement and supply chain management responsibilities with the SoM vendors, such as iWave. These vendors maintain strategic relationships with key component suppliers and employ proactive forecasting techniques to ensure consistent supply availability and competitive pricing. This proactive management reduces lead times, minimizes procurement risks, and optimizes inventory management, ultimately contributing to cost savings and operational efficiency for companies. Figure 3: A SoM-centric approach simplifies complexity by consolidating the procurement and supply chain management responsibilities. (Image source: iWave)

Figure 3: A SoM-centric approach simplifies complexity by consolidating the procurement and supply chain management responsibilities. (Image source: iWave)

The effective product lifecycle management (PLM) is crucial for maintaining the longevity and competitiveness of FPGA-based products. SoM vendors play a pivotal role in this aspect by continuously monitoring component obsolescence and market trends. They proactively update SoM designs and software packages to incorporate new features, enhancements, and security patches. This proactive approach mitigates the risks associated with component EOL (End-of-Life) announcements, ensuring seamless product continuity and minimizing disruption to customer operations. By entrusting PLM responsibilities to SoM vendors, companies can focus their internal resources on innovation and core competencies, rather than on managing supply chain dynamics and mitigating product lifecycle risks.

Benefits to software developers

Software development for FPGA-based systems can be streamlined and accelerated using SoMs. These modules come equipped with pre-validated Board Support Packages (BSPs) and reference designs, providing a stable and standardized software development environment. Developers can leverage these resources to expedite application software development without the complexities of adapting software to different hardware configurations. This approach not only reduces development cycles but also enhances software reliability and compatibility, allowing developers to focus on optimizing application performance and functionality.

iWave offers a diverse and comprehensive SoM portfolio in collaboration with leading FPGA vendors like AMD, Altera, and Achronix. This partnership grants iWave early access to cutting-edge FPGA technologies, allowing them to develop a wide range of SoMs and Commercial off-the-shelf (COTS) modules tailored to various application needs. For instance, under AMD's Zynq UltraScale+ series, iWave provides multiple options such as the iW-RainboW-G35M, iW-RainboW-G30M, and iW-RainboW-G47M, each offering different configurations suited for different performance requirements. Similarly, with Altera and Achronix, iWave offers SoMs like the iW-RainboW-G58M Agilex 5 SoC FPGA and iW-RainboW-G64M Speedster7T SoM, showcasing their capability to cater to diverse FPGA platforms.

Conclusion

Beyond their SoM portfolio, iWave supports customers with a range of FPGA design services including carrier board design, FPGA IP development, porting, customization, Linux and Board Support Package (BSP) porting, certifications, and mechanical design. Since its inception in 1999, iWave has specialized in embedded systems engineering, serving industries such as Industrial, Medical, Automotive, and Avionics. Their extensive expertise in FPGA and SoC FPGA technologies allows them to provide robust solutions that meet stringent industry standards and enable seamless product development for their global clientele.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.