Why Choose Lever-Based Terminal Blocks in PCB Circuits

Contributed By DigiKey's North American Editors

2025-02-05

Printed circuit boards, the building units of electronic circuits, comprise a number of components. A terminal block is one such part that connects two wires or a wire and a board together in electrical or electronic circuits. Various electrical, mechanical, and other factors dictate the selection criteria for terminal blocks.

The computing ecosystem driving the use of terminal blocks

As more businesses, even those that used to operate traditional manufacturing lines, become data-driven, Industrial IoT (IIoT) is growing to accommodate this change. The number of IoT devices globally is expected to reach 40 billion by 2030.

In addition to the rise of IoT, the following trends are spurring an increased demand in the use of a variety of electrical and electronic components:

- Industry 4.0 and 5.0: IIoT and robots are cornerstones of advanced manufacturing. Both require plentiful sensors and electronic equipment to read machine data and relay information for processing. The growth of industrial automation is fueling demand for electronic circuitry and, correspondingly, terminal blocks.

- AI and edge computing: IIoT operations have routed data to the cloud for processing, but that has been changing with the need for real-time, split-second decision-making. The use of AI at the edge has increased the demand for high-performance computing, which, in turn, calls for sophisticated and complex circuitry.

- Decarbonization and electrification of the economy: As the push toward decarbonization intensifies, more electrical circuits will be pressed into service through a variety of applications—including electric and hybrid vehicles and electric power grids.

Against this broader context of the growth of electrical and electronic circuits, terminal blocks will also register growing demand. The global market for terminal blocks is projected to reach $5.2 billion by 2027, growing at a CAGR of 5.7%.

Connection mechanisms for terminal blocks

Terminal blocks can be classified into different categories, and one of their distinguishing features is the mechanism employed to make connections. A screw-type terminal block uses a screw to hold a wire in place. A push-button mechanism involves pushing a button down, inserting a wire, and releasing the button so the wire clamps into place.

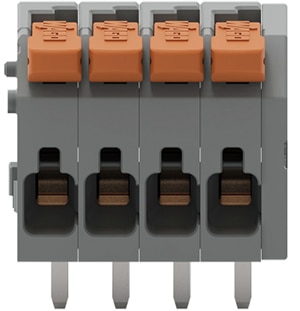

In a push-in style of terminal block, the user simply pushes the wire in, and a spring clamp locks it in place. This is how WAGO’s 2601 Series PCB terminal blocks with levers work using WAGO’s patented Push-In CAGE CLAMP® connection technology. To make the connection, the user pushes the wire into place. To free the wire, the user flips the lever up, easing pressure on the clamp (Figure 1). The simple flip up and flip down operation makes the lever terminal block easy and fast to use.

Figure 1: Levers on terminal blocks help ensure quick and easy connections through a simple mechanism that clamps wires and holds them in place. (Image Source: WAGO)

Figure 1: Levers on terminal blocks help ensure quick and easy connections through a simple mechanism that clamps wires and holds them in place. (Image Source: WAGO)

Advantages of lever-based connections

The lever-operated terminal block offers a significant set of advantages over other locking mechanisms:

- Tool-free operation: Not having to use a screwdriver to tighten wires makes assembly faster and more efficient. Applications that call for frequent wiring changes, such as those in field installations or lab prototyping, particularly benefit from the lever-based terminal block.

- Less strain on wires: Equipment is likely to last longer because wires are not screwed in and, thereby, less subject to wear and tear. Connecting and reconnecting wires is easier and less strenuous on circuits, improving lifespan.

- The right amount of force: Screw-in mechanisms for terminal block connections run the risk of over-tightening. Increased pressure from over-tightening can damage wires faster, decreasing the life of electrical and electronic components. Push-in terminal blocks with a lever release eliminate the need to guess the amount of force required to keep wires in place.

- Stronger and more consistent connections: Screw-in mechanisms also run the risk of loose connections, leading to faulty signals and data loss. Using a terminal block with push-in clamping technology ensures consistent connections that do not change with the technician’s expertise. Consistency and full-contact connections make these terminal blocks particularly useful in high-vibration environments like industrial manufacturing and aerospace.

- Flexibility and compatibility: When integrated with larger electrical circuits, IoT sensors will likely yield a non-uniform mix of wires, all of which need connections to relay data and signals. Using push-in terminal blocks with a lever release is compatible with different kinds of wire—solid, stranded, or fine-stranded.

- User-friendly: Having a lever release for terminal block wires makes it easier to gauge the locked or unlocked state of the connection. Visual and tactile clues make for easier use and decrease the chance for errors when setting up elaborate circuits.

Inspection and maintenance are also easier because of the modular structure of each block unit. Modular designs also allow for faster switching out of wires. Technicians do not have to rip up and replace entire boards when making changes; instead, they can focus on the specific sections that need work and replace modules selectively.

Selecting the right terminal block

As circuitry becomes more complex and in demand, finding the right terminal block for connecting wires will likely focus on units that can perform under extreme environmental conditions and be packed into smaller form factors.

The criteria to consider before choosing a terminal block include the current and voltage the circuits must endure. Designers typically allow some leeway in the numbers (150% of the needed rating) before selecting a product. Pole count determines the number of circuits the terminal block can accommodate. The terminal block’s voltage/current allowance, creepage, etc., determine the block’s pitch, which is the distance between the center of one pole and the next (Figure 2). Finally, designers have to ensure that the housing for the terminal block will accommodate the wires, a size usually specified in American Wire Gauge (AWG).

Figure 2: The terminal block’s pitch, one of the selection criteria for circuit designers, is the distance between the center of one pole and the next. (Image Source: WAGO)

Figure 2: The terminal block’s pitch, one of the selection criteria for circuit designers, is the distance between the center of one pole and the next. (Image Source: WAGO)

Electrical performance must be factored in with mechanical parameters and other metrics before picking a terminal block. For example, WAGO’s 2601 Series PCB terminal blocks with levers are compact and tool-free, allowing quick and easy termination for 26 AWG to 14 AWG wire. Relying on WAGO’s patented Push-In CAGE CLAMP® connection technology, solid and fine-stranded conductors with ferrules are connected by pushing them into the block.

With the ability to be connected vertically or horizontally to the PCB and with a pin spacing of just 3.5 mm, the 2601 series takes up minimal board space. The 2601 series makes WAGO’s selection of lever-equipped PCB terminal blocks ideal for device connections in the field, no matter the performance class. The tool-free wiring is intuitive for worldwide use, and the lever technology ensures that the contact point is always secure. The series finds applications in power supplies, control boards, device manufacturing/device connections, interface modules, sensors, smart homes, and control boards.

Conclusion

Terminal blocks are crucial for establishing the integrity and performance of complex electrical and electronic circuits. When selecting one, design engineers must consider various factors, including the application, voltage and current tolerances, and mechanical connection mechanisms. Push-in terminal blocks with a lever release are especially easy to work with as they deliver quick, consistent and reliable connections.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.