Vehicle Electronics Depend on Ever-Smaller Connectors

Contributed By DigiKey's North American Editors

2024-03-14

Auto manufacturers continually add or improve features and functions to their vehicles, many of which are dependent on electronic control units (ECUs). However, space is limited, prompting a continual drive for miniaturized and more efficient connectors to handle power flow and communications to ensure functioning electronics and electrical systems.

Today's door mirrors are a prime example: It's not unusual for these devices to incorporate motors, blind spot monitoring indicators, turn signal lights, heating elements, ground illuminators, keyless entry system antennas, and even ultrasonic wave generators to blow off water droplets. That's a lot of electronics—all of which must be waterproof and highly resistant to vibrations—contained in a relatively compact housing.

The auto industry is in the throes of a massive transformation, fueled by continuing computerization of features and functions, and massive investments by governments and industry aimed at accelerating a transition away from internal combustion engines.

Vehicles are increasingly-mobile computer systems that automakers envision paving the way to new revenue-generating connected-car services. Advanced driver assistance systems (ADAS), autonomous driving, predictive maintenance, and shared ownership models are also contributing to the shift in emphasis toward software-driven vehicles.

These forces will also impact component suppliers who must adapt amid a highly disruptive transition as automakers fine-tune their strategies to match consumer expectations and demands, which can quickly shift. Several auto manufacturers have accelerated or decelerated their plans to shift to electric vehicles (EVs), for example, and supply chain management remains a persistent issue that can complicate supplier relationships.

One certainty to plan for is the continuing demand for the miniaturization of components as auto manufacturers seek to add more electronics capabilities within an overall vehicle footprint that varies little year to year.

Component suppliers must design smaller products, and they must also plan on increasing the performance of those products as manufacturers seek to take advantage of more ECUs crowding limited space. Connectors—which are often a final thought when designers plan new products—are becoming more critical in the design process as manufacturers look for smaller modules and routing cables.

Going big by getting small and more reliable

Cables and connectors essentially provide the central nervous system and must become more innovative and compact to support the expanding role of computers and sensors. In some cases, traditional connectors in today's vehicles may be larger in size than the modules that depend on them. They must become smaller, more reliable, and enable more flexible configurations in tight and crowded spaces, making them increasingly difficult to service.

The miniaturization of connectors has often been accomplished at the cost of performance, which is unacceptable to manufacturers operating within stringent testing criteria and seeking competitive advantages.

The door mirrors cited earlier illustrate the need for more sophisticated capabilities that raise the technical requirements for connectors. Automotive customers and component suppliers are demanding connectors that save space, carry high currents, improve workability, and resist water and high vibration.

Engineers at JAE Electronics, a global top 10 interconnect supplier, took on the challenge by designing a waterproof automotive connector that provides the performance, design, and flexibility needed to match customer demands for automotive technological advancements.

JAE developed the MX80 Series of automotive in-line pin and socket connectors that correspond to wire sizes of 0.13 to 1.0 mm2 and have an operating temperature range of -40°C to +125°C. Starting with the terminals inside the connectors, engineers evaluated multiple aspects, including spring geometry, current handling, mechanical locking, wire size range, crimp optimization, damage prevention, test probe access, installation and removal, wide operating temperature, sealing, and vibration performance.

After defining those requirements, the JAE team approached the actual connector design, including molding, materials selection, and assembly. Utilizing the company's experience in manufacturing high-quality miniaturized connectors, they set about developing a compact connector with high performance that could meet exacting requirements for water resistance, high currents, and high reliability.

Connector series reconciles retention force and miniaturization

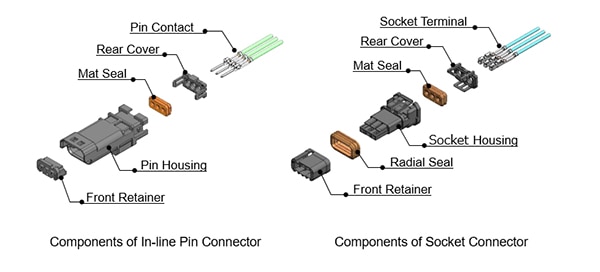

JAE developed two prototype design versions, one of which was focused on ultimate miniaturization, and the second on addressing the reduced retention force resulting from miniaturization. Following these efforts, JAE developed a unique design with a retainer installed in front of the rubber seal to improve retention.

The new design ensures proper harness assembly and terminal retention, and it meets the IPX7 water ingress protection rating to resist water depths of 1 meter for 30 minutes. Also available is a 4-position IPX9K version, capable of withstanding high-temperature, high-pressure water jets.

JAE provides 2, 3, and 4-position in-line pin and socket versions of the MX80 connectors. A 6-position version is available only as a socket-type connector. For added reliability and to prevent incomplete assembly, the connectors incorporate a terminal position assurance (TPA) feature on the housings to detect incomplete terminal insertion. There is also a clear audible click to aid in confirming complete mating.

The MX80 series is suitable for a wide variety of automotive and transportation vehicle applications, including:

- Mirrors and glazing: door mirrors, roof systems, electrochromic glass, and glazing modules

- Lighting: front and rear bumper, fog light, reversing light, stop lamp, license plate illumination, indicator, puddle lamp, and ambient lighting

- Sensor: parking, brake pedal, camera, keyless entry module, tire pressure, and fluid reservoir

- Audio: speaker (anti-rattle and large wire size) and microphone

- Others: suspension, tailgate, doors, and bonnet switch

Among JAE's component portfolio are the 2-pin MX80B02PZ1A (Figure 1) in-line connector and MX80A02SZ1B (Figure 2) socket connector. Also available are the 3-pin MX80B03PZ1A in-line and MX80A03SZ1B socket connectors; the 4-pin MX80B04PZ1A in-line and MX80B04PZ1B socket connectors; and the 6-pin MX80A06SZ1A socket connector. IPX9K-rated connectors are available in 4-pin MX80D04PZ1A in-line and MX80E04SZ1A socket formats.

Figure 1: The MX80B02PZ1A 2-pin in-line connector housing (Source: JAE Electronics)

Figure 1: The MX80B02PZ1A 2-pin in-line connector housing (Source: JAE Electronics)

Figure 2: The MX80A02SZ1B 2-position socket connector. (Source: JAE Electronics)

Figure 2: The MX80A02SZ1B 2-position socket connector. (Source: JAE Electronics)

The JAE MX80 Series are compact, waterproof in-line connectors with an extensive range of power-carrying capabilities, depending on the wire size chosen: 0.75 ~ 1.0 mm2, 0.3 ~ 0.5 mm2, and 0.13 ~ 0.22 mm2. With a 0.13 mm2 wire size, 2-pin connectors are rated at 4.2 A, 3-pin at 3.7 A, and 4-pin at 3.6 A. With 0.35 mm2 wire size, those ratings are, respectively, 7.1 A, 6.4 A, and 5.4 A, and for 1.0 mm2 wire, the respective ratings are 10.3 A, 10.0 A, and 9.5 A.

The connectors are environmentally tested to the USCAR-2 V2 performance standard for automotive electrical connector systems and the LV214 (severity 3) connector test standard. They feature the ISO/JASO/EWCAP/VDA standard 0.64 mm tab size, are compatible with 2.54 mm pitch pin contacts, and incorporate an integrated bracket on pin housings to support chassis fastening vehicle clips.

Rear covers, housings, and front retainers (Figure 3) are molded from polybutylene terephthalate and glass fiber (PBT-GF10) material. Seals are silicon rubber. JAE offers contacts (sold separately and not integrated at the time of delivery), including the MX80S08K3F1, made with copper alloy material and a tin plating finish. Dummy plugs to seal off unused cavities are available both in IPX7 (MX80A000XD1) and IPX9K (MX60A000XD2) rated versions.

Figure 3: Expanded views of MX80 in-line pin and socket connectors. (Source: JAE Electronics)

Figure 3: Expanded views of MX80 in-line pin and socket connectors. (Source: JAE Electronics)

JAE also offers an MX81 Series of non-waterproof compact connectors, suitable for connecting in-vehicle electronic devices such as ECUs and sensors. The MX81 connectors, including the MX81A002SF1, utilize the same socket terminals as the MX80 Series of waterproof connectors. This enables utilization of the same terminals and crimp tools for a broad range of waterproof and non-waterproof areas of the vehicle.

Conclusion

Motor vehicle manufacturers want to add more electronics-enhanced features and functions into existing spaces. Product designers who can leverage a new breed of more compact and efficient connectors will be able to deliver smaller components with greater performance, providing manufacturers with more flexibility to meet market demands.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.