Using Light Curtains to Enhance Safety and Measure Objects

Contributed By DigiKey's North American Editors

2024-07-12

Light curtains are a versatile technology. While they are often associated with safety applications, they have a multitude of uses, including machine guarding and establishing protected zones; material handling to detect the presence of objects or measure the size of passing objects; ensuring the proper positioning or alignment of objects for packaging and sorting applications; and intrusion detection and access control for restricted areas.

For a comparison of light curtains and safety laser scanners, along with a review of scanner applications, see part 1 of this series, “How Safety Laser Scanners Can Protect People and Machines.”

This article begins by looking at important light curtain specifications and performance standards, presents application examples of how light curtains are used in safety and access control systems, and how measuring light curtains operate. Along the way, it presents exemplary light curtains from Panasonic, IDEC, Omron, and Banner Engineering.

Safety light curtain standards and types

Four types of safety performance are defined in International Electrotechnical Commission (IEC) 61496, Safety of machinery - Electro-sensitive protective equipment (ESPE). The relevant types are 2, 3, and 4. Type 1 is not defined for safety light curtain applications.

IEC 61496 adds another layer of requirements on top of the definitions of Safety Integrity Levels (SILs) in IEC 61508 and International Organization for Standardization (ISO) 13849, which defines performance levels (PLs).

SILs are ranked from 1 to 3, with SIL 3 being the highest level, and PLs are ranked from “a” to “e”, with PLe being the most demanding. Using the classifications in IEC 61496, light curtains generally fall under Types 2 and 4, although a few are rated as Type 3 devices. Safety laser scanners meet the requirements of Type 3. Some important factors in the Type classifications include:

Type 2 devices must meet SIL 1 and PLc. They are intended for use in lower-risk applications where faults can result in injuries like bumps or bruising, knockdowns, minor cuts, and abrasions, or trapping but not crushing. IEC 61496 requires the device to perform a self-check during startup and periodically during operation. These devices lack the redundant automatic self-checking circuits in Type 4 light curtains. The effective aperture angle (EAA) that defines the field of view must be ±5 degrees or narrower. That can result in the possibility of optical interference and errors.

Type 3 ESPEs like safety laser scanners and a few light curtains must meet SIL 2 and PLd and are “designed to not fail to danger due to a single fault but can fail to danger due to an accumulation of faults.” These devices also have more stringent electromagnetic compatibility (EMC) requirements than Type 2 devices. Type 3 devices are suitable for applications where safety is a significant concern.

Type 4 light curtains are designed where safety is a major consideration. They must meet the highest standards, PLe and SIL 3. They are designed “to not fail to danger due to a single failure or an accumulation of faults.” They have a smaller EAA of ±2.5 degrees, making them less susceptible to optical interference and able to recognize objects more readily. They are required to meet the most severe EMC requirements.

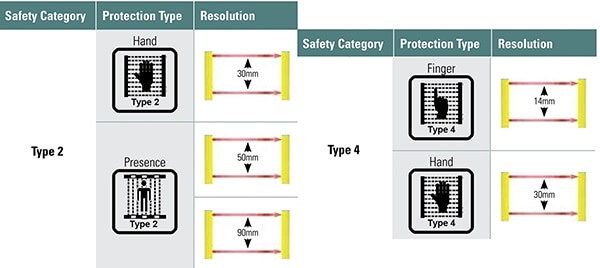

Type 2 light curtains are up to 30% lower in cost than Type 4 light curtains due to the less expensive optics and simpler fault detection circuitry. Type 4 light curtains are available in a wider range of resolutions, including 14 mm for identifying fingers, 30 mm for hands, 50 mm for legs, and 90 mm for the presence of a body. In contrast, Type 2 light curtains are generally limited to larger resolutions (Figure 1).

Figure 1: Type 4 light curtains are typically available with smaller minimum resolutions than type 2 units. (Image source: IDEC)

Figure 1: Type 4 light curtains are typically available with smaller minimum resolutions than type 2 units. (Image source: IDEC)

In addition to detecting different-sized objects, the beams in a light curtain can be individually controlled to provide more advanced functions like muting, blanking, and measuring the size and number of objects.

Muting and blanking light curtains

Muting and blanking a light curtain refers to turning off all or a part of the light curtain under specific circumstances. Muting is an automatic process that suspends all or part of a light curtain’s protection and typically occurs during a non-hazardous part of the machine cycle. It can allow materials to enter a work area without stopping any hazardous activity. Once the material has entered the work area, the light curtain’s full protective functionality is restarted.

Typical applications for muting include:

- Enabling the entry/exit of pallets on a palletizing machine between operations

- Allowing material to move between areas in an automated manufacturing process while still protecting personnel when the machines are active

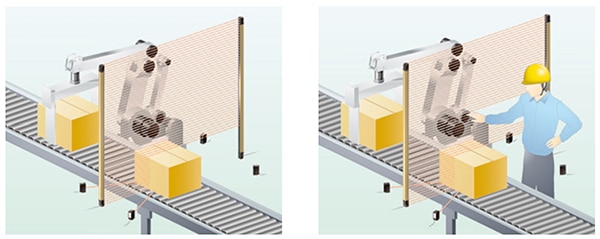

Figure 2: Using muting a light curtain will allow specific-sized objects through without interrupting machine operation (left) but will detect other objects like a hand or fingers (right) and stop the machine. (Image source: Panasonic)

Figure 2: Using muting a light curtain will allow specific-sized objects through without interrupting machine operation (left) but will detect other objects like a hand or fingers (right) and stop the machine. (Image source: Panasonic)

Blanking involves turning off a portion of the light curtain without stopping the machine from being protected. It can also allow people limited access to an area during a safe period. Typical applications for blanking include:

- Reaching in to load or unload a robotic workstation during a safe period

- Accessing a hydraulic punch press during the up-cycle

Type 2 light curtain

Type 2 SG2 series light curtains from IDEC are available in hand and presence protection models. For example, model SG2-90-030-OO-X is designed for presence detection with a control height of 300 mm and a resolution of 90 mm. It includes a test/restart function and an integrated alignment system to speed deployments. The rotating mounting brackets further speed installation and the alignment of the emitting and receiving units easily, even in applications that use mirrors or operate over distances up to 19 m.

Muting and blanking in harsh environments

Safety light curtain applications in cold storage warehouses with temperatures down to -30°C, metal working processes like stamping machines that need IP67G oil-proof ingress protection, and other operations in harsh dusty and dirty environments like automotive manufacturing and machine tools can turn to the F3SG-SR series from Omron. These Type 4 light curtains include muting plus fixed and floating blanking functions.

F3SG-SR light curtains have protective heights from 160 mm to 2,480 mm. When detection of hands or other objects 25 mm in diameter is needed, safety system designers can turn to the F3SG-4SRA0280-25-F that supports flexible lengths in increments of 40 mm up to 1,000 mm using 27 beams in a protective height of 280 mm (Figure 3).

Figure 3: This light curtain supports flexible lengths in increments of 40 mm with a protective height of 280 mm. (Image source: Omron)

Figure 3: This light curtain supports flexible lengths in increments of 40 mm with a protective height of 280 mm. (Image source: Omron)

Resists twisting, warping, and impact

When a light curtain is used where it could be subjected to impacts and twisting, system designers can turn to the SF4D series Type 4 light curtains from Panasonic. The 630-mm long model SF4D-H32-0 has an IP67 rating, 25 mm resolution for hand protection, and integrated blanking and muting functions.

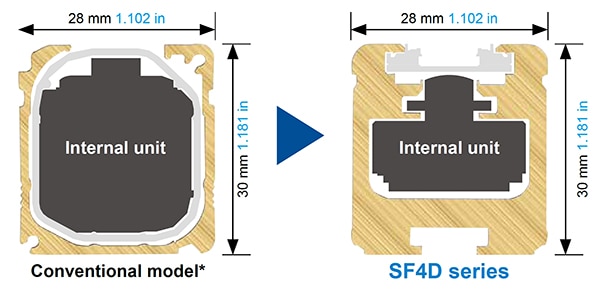

A key to the ruggedness of these light curtains is the redesigned internal unit that enabled the case to be optimized for robustness and rigidity. The internal unit occupies less than 40% of the volume of previous models, enabling a substantial increase in case thickness (Figure 4). Even though the internal unit is smaller, the optical output has been increased and the OFF response time of the control outputs is 10 ms or less, or 18 ms or less when connected in series or in parallel.

Figure 4: The more compact inner unit supports higher optical output while enabling a significantly thicker housing. (Image source: Panasonic)

Figure 4: The more compact inner unit supports higher optical output while enabling a significantly thicker housing. (Image source: Panasonic)

Measuring with light curtains

Light curtains designed for measuring objects typically have three modes: straight scanning, single-edge scanning, and double-edge scanning. Key specifications include the minimum object detection size (MODS) and the edge resolution (ER).

Straight scanning is usually the default mode, and the beams are sequentially scanned from the display end to the opposite end of the array. When the first unblocked beam is encountered, the measurement is determined. Typical sensitivities for straight scanning using low contrast mode are a MODS of 5 mm and an ER of 5 mm. If high-excess-gain scanner mode is used, the MODS is 10 mm, and the ER is 5 mm. Single- and double-edged scanning can provide a MODS of 10 mm and an ER of 2.5 mm.

Single-edge scanning begins with the first (lowest) beam being blocked, indicating the presence of an object. The curtain then checks the middle beam. The scanner looks at the bottom quarter beam to see if the middle beam is unblocked. The scanner looks at the top quarter beam to see if the middle beam is blocked.

Once it’s determined whether the top or bottom quarter beams are blocked or unblocked, dividing the number of beams in half continues until the top edge of the object has been found.

In circumstances where the first beam is not necessarily blocked, double-edge can be used and starts with the selection of step size, usually 1, 2, 4, 8, 16, or 32, depending on the application. It begins with the curtain activating beam 1. If that beam is blocked, the first edge has been identified. If it’s not blocked, the curtain activates the next beam, which is determined by the step size. For example, if the step size is 4, beam 5 is activated.

If the activated beam is unblocked, the curtain continues the stepping process until a blocked beam is found. At that point, a binary search back toward the start is used to identify the first blocked beam and the corresponding edge is identified. The process is repeated, this time using the identified edge as the reference point and the stepping process to identify an unblocked beam, then backtracking to find the highest number beam that’s blocked, identifying the second edge.

Figure 5: Example of beam sequences in a double-edge scan. (Image source: Banner Engineering)

Figure 5: Example of beam sequences in a double-edge scan. (Image source: Banner Engineering)

Light curtains for measuring

The A-GAGE EZ-ARRAY measuring light screens from Banner Engineering are designed for applications like real-time product sizing and profiling, edge-guiding and center-guiding, hole detection, parts counting, and so on. Emitters and receivers range from 150 to 2400 mm (5.9 to 94.5 in) long (Figure 6). For example, model EA5E600Q is 600 mm (23.6 in) long with 120 beams. These light curtains support precise high-speed process monitoring and inspection, profiling, and web-guiding systems. Additional features include:

- Numerous scanning options:

- 16 scan analysis (measurement) modes

- Three scanning methods

- Selectable beam blanking

- Six-position DIP switch for setting scan mode, measurement mode, analog slope, and setting the discrete for complementary measurement or alarm operation.

Figure 6: The A-GAGE EZ-ARRAY family of measuring light curtains is available in lengths from 150 mm to 2400 mm. (Image source: Banner Engineering)

Figure 6: The A-GAGE EZ-ARRAY family of measuring light curtains is available in lengths from 150 mm to 2400 mm. (Image source: Banner Engineering)

Conclusion

Light curtains can do much more than simply prevent access to dangerous and sensitive areas, protecting both people and machines. They can support controlled access using blanking and muting functions to increase productivity. Light curtains can also support non-contact measurement techniques that quickly and efficiently measure multiple dimensions of objects.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.