Using DAQs to Unlock High-Speed Precision in Industrial Motion Control

Contributed By DigiKey's North American Editors

2025-07-23

Modern industrial systems, such as robotics and automated conveyors, rely on high-speed, synchronized data to optimize performance, enhance efficiency, and facilitate predictive maintenance. However, capturing and coordinating position and motion data with millisecond-level precision presents a significant challenge. Standard data acquisition (DAQ) systems often lack the specialized functions needed to accurately interface with encoders and timers in real time, which can compromise system reliability and lead to performance bottlenecks.

This article outlines the requirements for implementing high-speed position and timing measurements in demanding industrial applications. It then introduces an encoder counter/timer module from Advantech and shows how its multiple encoder modes and four high-speed channels can be used to address complex synchronization challenges in robotics and motion control applications. A typical system setup, along with compatible software tools, provides a clear path for integration.

The importance of precise motion and timing in industrial processes

Modern industrial systems rely on complex, sequenced movements, where coordination is crucial. Consider a robotic arm tasked with picking components off a moving conveyor. For the system to work, the robot’s motion must be synchronized with the conveyor’s speed and position. This requires capturing and coordinating data from multiple sources with millisecond-level precision, a challenging technical requirement.

A DAQ system plays a central role in solving this problem. The system captures encoder data from the conveyor’s drive motor and the robotic arm’s joints, synchronizing these measurements across multiple channels so that the exact moment of interception can be calculated.

As conveyor speeds increase to boost throughput, the DAQ system must sample position and timing data quickly to avoid errors. A delayed or missed sensor reading can lead to mistimed operations or even collisions between mechanical components, resulting in unscheduled downtime and lost productivity.

Precision DAQ systems also support predictive maintenance. For instance, speed anomalies or position errors might indicate problems such as worn bearings or a slipping belt. By analyzing these signals, designers can identify potential failures before they disrupt operations.

High-speed DAQ requirements

To serve this type of application, a DAQ system must meet several demanding performance characteristics:

- High-speed, high-resolution sampling: Capturing fine motion details, such as sub-millimeter changes in position, demands both high sampling rates and precise resolution. Sampling in the megahertz (MHz) range ensures that no critical events are missed, even in high-speed environments.

- Simultaneous, multi-channel sampling: To coordinate a robotic arm and a conveyor, their respective position and timing data must be captured simultaneously, not sequentially. Attempting to correlate data streams captured sequentially can lead to errors, where the wrong item is picked or missed entirely.

- Flexible encoder support: Industrial systems often use components from different vendors, resulting in a mix of encoder signal types. A DAQ system should support a wide range of encoder modes to eliminate the need for additional interface logic.

- Ruggedization: Industrial environments expose electronics to electromagnetic interference, vibration, and heat. DAQ hardware must be specified for reliable operation under these conditions to prevent system failures.

- Scalability: The DAQ system should be modular, allowing designers to easily expand it by adding more channels or different input types. This supports the integration of new robots, sensors, and production lines as an automated facility grows.

Meeting this diverse set of requirements presents a significant design challenge. While many DAQ systems are well-suited for general-purpose data capture, applications that involve high-speed, synchronized motion require specialized hardware.

Advanced position and timing measurement for motion control systems

The iDAQ-784 high-precision encoder counter/timer module (Figure 1) from Advantech is specifically designed to meet these requirements. This module features four general-purpose, 32-bit encoder channels that support synchronous position and timing measurements across an industrial system. It supports a maximum input frequency of 10 MHz for precise timing of encoder signals.

Figure 1: The iDAQ-784 encoder counter/timer module enables simultaneous data acquisition across four 32-bit channels for complex industrial motion applications. (Image source: Advantech)

Figure 1: The iDAQ-784 encoder counter/timer module enables simultaneous data acquisition across four 32-bit channels for complex industrial motion applications. (Image source: Advantech)

Built-in digital signal filtering helps the iDAQ-784 provide enhanced signal clarity and measurement accuracy. This enables high-precision system characterization for advanced automation applications such as industrial robotics, motion control, and high-speed conveyor systems.

Encoder input, measurement, and output modes

The iDAQ-784 supports a variety of input signal types and measurement modes, accommodating diverse industrial motion control requirements. Each of the four counter channels accepts both single-ended and differential inputs, with a ±15 volt DC (VDC) common-mode range. The module supports three industry-standard encoder types for position measurement:

- Quadrature (A/B phase): Two out-of-phase channels (A and B) are used to determine both position and direction. The specific encoding (X1, X2, or X4) determines the resolution by counting rising and/or falling edges, with X4 providing four times the resolution of X1.

- Two pulse (CW/CCW): Separate input lines are used for clockwise (CW) and counterclockwise (CCW) pulses. The counter increments on CW pulses and decrements on CCW pulses.

- Pulse direction (signed pulse): One signal is used for pulses, and a second signal indicates direction. The counter increments or decrements based on the direction signal state.

Each encoder input can be wired single-ended or differentially, and a Z signal input is available for position reset. Each counter channel also supports multiple functional modes for timing and pulse generation:

- Event counting: counts rising or falling edges of an input signal, optionally gated

- Frequency measurement: measures signal frequency using either period inversion or pulse counting methods

- Pulse width measurement: measures the duration of high and low states of a digital signal

- Position measurement: tracks encoder position using the supported input modes above

- Continue compare (position compare): triggers an output pulse or interrupt when a position threshold is reached

- One-shot (delayed pulse generation): outputs a single pulse after a gate trigger and specified delay

- Timer/pulse generation: outputs a continuous pulse train with interrupt support

- Pulse-width modulation (PWM): outputs a waveform with programmable high and low durations; supports finite or continuous generation

This wide range of modes ensures compatibility with the various devices commonly found in an industrial system.

Designed for industrial environments

The iDAQ-784 and the surrounding ecosystem are designed to provide reliable performance in demanding industrial settings. The module is rated for a wide operating temperature range of –40°F to 158°F and up to 90% relative humidity (non-condensing).

The module is also designed to combat the electromagnetic noise commonly found in factory environments; it features built-in digital signal filtering to enhance signal clarity, and each channel supports differential signal inputs for excellent common-mode noise rejection.

This design philosophy extends to ecosystem accessories, which feature rugged designs built to DIN-rail standards for secure installation inside industrial cabinets. This combination of environmental hardiness, noise immunity, and rugged physical integration enables high-precision system characterization for advanced automation applications.

Building a high-speed, high-precision DAQ system

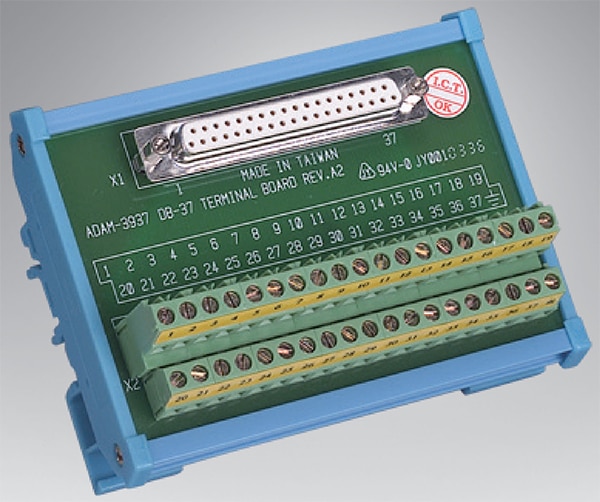

The first step in building the DAQ system is physically connecting the sensors. This process begins by connecting the sensor leads to a terminal block. The Advantech ADAM-3937-BE interface module (Figure 2) is a ready-made solution for this purpose. This 37-position block is designed for DIN-rail mounting and measures 87.2 mm × 112.5 mm × 51 mm to support ease of integration with standard, DB37-compatible industrial infrastructure.

Figure 2: The ADAM-3937-BE DIN-rail wiring board presents a universal interface solution for DB37-compatible hardware. (Image source: Advantech)

Figure 2: The ADAM-3937-BE DIN-rail wiring board presents a universal interface solution for DB37-compatible hardware. (Image source: Advantech)

From this terminal block, signals can be routed to the iDAQ-784 via a cable assembly such as the PCL-10137-1E (Figure 3). This 3.28 ft., 37-pin, D-sub cable features thumbscrew fasteners for a sturdy connection. The aluminum/mylar foil and braided copper double-shielded construction supports signal integrity in electromagnetically noisy environments, typical of industrial motion applications. Longer variants are also available.

Figure 3: The PCL-10137-1E cable assembly features male 37-pin D-sub connectors for interfacing with the iDAQ-784. (Image source: Advantech)

Figure 3: The PCL-10137-1E cable assembly features male 37-pin D-sub connectors for interfacing with the iDAQ-784. (Image source: Advantech)

The iDAQ modular ecosystem encompasses a diverse range of specialized I/O modules and terminal blocks, enabling designers to construct a rugged and scalable DAQ system tailored to their specific requirements.

iDAQ software tools

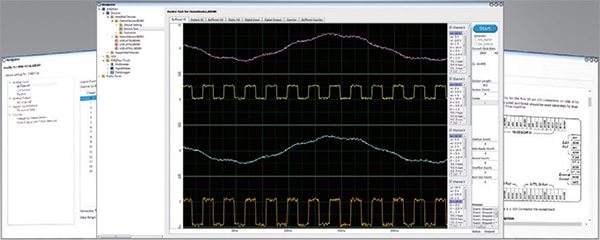

Once the hardware is assembled, the iDAQ system is programmed using the DAQNavi Software Development Kit (Figure 4), a free development environment. DAQNavi features a utility called Advantech Navigator, which enables designers to configure and function-test iDAQ devices without any programming. It can also be used to simulate devices, allowing designers to program and run applications without a physical DAQ device for flexible system development.

Figure 4: The free DAQNavi software environment is used with the iDAQ system. (Image source: Advantech)

Figure 4: The free DAQNavi software environment is used with the iDAQ system. (Image source: Advantech)

DAQNavi supports host systems running 32- and 64-bit Windows operating systems, as well as several popular Linux distributions. Because the API functions remain the same across both platforms, migration requires no program modification, supporting future-proof integration. DAQNavi is compatible with many commonly used programming languages, including C#, C++, Visual Basic, Java, MATLAB, and LabVIEW, to facilitate user adoption.

Conclusion

Precise timing and synchronization are crucial for advanced robotic and industrial operations, enabling process optimization while maximizing equipment uptime and production efficiency. The Advantech iDAQ-784 module, along with its complete iDAQ ecosystem, offers a rugged and scalable solution to meet these high-performance demands.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.