Using a Unified Cybersecure Platform to Support Comprehensive Industry 4.0 Connectivity

Contributed By DigiKey's North American Editors

2024-04-30

A unified and cybersecure Industry 4.0 deployment requires multiple levels of connectivity. The first level of connectivity starts on the factory floor with the control of individual devices, including machines and robots, sensors, and traceability solutions. The second level of connectivity extends to mid-level automation with human-machine interfaces (HMIs) and machine-to-machine communication. The highest level of connectivity links with the company’s information technology (IT) and operations technology (OT) systems to coordinate overall logistics and maximize efficiency and productivity.

Satisfying diverse connectivity needs requires an automation platform that supports multiple open protocols like EtherCAT, Safety over EtherCAT (also called FailSafe over EtherCAT or FSoE), EtherNet Industrial Protocol (EtherNet/IP), common industrial protocol (CIP) Safety, and IO-Link for connecting machines, machine controls, sensors, vision systems, safety devices, and HMIs.

The Open Platform Communications Unified Architecture (OPC UA) protocol is needed to support data consolidation, sharing, and secure visibility across the enterprise. Finally, a software platform is required that integrates configuration, programming, simulation, and monitoring with an intuitive interface, allowing engineers to manage process control, motion, safety, vision, and robotics in one system.

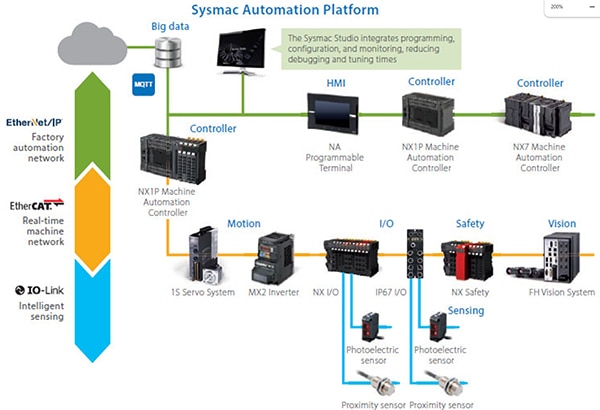

This article first presents a diagram of the levels of connectivity in Industry 4.0 automation systems (Figure 1). It then uses product examples from Omron Automation to move through the various levels of automation from IO-Link and intelligent sensing to EtherCAT for vision systems and real-time machine control, EtherNet/IP for factory automation networks, and how OPC UA links the factory to higher-level enterprise networks and the cloud using Message Queuing Telemetry Transport (MQTT) and other standard protocols. It closes with a look at how Omron’s Sysmac Studio software ties it together.

Figure 1: Levels of connectivity used in Industry 4.0 automation systems from IO-Link on the factory floor to MQTT and OPC UA reaching higher-level enterprise systems and the cloud. (Image source: Omron Automation)

Figure 1: Levels of connectivity used in Industry 4.0 automation systems from IO-Link on the factory floor to MQTT and OPC UA reaching higher-level enterprise systems and the cloud. (Image source: Omron Automation)

Safety, sensors, and servos

At the automation network level closest to the factory floor, sensors, safety controllers, motor drives, and servos are found and have specific connectivity requirements. IO-Link supports intelligent sensing, and EtherCAT links the various motion, I/O, safety, and vision subsystems into a real-time machine network.

I/O units

It takes a wide range of I/O units to support the diversity of sensors in Industry 4.0 factories. Omron’s Sysmac NX I/O Units include over 120 models and support a wide range of protocols, including IO-Link for connecting to sensors and EtherCAT and EtherNet/IP for linking with motion, safety, vision, and other controllers. These I/O units also support FSoE and CIP Safety protocols.

Safety controllers

Safety is a crucial consideration when working with factory automation. Omron offers the NX Integrated Safety Controllers that support robust safety systems that meet PLe according to EN 13849-1 and SIL3 according to IEC 61508, including FSoE connectivity. In addition, EtherNet/IP coupler units like the NX-EIC202 can link NX Integrated Safety Controllers with an EtherNet/IP multivendor network, the NX-series I/O Units, and other safety units.

The safety CPU can control up to 128 safety I/O units. The safety units can be used with any combination of standard NX I/O units. Further increasing deployment speed and flexibility, safety programs can be standardized and reused efficiently using program organization units (POUs) defined in IEC 61131 for design and operation.

AI-based vision

Artificial intelligence (AI) based automated vision systems can boost productivity across a wide array of Industry 4.0 applications like robot guidance, code reading and verification, color inspection, counting, defect identification, optical character recognition (OCR), and optical character verification (OCV), and presence/absence detection.

Developing and deploying AI-based vision systems can be a complex and time-consuming activity. Omron’s FH series includes the hardware and software needed to implement various AI-based vision applications quickly.

For example, the model FH-2050 can support two cameras. Additionally, like other models in the FH series, it boasts a wide range of connectivity options, including EtherCAT, EtherNet/IP, Ethernet TCP/IP, PROFINET, serial RS-232C, and universal serial bus (USB), enabling it to fit into many locations in Industry 4.0 factories seamlessly.

In the case of mass customization, a hallmark of Industry 4.0 production lines, automated visual inspection can be challenging to implement. Until recently, experienced human inspectors were required to identify product defects. Today, AI has reached a level of capability where it can recognize object features and defects, ranging from blemishes to scratches, as well as human inspectors. In addition, AI can include machine learning to support continuous improvement and adaptation to new requirements.

Servos

Servos and drives are an integral part of Industry 4.0 factories. Omron’s 1S servo technology supports units from 50 W to 15 kW. For example, model R88D-1SN15H-ECT is a 1.5 kW servo drive rated for 200 to 240 Vac single and three-phase input power. It’s compatible with the R88M-1L1K530T-BS2 servo, rated for 1.5 kW and 3,000 revolutions per minute (rpm) with 4.77 Newton-meters (Nm) of torque. Like all 1S servos, this unit features:

- High-resolution multi-turn 23-bit encoder

- Direct motor brake control with an embedded relay

- Built-in safety functions

- Hardwired safe torque off that meets PLe according to EN ISO 13849-1 and SIL3 according to IEC 61508

- FSoE safe torque off that meets PLd according to EN ISO 13849-1 and SIL2 according to IEC 61508

Both the hardwired and FSoE safe torque off meet EN61800-5-2(STO). A hardwired solution can bring the line to a standstill by cutting main power. FSoE supports more nuanced responses and can send a Safe Operating Stop command, only slowing the motors in the affected area. FSoE can also send a Safe Stop command, stopping the motors when needed.

Machine controllers

Machine controllers like the NX1P2 series from Omron can fulfill two functions. They can be used to directly control various servos and other machines on the EtherCAT level of real-time machine control, and they can provide a link up to the EtherNet/IP factory automation level.

These controllers support integrated sequence and motion control and connect to up to eight controlled axes using EtherCAT (Figure 2). They also feature EtherCAT control network support and EtherNet/IP connectivity for linking to factory automation controllers. They have slots for two option boards providing expanded connectivity, including serial communications and analog I/Os. These controllers fully conform with IEC 61131-3 programming standards to simplify and speed commissioning.

Figure 2: NX1P controllers can use EtherCAT connectivity to support up to eight axes of motion, like eight 1S AC servo drives. (Image source: Omron Automation)

Figure 2: NX1P controllers can use EtherCAT connectivity to support up to eight axes of motion, like eight 1S AC servo drives. (Image source: Omron Automation)

Omron’s NX1P is an essential all-in-one controller that can manage advanced motion, vision, safety I/O, networking, and IoT connectivity. For more complex machine control applications that can benefit from up to 254 CIP safety connections, up to 62 axes of motion, 256 EtherCAT nodes, 1 Gbps EtherNet/IP ports, and OPC UA, network designers can turn to the Sysmac NX502 controllers.

Advanced machine control

The NX502 controllers are suited for use at the EtherCAT and EtherNet/IP network levels, and they include MQTT, OPC UA, and structured query language (SQL) capability for connecting to the company’s IT and OT systems and the cloud.

NX502 controllers have slots for up to four EtherNet/IP (EIP) expansion cards with data Transfer rates up to 1 Gigabit per second (Gbps). Each EIP card creates a subnet, increasing the number of machines that can be controlled and segmenting the machine-level network from the database network and the factory-level network. Network segmentation also reduced cyber-attack risk by limiting access to the different subnets.

These controllers sit at the apex of the network architecture and support a variety of control, information, and safety functions, including (Figure 3):

- Control

- Up to 32 axes of motion with 250 μs cycle time

- Servo control with up to 64 axes

- 80 MB program storage

- 260 MB variable storage

- Information

- OPC UA provides secure connectivity for manufacturing execution systems (MES) and enterprise resource planning (ERP) systems

- SQL functionality supports fast and reliable direct access to databases and communication of production data

- MQTT supports direct connection to the cloud and secure data collection

- Up to 10 x 1 Gbps EtherNet/IP ports for high‐speed, high‐capacity communications with expansion unit

- Safety

- Up to 8 CIP Safety networks for network modularization and safety control across production lines

- Up to 254 FSoE connections for high speed and high-reliability safety in large production lines

Figure 3: NX502 controllers (center) can combine all the functions needed to implement Industry 4.0 automation networks. (Image source: Omron Automation)

Figure 3: NX502 controllers (center) can combine all the functions needed to implement Industry 4.0 automation networks. (Image source: Omron Automation)

Human-machine interface

The NA series advanced programmable terminal/HMI provides operators and network engineers reliable and convenient access to Sysmac automation devices and networks. These wide-screen terminals have two Ethernet ports supporting simultaneous access to a control device and maintenance activities. They are programmable, making it simple to implement custom user interfaces.

These HMIs are available in sizes of 7”, 9”, 12”, and 15” to fit a wide range of application needs. The 12” and 15” models have 1,280 x 800 pixels, while the 7” and 9” models have 800 x 480 pixels. Operators wearing gloves can use their resistive touch screen, which can be made waterproof if needed. The function keys can be programmed to simplify user interactions (Figure 4).

Figure 4: These programmable HMIs feature two Ethernet ports and can be made waterproof. (Image source: Omron Automation)

Figure 4: These programmable HMIs feature two Ethernet ports and can be made waterproof. (Image source: Omron Automation)

Cybersecure software

Sysmac Studio includes comprehensive and cybersecure software tools for designing, verifying, and operating industrial networks. It enables network designers to integrate logic, motion and drives, robotics, safety, visualization, sensing, and information technologies. Some key capabilities during design and verification include (Figure 5):

- Automatic programming based on truth tables with input, output, and stop conditions of safety devices

- User-defined function block (FB) to support help files to describe input and output conditions and program functionality; can have different security levels to protect them from unauthorized changes

- Offline simulation performed on a separate computer without connecting actual hardware

- Online functional testing of integrated safety functions; test results can be output as a report

Figure 5: Sysmac Studio software provides comprehensive support for designing, verifying, and operating Industry 4.0 automation networks. (Image source: Omron Automation)

Figure 5: Sysmac Studio software provides comprehensive support for designing, verifying, and operating Industry 4.0 automation networks. (Image source: Omron Automation)

Sysmac Studio software also supports ongoing operations and maintenance. Downtime is minimized using an SD memory card containing logging settings and safety data logging. This data enables network technicians to efficiently determine the cause of an unexpected system stoppage and take appropriate preventative and corrective measures.

The safety unit restores an automatic configuration restart to reduce maintenance:

- Restore programs and settings are stored on an SD card in the safety unit. When a safety controller unit is replaced, the stored programs and settings can be quickly copied to the new unit.

- When a safety I/O unit is replaced, automatic configuration restart automatically downloads the setting data into the new unit.

Conclusion

Sysmac automation devices and software from Omron support the complete connectivity needs for Industry 4.0 factory automation networks. Their capabilities extend from IO-Link for connecting to sensors and EtherCAT and EtherNet/IP for linking with motion, safety, vision, and other controllers. They include support for FSoE and CIP Safety protocols. Powerful controllers and software that use OPC UA, SQL, and MQTT are available to link the factory network to the company’s IT and OT systems as well as the cloud.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.