Use Soft-Starter Units to Solve Motor Power-Up and Cybersecurity Issues

Contributed By DigiKey's North American Editors

2024-03-21

Three-phase asynchronous motors powered by the AC line and rated at tens to hundreds of horsepower (HP) are the driving force of many commercial and industrial applications. They typically have motor-drive currents spanning about 10 amperes (A) to over 1000 A at line voltages from just over 200 volts AC (VAC) to as high as 700 VAC. The problem for designers is that when starting, they draw large inrush currents that can damage the motor and affect the load.

A soft-starter control unit between the AC line and the motor controls this inrush current by managing motor startup acceleration and torque, thus optimizing motor performance and minimizing undesired consequences. More advanced soft starters add sophisticated features to maximize performance, provide electrical and thermal protection, include a robust suite of connectivity options, and protect against cyberattacks.

This article outlines the functions of a soft starter. It then introduces and shows how to apply the Altivar Soft Starter ATS480 control units from Schneider Electric.

Soft-starter functions

A soft starter is used with a motor to reduce the inrush current and control torque during startup for a transitional period. It gradually increases the voltage applied to the motor, which results in smooth acceleration with minimal jerk (the rate of change of acceleration).

Starters usually offer a provision to allow user adjustment of the starting torque and acceleration time to suit different applications. They can significantly reduce the starting current to achieve breakaway and hold back the current during acceleration.

Newer soft starters offer additional features that increase efficiency, maintain high power factor (PF) using dynamic PF correction, enhance electrical safety, detect line and motor anomalies, provide network connectivity, and address cybersecurity concerns.

An example of the capabilities and features of state-of-the-art soft starters is the Altivar Soft Starter ATS480 series from Schneider Electric (Figure 1).

Figure 1: The Altivar Soft Starter ATS480 series adds many advanced features to its core function. (Image source: Schneider Electric)

Figure 1: The Altivar Soft Starter ATS480 series adds many advanced features to its core function. (Image source: Schneider Electric)

These units incorporate six thyristors and a torque control algorithm to control acceleration, deceleration, and stopping of three-phase, squirrel-cage asynchronous motors up to 900 kilowatts (kW). The broad span of models in this series supports operating voltages from 208 to 690 volts and currents from 17 to 1200 A. All units meet worldwide standards, certifications, and regulatory mandates that define performance, safety, efficiency, electromagnetic compatibility (EMC), pollution grade, and shock and vibration.

The ATS480 units incorporate many distinct types of line, starter, and load protections, including:

- Phase failure (line)

- Integrated thermal protection (motor)

- Thermal protection (starter)

- Current overload (motor)

- Underload (motor)

- Excessive starting time, locked rotor (motor)

- Motor phase loss (motor)

- Line supply phase loss (line, motor)

- Thermal protection (motor) via a direct connection to a positive temperature coefficient (PTC) thermistor or platinum 100 (PT100) 2 or 3-wire resistance temperature detector (RTD) probe

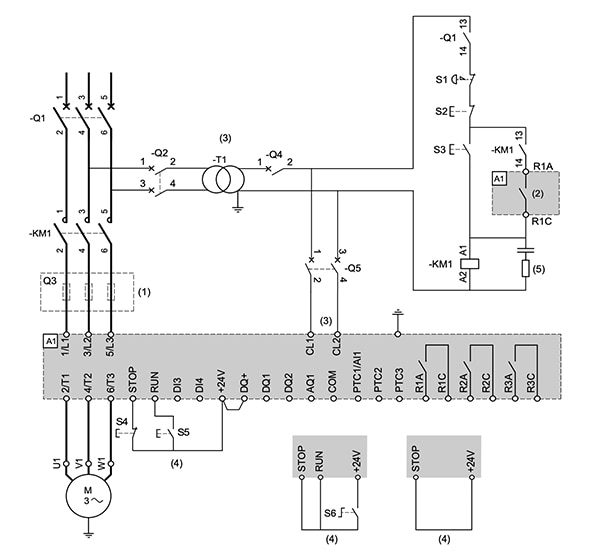

There are many circuit-connection possibilities to meet the diverse needs of the target applications. For example, one basic configuration targets local control where it is desired to require manual intervention to restart after an error reset, even in the case of remote control (Figure 2). Here, the operator presses the S3 pushbutton to restart.

Figure 2: Shown is one of many wiring options for the soft starter; the user needs to manually initiate a restart after an error reset by pressing S3. (Image source: Schneider Electric)

Figure 2: Shown is one of many wiring options for the soft starter; the user needs to manually initiate a restart after an error reset by pressing S3. (Image source: Schneider Electric)

The specifics of the component designations are defined in Table 1.

Table 1: Shown are the component designations for Figure 2. (Image source: Schneider Electric)

Table 1: Shown are the component designations for Figure 2. (Image source: Schneider Electric)

The ATS480 units also feature discrete normally open (NO) and normally closed (NC) electromechanical relay contacts rated to 2 A/250 VAC and 30 volt open-collector digital outputs. These contacts and outputs simplify the implementation of additional features, such as indicator lamps or auxiliary equipment.

Connectivity and cybersecurity

In addition to advanced soft-starter functionality, all ATS480 units support a wide range of connectivity options. Each ATS480 unit has two RJ45 ports for connections to configuration and firmware updates and an external plain text or graphic display terminal. Also, each is equipped with one slot for an additional communication module supporting Modbus TCP, Ethernet/IP, CANopen, PROFINET, or PROFIBUS DP formats.

This connectivity inevitably brings security concerns. To address these, the series has cybersecurity “best practices” embedded in the units to protect against deliberate mischief (hacking) and well-intentioned but careless activities by staff or contractors. These protections incorporate account management, including user authentication and authorization, and multiple layers of password protection. There are also deliberate restrictions on various ports, functions, and sources.

Higher-level security includes in-depth, proactive defenses to manage cybersecurity-related events, including detailed time and user-stamped activity logs. The authenticity of the installed firmware and any upgrades is enhanced by digitally signed firmware and cryptographic keys. This ensures that valid firmware is used on each power-up cycle.

Human-machine interface also accommodated

In addition to extensive connectivity, many soft-start installations also need provision for immediate and direct operator accessibility. This access begins with a basic RUN and STOP initiation via discrete, highly visible, and clearly labeled switches on or near the motor or installation. These are often mandated by regulatory safety standards.

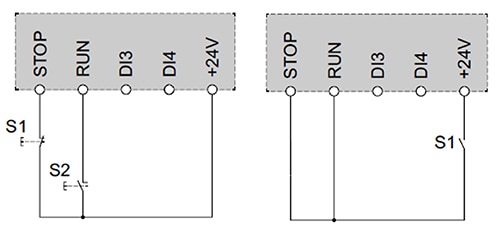

To implement these requirements, the ATS480 units can be wired with two independent run and stop switches or a single run/stop (Figure 3).

Figure 3: The soft starter can be wired to use two independent stop and run pushbuttons or one switch in a dual role. (Image source: Schneider Electric)

Figure 3: The soft starter can be wired to use two independent stop and run pushbuttons or one switch in a dual role. (Image source: Schneider Electric)

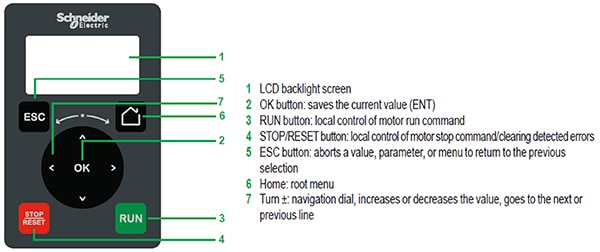

For basic setup, run, and interrogation, designers can use the VW3A1113 eight-line, plain text display terminal (Figure 4). Using the available RJ45 connector, this terminal can be connected and mounted on the front of the soft starter or mounted to an enclosure door using a remote mounting accessory.

Figure 4: The VW3A1113 plain text display terminal connects to the soft starter using the included RJ45 connector and supports basic setup, run, and interrogation functions. (Image source: Schneider Electric)

Figure 4: The VW3A1113 plain text display terminal connects to the soft starter using the included RJ45 connector and supports basic setup, run, and interrogation functions. (Image source: Schneider Electric)

This multilanguage unit (English, French, Spanish, Italian, German, and Chinese, with other languages available via download) requires a password for logging in to ensure system security. Once connected, it can be used to:

- Control, adjust, and configure the soft starter

- Display current values of motor, input/output, and machine data

- Store and download configurations

- Duplicate the configuration of one powered-up soft starter on another that is also powered up

For more advanced diagnostics, control, monitoring, and file management, Schneider’s Device Type Manager (DTM) and SoMove software can be used with a PC-based graphic terminal display arrangement.

Power rating dictates packaging, form factor

Although the units in the Altivar Soft Starter ATS480 family provide the same functions, capabilities, user interfaces, and connectivity, they differ in their drive-power levels. This dictates the appropriate packaging and form factor, which can be easily seen by looking at the series' lowest and highest-power members.

The ATS480D17Y (Figure 5, left) is rated for supplying and controlling three-phase AC motors with a current of 17 A from a 208 to 690 VAC line and operates using a control supply of 110 to 230 VAC. It measures 275 millimeters (mm) high, 160 mm wide, 8 mm deep, and weighs just under 5 kilograms (kg).

Figure 5: The smallest (left) and largest (right) units in the Altivar Soft Starter ATS480 family are functionally similar but encompass a wide span in their current handling and weight specifications. (Image source: Schneider Electric)

Figure 5: The smallest (left) and largest (right) units in the Altivar Soft Starter ATS480 family are functionally similar but encompass a wide span in their current handling and weight specifications. (Image source: Schneider Electric)

In contrast, the ATS480M12Y (Figure 5, right) is rated for a far more powerful 1200 A from a 208 to 690 VAC line and operates using a control supply of 110 to 230 VAC. While it offers features and functions nearly identical to the 17 A unit, it is far larger at 890 mm high, 770 mm wide, and 329 mm deep, with a weight of 115 kg.

Conclusion

Soft starters are an essential link between the multiphase AC line and medium-to-larger three-phase AC motors, where they manage inrush current. The Altivar Soft Starter ATS480 family from Schneider Electric supports motors ranging from 17 A to 1200 A with extensive network connectivity and enhanced cybersecurity. They also provide various functions to improve performance, safety, and reliability.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.