Use CCS Connectors to Simplify the Implementation of Safe EV Fast Charging Systems

Contributed By DigiKey's North American Editors

2022-03-23

The use of electric vehicles (EVs) is growing across a variety of applications, from agriculture and municipalities to consumers, thanks in large part to the ongoing reduction of “range anxiety”. While advanced battery technologies are enabling higher battery capacity per unit volume—and thus longer driving ranges—the utility of such advances is limited if it takes too long to recharge the battery. This has put the onus on automotive companies and their component suppliers to quickly adopt fast-charge methodologies.

One of the critical components in charging are the connectors. They now must be capable of handling up to 500 kilowatts (kW) at up to 1,000 volts DC, while also accommodating AC sources. They must also meet the requirements of IEC 62196 and SAE J1772 standards for safe and intelligent fast charging. To satisfy all of the automotive and non-automotive system demands, designers of BEV systems can turn to connectors that meet the Combined Charging System (CCS) specifications.

This article reviews the basic EV charging levels and modes, and then moves on to the requirements for CCS connectors, including a comparison of CCS type 1, CCS type 2, and Chinese GB/T connectors. It closes by reviewing extended capabilities offered by some suppliers such as wider operating temperature ranges and higher ingress protection (IP) ratings, using examples of CCS connectors from Phoenix Contact, TE Connectivity and Adam Tech.

EV combined charging system

The CSS vehicle inlet is designed to accept both AC and DC power connectors. AC fast charging is beneficial when parked for extended periods in a garage or parking lot, and fast DC charging is used when parked for short periods at stores, rest stops, and dedicated charging stations (Figure 1).

Figure 1: A single CCS vehicle inlet can support both AC and DC fast charging. (Image source: Phoenix Contact)

Figure 1: A single CCS vehicle inlet can support both AC and DC fast charging. (Image source: Phoenix Contact)

EV charging levels and modes

EV charging classifications include; charging levels, charging modes, wiring cases, and in the case of CCS, charging connector types. In the U.S., SAE J1772 recognizes three charging levels:

- Level 1 uses residential 120 VAC power and is limited to about 1.9 kW. Level 1 is slow.

- Level 2 charging uses 208/240 VAC single-phase power. It can supply up to about 19 kW with a 240 VAC source. Level 2 is “fast AC charging” and charges three to seven times faster than Level 1. Levels 1 and 2 power the on-board EV charger.

- Level 3 is DC fast charging and uses an external DC charger to deliver 600 VDC at 400 amperes (A) for a total power of 240 kW. Advanced DC fast chargers can deliver 500 kW (1,000 VDC at 500 A).

In Europe, IEC 61851-1 defines four modes of EV charging:

- Mode 1 charging uses a simple cable plugged directly into an AC outlet. It is low power and infrequently used.

- Mode 2 also plugs directly into an AC outlet but adds integrated protection, called an in-cable control and protection device (IC-CPD). Mode 2 is safer than Mode 1, but only supports charging up to about 15 kW with three-phase power.

Modes 3 and 4 are fast charging:

- Mode 3 uses a dedicated charging station (also called EV supply equipment, or EVSE) to deliver up to 120 kW AC. Modes 1, 2 and 3 all use the EV’s onboard charger to control battery charging.

- Mode 4 refers to fast DC charging. The EV onboard charger is bypassed and the EVSE provides power directly to the battery via a DC connector. Several hundred kW can be delivered with Mode 4. While energy feedback using a high-level communication protocol (HLC) and charging control is possible in Mode 3, it is required in Mode 4.

Connection types, modes, and cases

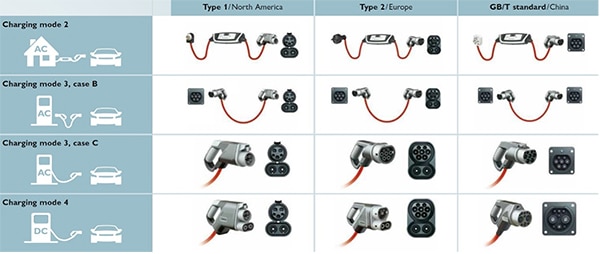

CCS is standardized in SAE J1772 with connector Type 1 in North America, and in IEC 62196 with connector Type 2 in Europe. The HCL interface between the EV and the EVSE is based on ISO/IEC 15118 and DIN SPEC 70121. There are three possible EV-to-power connections; cases A, B, and C.

In case A, the cable is permanently connected to the EV, and is plugged into the power source as needed. Case A is not used in CCS. Cases B and C are used with CCS, and with the corresponding Chinese standard called GB/T (Figure 2). When the power cable is detachable at both ends, it’s case B. If the cable is permanently connected to the EVSE, it’s case C. Charging Mode 3 can use either case B or case C. Charging Mode 4 only uses case C.

Figure 2: Comparison of CCS type 1 (North America), type 2 (Europe), and GB/T (China) connector types, modes, and cases. (Image source: Phoenix Contact)

Figure 2: Comparison of CCS type 1 (North America), type 2 (Europe), and GB/T (China) connector types, modes, and cases. (Image source: Phoenix Contact)

Temperature monitoring and active cooling

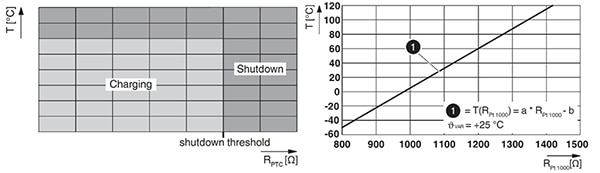

Monitoring contact temperature is important in fast charging systems. According to IEC 62196, the temperature rise at the contacts can’t exceed 50°C. The HCL interface between the EV and the EVSE is used to communicate the temperature data. If the temperature increases too much, the EVSE will slow or stop the charging. In the case of CCS connectors for AC charging, positive temperature coefficient (PTC) thermistors monitor the temperature, as required by DIN 60738. If the connector gets too hot, charging stops (Figure 3). For fast DC charging, DIN 60751 calls for two Pt1000 sensors, one on each contact. A Pt1000 has a resistance that increases linearly with rising temperature.

Figure 3: A PTC temperature sensor shuts down AC charging to keep the temperature from exceeding safe levels (left). For fast DC charging, a Pt1000 sensor enables the temperature to be continuously monitored (right). (Image source: Phoenix Contact)

Figure 3: A PTC temperature sensor shuts down AC charging to keep the temperature from exceeding safe levels (left). For fast DC charging, a Pt1000 sensor enables the temperature to be continuously monitored (right). (Image source: Phoenix Contact)

Temperature monitoring, together with active cooling, is needed in systems that deliver charging currents over 250 A (Figure 4). With an active cooling design, CCS connectors can deliver up to 500 kW (500 A at 1,000 VDC). In the case where the ambient temperature rises unexpectedly or an overload condition develops, temperature monitoring enables the system to increase the cooling rate or decrease the charging rate to maintain the connector contacts temperature rise below the +50°C specification limit.

Figure 4: Active cooling combined with temperature sensing can support full 500 A charging and maintain the connector temperature rise below +50°C. (Image source: Phoenix Contact (modified by author))

Figure 4: Active cooling combined with temperature sensing can support full 500 A charging and maintain the connector temperature rise below +50°C. (Image source: Phoenix Contact (modified by author))

Integrated locking mechanisms

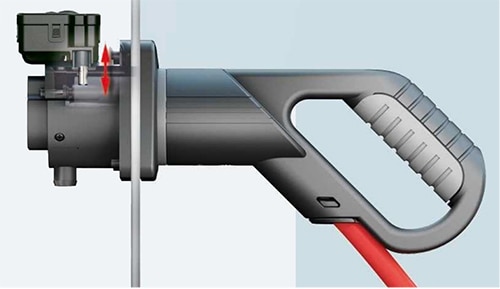

Locking mechanisms are integrated into CCS connector systems. The locking mechanism in Type 1 connectors is a manual clipping mechanism. In Type 2 connectors, locking is accomplished using an electromagnetically activated metal bolt (Figure 5). The lock is controlled and its state is communicated to the EVSE through a separate connection.

Figure 5: CCS vehicle inlets are equipped with an electromechanically controlled locking bolt (next to red arrows, top left) designed to withstand high pull-out forces. (Image source: Phoenix Contact)

Figure 5: CCS vehicle inlets are equipped with an electromechanically controlled locking bolt (next to red arrows, top left) designed to withstand high pull-out forces. (Image source: Phoenix Contact)

Type 1 and 2 inlets and connectors

The CHARX CCS charging inlets from Phoenix Contact have DC cable cross-sections up to 95 square millimeters that can support charging rates up to 500 kW. The model 1194398 can deliver 125 kW of charging under normal operation and up to 250 kW in boost mode (Figure 6). This CCS type 1 inlet is designed for use in charging modes 2, 3, and 4. It includes a PTC chain temperature sensor on the AC contacts and Pt1000 sensors on the DC contacts.

Figure 6: The model 1194398 CCS type 1 vehicle charging inlet for charging with AC or DC power can deliver 125 kW under normal operation, and up to 250 kW in boost mode. (Image source: Phoenix Contact)

Figure 6: The model 1194398 CCS type 1 vehicle charging inlet for charging with AC or DC power can deliver 125 kW under normal operation, and up to 250 kW in boost mode. (Image source: Phoenix Contact)

For higher power needs, the 1162148 vehicle charging inlet from Phoenix Contact supports charging rates of 500 kW in burst mode and 250 kW in normal operation. Digital signal transmission using pulse width modulation (PWM) is implemented with powerline communication according to ISO/IEC 15118 and DIN SPEC 70121. It has an ambient operating temperature range of -40°C to +60°C.

Applications that need a CCS type 1 AC plug for Level 2 charging can use the model 2267220-3 from TE Connectivity AMP Connectors (Figure 7). Rated for 240 VAC and 32 A, this connector features three power and two signal contacts. It has an extended operating temperature range of -55°C to +105°C and is rated for 10,000 mating cycles.

Figure 7: CCS type 1 EV charging connector showing the integrated manual locking system (left side of the connector). (Image source: TE Connectivity)

Figure 7: CCS type 1 EV charging connector showing the integrated manual locking system (left side of the connector). (Image source: TE Connectivity)

Adam Tech’s EV charger cable assemblies include type 1 and type 2 plugs with cable lengths of 3 meters (m) (9.84 feet (ft.)) or 5 m (16.4 ft.), and are available with ingress protection (IP) ratings of IP54 or IP55. For example, the CA #EV03AT-004-5M is a type 2 connector with a 5 m cable and an IP55 rating (Figure 8). It has five power and two signal contacts and is rated for 480 VAC at 16 A with an operating temperature range of -30°C to +50°C.

Figure 8: The CA #EV03AT-004-5M CCS type 2 connectors are rated for 480 VAC at 16 A. (Image source: Adam Tech)

Figure 8: The CA #EV03AT-004-5M CCS type 2 connectors are rated for 480 VAC at 16 A. (Image source: Adam Tech)

CCS specification considerations

The overall mechanical and electrical characteristics of CCS vehicle charging inlets and connectors are standardized, but there are a few areas designers need to be aware of when specifying these devices:

IP ratings: These ratings are specified several ways; when plugged in, when unplugged without a cover, and unplugged with a cover. Some uncovered plugs are rated for IP20, meaning that it’s touch-proof and will be resistant to dust or objects that are over 12 mm in size. However, it has no protection against liquids and will be susceptible to damage if it comes into contact with water sprays. IP54, IP55, and IP65 ratings are common for CCS plugs when covered or when they are plugged in. IP65 has a higher degree of waterproofing compared with IP54 units, but the same degree of waterproofing compared with IP55 units. IP54 and IP55 units have less dust-proofing compared with IP65 units.

Operating temperature range: There is no standard for this specification. Ranges such as -30°C to +50°C and -40°C to +60°C are common, but extended ranges such as -55°C to +105°C are available (see the 2267220-3 from TE Connectivity above).

Temperature measurement components: This is standardized for the AC contacts using PTC devices and on the DC contacts with Pt1000 sensors. Datasheet wording can get confusing here. AC units sometimes call out the use of ‘PTC’ and sometimes ‘PTC chain.’ The correct designation is ‘PTC chain’ since there is a PTC on each contact. If a simple ‘PTC’ is called out in the datasheet, designers should confirm that a ‘PTC chain’ is being used. In the case of the Pt1000 sensor, some datasheets call out a Pt100 sensor which is less sensitive and does not meet the CCS standards. It’s a common error to call a Pt1000 sensor a Pt100 device since the ‘100’ is much more widely used than the ‘1000.’ Designers should confirm it is indeed Pt1000 and that there is one on each contact.

Conclusion

BEV AC and DC fast charging support the growing capacities of EV batteries and the demand for extended driving ranges. AC fast charging is used with EVs that travel relatively short distances. Alternatively, higher power DC fast charging, that can bring an EV battery to 80% of a full charge in a few minutes, supports the needs of long-distance driving. The CCS offers designers a safe, intelligent, and efficient way to combine AC and DC fast charging in automotive and non-automotive applications.

Recommended reading

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.