Use Bidirectional Power Converters and PFC to Improve HEV, BEV, and Electric Grid Efficiency

Contributed By DigiKey's North American Editors

2020-09-29

Designers of power systems for hybrid electric vehicles (HEVs) and battery electric vehicles (BEVs) are under constant pressure to improve efficiency and reliability while lowering cost. While the move to dual 12 volt and 48 volt power rails has helped improve efficiency by reducing chassis wiring weight, designers need dedicated solutions to better manage the two power sources so they can better support each other while also allowing the vehicle to support two-way vehicle-to-grid (V2G) applications.

This need has led to the development of bidirectional converters and bidirectional power factor correction (PFC) systems that allow designers to optimize overall performance of a dual 12 volt/48 volt electric vehicle (EV) design and also connect to the grid for two-way power flow.

This article defines and reviews the benefits of bidirectional power conversion in automotive systems and associated standards. It then introduces solutions from vendors such as Texas Instruments, Analog Devices, and Infineon Technologies and shows how they can be used to implement bidirectional power converters.

What is bidirectional power conversion?

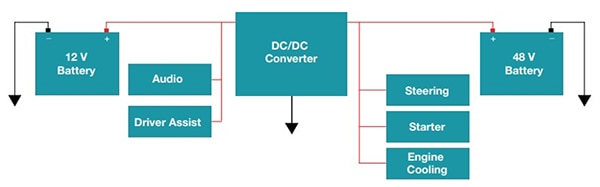

In an HEV with a dual-voltage 12 volt/48 volt architecture, a bidirectional power supply links the 12 volt and 48 volt systems so that either battery can be recharged by the other. It also allows each battery to provide extra power for either voltage rail in the case of an overload condition (Figure 1). As a result, designers can use smaller batteries for each, resulting in higher reliability, greater efficiency, and lower cost.

Figure 1: A bidirectional power supply at the heart of a dual-voltage architecture links the 12 volt and 48 volt systems so that each battery can be recharged by the other and provide extra power in the case of an overload condition. (Image source: Texas Instruments)

Figure 1: A bidirectional power supply at the heart of a dual-voltage architecture links the 12 volt and 48 volt systems so that each battery can be recharged by the other and provide extra power in the case of an overload condition. (Image source: Texas Instruments)

In BEVs, designers can use bidirectional PFC to support bidirectional battery charging, as well as V2G operation. A V2G system supports higher efficiency in several ways:

- It can return energy to the grid during periods of high demand

- It can reduce the charge rate on the batteries as necessary to help balance the load on the grid

- It allows the vehicle to be used to store energy from renewable energy sources

While dual voltage systems in HEVs are self-contained within the vehicle and enhance fuel economy, the bidirectional charger in a V2G system is designed to bring broader cost benefits beyond improvements in fuel economy and must interface with the outside world.

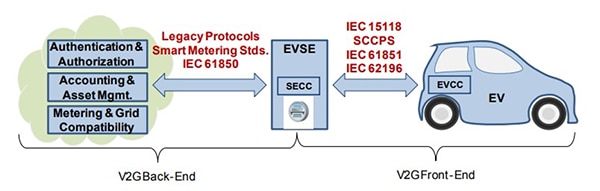

Implementation of V2G requires communication technologies and algorithms to sense grid status, as well as the ability to interface with electric vehicle charging infrastructure (Figure 2).

Figure 2: In addition to bidirectional power conversion, V2G systems need to include various interconnect and communications standards. (Image source: Honda)

Figure 2: In addition to bidirectional power conversion, V2G systems need to include various interconnect and communications standards. (Image source: Honda)

The resulting V2G infrastructure brings economic benefits including the ability to provide power to the grid during periods of peak demand (potentially generating income for the vehicle owner) and recharging vehicle batteries during periods of low demand for electricity (reducing vehicle charging costs).

Standards related to bidirectional power conversion

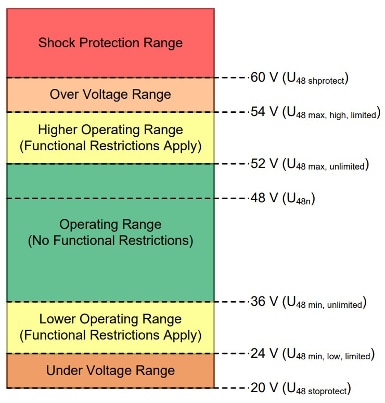

The LV148/VDA320 specifications define the electrical requirements and test conditions for combining a 48 volt bus and a 12 volt bus in dual-voltage automotive systems (Figure 3). LV148 has been adopted by German automakers Audi, BMW, Daimler, Porsche, and Volkswagen, and it applies to conventional internal combustion vehicles as well as HEVs. At the time of this writing, the ISO 21780 standard for “Road vehicles — Supply voltage of 48 V — Electrical requirements and tests” is under development.

Figure 3: LV148/VDA320 specifications define the electrical requirements and test conditions for combining a 48 volt bus and a 12 volt bus in dual-voltage automotive systems; shown is the spec for a 48 volt bus. (Image source: Texas Instruments)

Figure 3: LV148/VDA320 specifications define the electrical requirements and test conditions for combining a 48 volt bus and a 12 volt bus in dual-voltage automotive systems; shown is the spec for a 48 volt bus. (Image source: Texas Instruments)

There are several communication protocols that can apply to V2G systems including:

- ISO/IEC 15118: Defines a V2G communication interface for bidirectional charging/discharging of electric vehicles. It uses the IEEE P1901.2 HomePlug Green PHY (HPGP) broadband Power Line Communication (PLC) specification as the best protocol to ensure robust communication and a high data rate. Operating at frequencies between 2 MHz and 30 MHz, HPGP enables the system to distinguish valid data on a connected line against noise from other nearby sources.

- IEC 61850: Defines communication protocols for intelligent electronic devices at electrical substations that can help manage energy flow between renewable electricity resources and electric vehicle supply equipment (EVSE), such as chargers.

Figure 4: IEC 61850 defines power and data flows for V2G systems and uses the IEEE P1901.2 HPGP PLC specification to ensure robust communication and a high data rate. (Image source: IBIS)

Figure 4: IEC 61850 defines power and data flows for V2G systems and uses the IEEE P1901.2 HPGP PLC specification to ensure robust communication and a high data rate. (Image source: IBIS)

Bidirectional multiphase DC-DC converters for 12 volt/48 volt systems

The high power level of a typical 12 volt/48 volt bidirectional DC-DC converter usually results in the use of a multiphase topology. A multiphase design improves overall conversion efficiency by enabling phase dropping, reducing the number of active phases as the demand for power decreases. Multiphase designs also enable the use of smaller filter components on the outputs of each phase; the use of smaller inductors improves load transient performance. Finally, operating the phases with the appropriate interleaving results in lower output ripple.

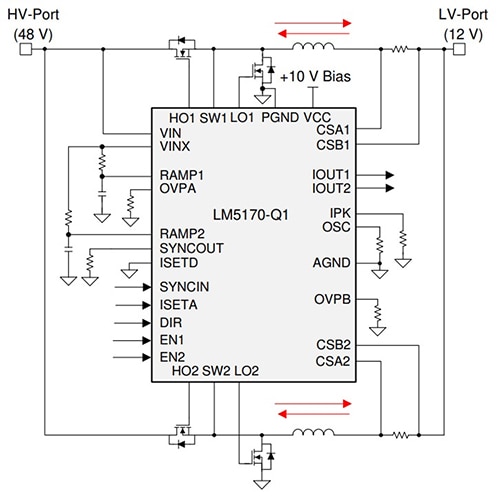

The LM5170-Q1 from Texas Instruments is a high performance, multiphase bidirectional current controller intended to manage current transfer between the 48 volt section and the 12 volt section of automotive dual-battery systems (Figure 5). It integrates essential analog functions that enable the design of high power converters with a minimal number of external components. Multiphase parallel operation is achieved by connecting two LM5170-Q1 controllers for three or four phase operation, or by synchronizing multiple controllers to phase shifted clocks for a higher number of phases.

Figure 5: The LM5170-Q1 multiphase bidirectional current controller manages current transfer between the 48 volt and 12 volt sections of an automotive dual-battery system; the red arrows highlight the bidirectional current flow. (Image source: Texas Instruments)

Figure 5: The LM5170-Q1 multiphase bidirectional current controller manages current transfer between the 48 volt and 12 volt sections of an automotive dual-battery system; the red arrows highlight the bidirectional current flow. (Image source: Texas Instruments)

The LM5170-Q1 includes dual-channel differential current sense amplifiers and dedicated channel current monitors to achieve typical current accuracy of 1%. Robust 5 ampere (A) half-bridge gate drivers are capable of driving parallel MOSFET switches delivering 500 watts or more per channel. The diode emulation mode of the synchronous rectifiers prevents negative currents, but also enables discontinuous mode operation for improved efficiency with light loads. Versatile protection features include cycle-by-cycle current limiting, overvoltage protection at both high voltage and low voltage ports, MOSFET failure detection, and overtemperature protection. This controller is automotive functional safety capable.

Texas Instruments offers the LM5170EVM-BIDIR evaluation module so engineers can evaluate the LM5170-Q1 in 12 volt/48 volt dual-battery system applications. The two phases operate in 180˚ interleaved operation, and they evenly share a maximum DC current up to 60 A. This evaluation module also includes various jumpers to flexibly and conveniently configure the circuit to fit for many different use cases, including the capability of being controlled by a microcontroller (MCU) and high-power unidirectional buck or boost converters.

Master/slave multiphase architecture for bidirectional converters

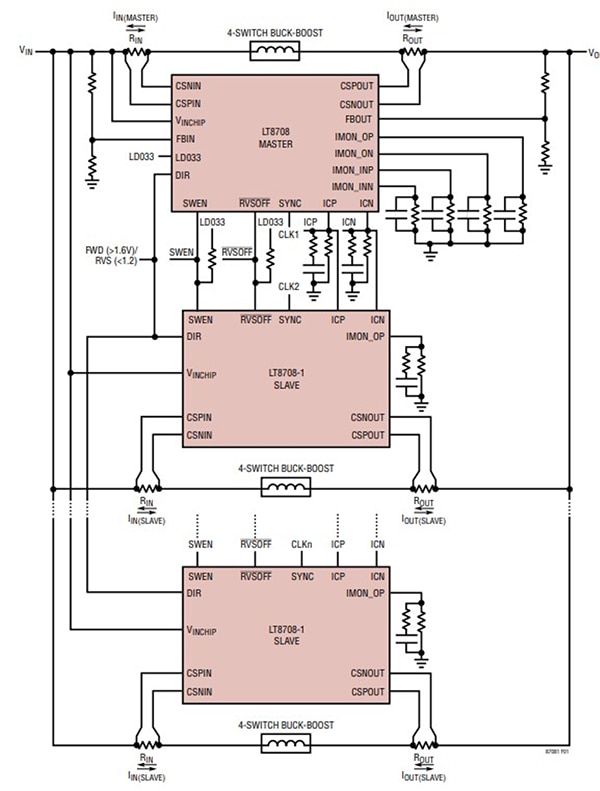

Analog Devices offers the LT8708 buck-boost switching regulator controller for use in 12 volt/48 volt bidirectional power converters. The LT8708 is an 80 volt synchronous 4-switch buck-boost DC-DC controller with bidirectional capability that can support load currents up to about 30 A. For higher current needs, the LT8708 master controller can be combined with one or more slave chips. The use of a master/slave architecture can reduce solution costs in multiphase designs since a single (more expensive) master IC can control multiple (lower cost) slave ICs.

As slaves are connected to the master, they proportionally increase the power and current capability of the system. However, it’s important that the slave have the same conduction modes as the LT8708 so it can conduct current and power in the same direction as the master. The master controls the overall current and voltage limits for an LT8708 multiphase system, and the slaves comply with these limits.

A slave can be easily paralleled with the LT8708 by connecting four signals together (Figure 6). Two additional current limits (forward VIN current and reverse VIN current) are available on each slave that can be set independently.

Figure 6: A three-phase DC-DC converter using the LT8708 (master) and slave ICs highlights the four signal interconnections. (Image source: Analog Devices)

Figure 6: A three-phase DC-DC converter using the LT8708 (master) and slave ICs highlights the four signal interconnections. (Image source: Analog Devices)

The DC2719A demo board from Analog Devices uses an LT8708 combined with an associated slave (LT8708-1) to deliver 40 A of current. The board can operate in both forward and reverse mode. The controller has integrated input voltage and output voltage regulators, and two sets of input and output current regulators that control current flow in forward or reverse direction. Features are included that simplify bidirectional power conversion in battery/capacitor backup systems and other applications that may need regulation of VIN, VOUT, IIN and/or IOUT.

Bidirectional power factor correction for grid interactive BEVs

For designers of grid interactive BEVs, Infineon offers the EVAL3K3WTPPFCSICTOBO1 evaluation board, a 3300 W bridgeless totem-pole power factor corrector with bidirectional power capability (Figure 7). This bridgeless totem-pole PFC board is intended for applications that require high efficiency (about 99%) and high power density (72 watts per cubic inch).

Figure 7: The EVAL3K3WTPPFCSICTOBO1 is a 3300 W bridgeless totem-pole PFC board. (Image source: Infineon)

Figure 7: The EVAL3K3WTPPFCSICTOBO1 is a 3300 W bridgeless totem-pole PFC board. (Image source: Infineon)

The totem-pole topology in PFC applications with continuous conduction mode (CCM) operation is made feasible by using wide bandgap semiconductors. In this case, the Infineon IMZA65R048M1 CoolSiC MOSFET in a TO-247 four-pin package is used to push the efficiency to 99% at half load. The converter operates exclusively at a high line voltage (176 volts rms minimum, 230 volts rms nominal) in CCM with a 65 kilohertz (kHz) switching frequency.

This 3300 W bridgeless bi-directional (PFC/AC-DC and inverter/AC-DC) totem pole is a system solution developed with Infineon power semiconductors, as well as Infineon drivers and controllers. The Infineon devices used in the design include:

- 64 milliohm (mΩ) 650 volt CoolSiC MOSFET (IMZA65R048M1) in a TO-247 four-pin package as totem-pole PFC high frequency switches

- 17 mΩ 600 volt CoolMOS C7 MOSFET (IPW60R017C7) in a TO-247 package for the totem-pole PFC return path (low-frequency bridge)

- 2EDF7275F isolated gate drivers (EiceDRIVER)

- ICE5QSAG QR flyback controller and 950 volt CoolMOS P7 MOSFET (IPU95R3K7P7AKMA1) for the bias auxiliary supply

- XMC1404Q048X0200AAXUMA1 Infineon microcontroller for PFC control implementation

The totem pole implemented in the EVAL3K3WTPPFCSICTOBO1 board operates in CCM in both rectifier (PFC) and inverter mode, with full digital control implementation using the Infineon XMC1404Q048X0200AAXUMA1 microcontroller.

Conclusion

With designers looking to improve efficiency, dual-voltage 12 volt/48 volt architectures have emerged as the topology of choice for HEVs and BEVs. This has created a need for efficient power management to optimize their use. Bidirectional DC-DC converters and battery chargers have emerged to allow 12 volt and 48 volt systems to support each other in cases where one needs to be recharged, or in the case of an overload condition.

Also, in the case of BEVs, a bidirectional PFC stage supports bidirectional power flow between the battery and the utility grid. The resulting V2G connection brings economic benefits beyond improvements in fuel economy including the ability to provide power to the grid during periods of peak demand, and recharging vehicle batteries during periods of low demand for electricity.

Recommended Reading

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.