Use Advanced Battery Monitors, Cell Balancing, and I/O Isolation to Design a Rugged BMS Core

Contributed By DigiKey's North American Editors

2025-07-29

Rechargeable batteries are foundational elements of a battery energy storage system (BESS), with various chemistries increasingly being combined into and used in packs of tens, hundreds, and even thousands of cells to provide more efficient operation at higher voltages. For designers of a battery management system (BMS), this arrangement presents several challenges to achieve optimal performance, efficiency, reliability, and safety.

For example, designing or selecting the integrated circuits (ICs) necessary to meet the needs of this application requires a deep understanding of battery chemistries, charging, monitoring, load balancing, isolation, security, and communication techniques for effective implementation.

To help address these challenges, vendors have integrated many of the necessary functions into largely processor-independent, specialized ICs. Many of these ICs support different lithium-based battery chemistries as well as non-lithium cells. They collect battery cell data and make optimal real-time battery management decisions and actions. They also provide data to the system processor about cell status and state.

This article provides a brief review of the unique requirements of multicell battery packs. It then introduces sophisticated, application-specific, optimized ICs from Analog Devices and describes how they can be used to meet these requirements.

High cell-count packs bring additional challenges

The basic wiring diagram of a battery pack, comprising numerous cells placed in series for higher voltage and in parallel for greater current, is deceptively simple. It implies that the arrangement is merely an extension of a pack of one or a few cells requiring little management. These high-count packs are used in applications such as power tools that require 18 V or 48 V, electric vehicles (EVs) that require 400 V or 800 V, and BESSs that usually require 1,500 V.

The reality of these larger battery packs is that they have subtleties and complexities far beyond what appears on their schematic diagram. The management challenge increases exponentially with the number of cells and packs.

First, the individual cells must be monitored for terminal voltage, charge/discharge profile, state of charge (SoC), temperature, and indications of impending failure. Additionally, the various cells must be managed collectively, with their differences noted and accounted for.

The lack of a universal set of rules further complicates the management of battery cells. The appropriate strategy is also a function of cell chemistry. It differs between major chemistries, such as lithium-ion (Li-ion) and lead-acid, for example, as well as within a given broad chemistry, such as the various Li-ion formulations. Therefore, a high-level BMS strategy must be tailored to the cell chemistry it manages.

Due to the large number of cells in higher-voltage, higher-capacity battery packs and the numerous safety mandates these packs must meet, local cell monitoring and management are the most viable engineering solution. While there is generally a host processor for the system, it typically can only provide higher-level supervisory guidelines to the local cell oversight and assess the aggregate performance of the battery pack. Individual battery-cell monitoring and management are done by autonomous electronics that provide real-time functionality and operate largely without the intervention of a system-level processor.

Passive versus active cell balancing

Cell balancing is critical to maintaining the integrity of a multicell pack and assuring that some cells are not overstressed while others are underutilized. It prevents damage to battery cells and packs, maximizing performance. Balancing ensures that all cells within a pack reach their full capacity simultaneously, preventing overcharging, uneven SoC, excessive discharging, and premature degradation, thereby ultimately extending the battery's lifespan.

There are two approaches to balancing: active and passive. Active balancing is more accurate and faster than passive balancing, but it is more complicated to implement. It uses active circuitry to redistribute charge among the cells in a battery pack, ensuring that they all have the same SoC. This circuitry monitors the voltage of each cell and adjusts the charging and discharging current accordingly.

In contrast, passive balancing relies on Ohm’s Law and balance resistors to bring cells to the same SoC. In addition to being less accurate and slower than active balancing, passive balancing dissipates (wastes) excess energy from a higher-charged cell.

Begin with multicell monitoring

While there are many ESS solutions readily available, two essential “close to the action” functions of a BMS are the monitoring and balancing of individual cells. An IC such as the ADES1830CCSZ (Figure 1), a 16-channel, multicell, multi-chemistry battery monitor, addresses these functions and adds many critical features that support and simplify overall system design and operation.

Figure 1: The multicell, multi-chemistry ADES1830CCSZ battery cell monitor serves as a foundational building block for a comprehensive BMS. (Image source: Analog Devices)

Figure 1: The multicell, multi-chemistry ADES1830CCSZ battery cell monitor serves as a foundational building block for a comprehensive BMS. (Image source: Analog Devices)

This multicell battery-stack monitor measures up to 16 series-connected battery cells with a lifetime total measurement error (TME) of less than 2 mV over the full temperature range; the otherwise identical ADES1831CCSZ has a slightly greater TME of 5 mV. The measurement input range of -2 V to 5.5 V makes both the ADES1830 and ADES1831 suitable for most battery chemistries.

To support consistency when monitoring packs with a large number of cells, all cells can be measured simultaneously and redundantly with dual integral analog-to-digital converters (ADCs). These ADCs operate continuously at a high sampling rate of 4.096 megasamples per second (MSPS), which enables reduced external analog filtering and alias-free measurement results. If needed, additional noise reduction can be achieved by follow-on programmable infinite impulse response (IIR) filters. The ADES1830 and ADES1831 also feature passive balancing using individual pulse width modulation (PWM) duty-cycle control and support up to 300 milliamperes (mA) of discharge current for each cell.

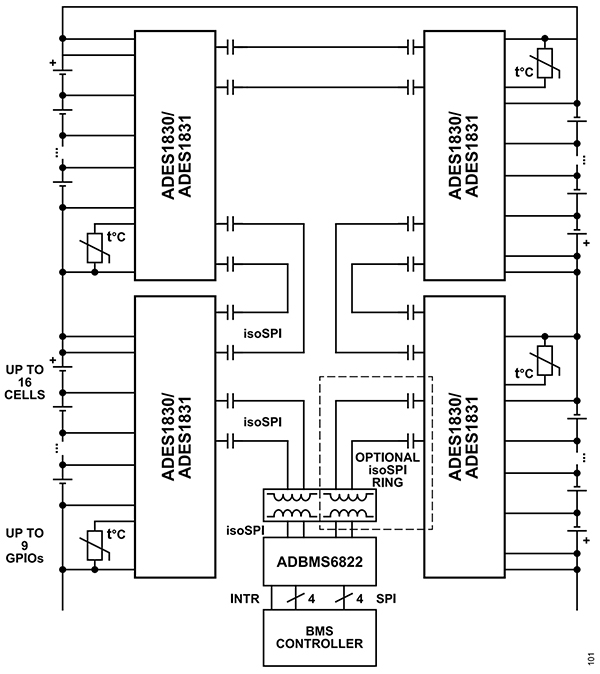

Although a single ADES1830 or ADES1831 device supports just 16 cells connected in series, multiple devices can be concatenated to monitor cells comprising long, high-voltage battery strings simultaneously. To facilitate this inter-IC connectivity, each device has an isolated serial port interface (isoSPI) for high-speed, RF-immune, long-distance communications, with isolation provided by user-selected capacitors or transformers.

In this way, a single host processor connection can read data and supervise the entire string. This serial-port link can be operated bidirectionally, thus ensuring its integrity even in the event of a fault along the communication path.

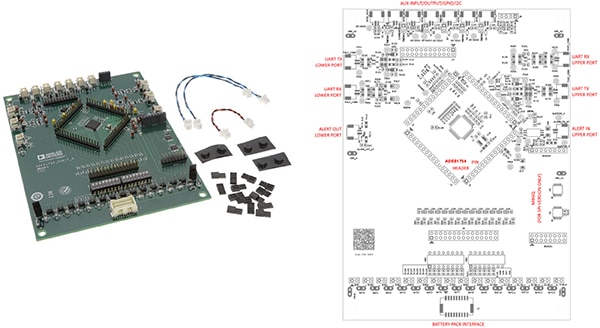

To optimize the applicability of these multicell monitors, Analog Devices offers the EV-ADES1830CCSZ evaluation board (Figure 2, left). For additional realism, multiple evaluation boards can be linked through the isoSPI interface to monitor a long series of cells in a stack (Figure 2, right).

Figure 2: The EV-ADES1830CCSZ evaluation board for the ADES1830 and ADES1831 (left) includes multichannel inputs for cell-voltage readings, cell-balancing circuitry, and isoSPI port connectivity (right). (Image source: Analog Devices)

Figure 2: The EV-ADES1830CCSZ evaluation board for the ADES1830 and ADES1831 (left) includes multichannel inputs for cell-voltage readings, cell-balancing circuitry, and isoSPI port connectivity (right). (Image source: Analog Devices)

Enhanced cell balancing for optimum performance

Optimizing the performance of larger multicell packs requires enhanced cell balancing. To address this challenge, Analog Devices offers the ADES1754GCB/V+ (Figure 3), a 14-channel, high-voltage, multi-chemistry battery-balancing IC data acquisition system designed for managing both high- and low-voltage battery modules.

Figure 3: The ADES1754GCB/V+ 14-channel, high-voltage multi-chemistry data acquisition IC supports advanced battery-balancing techniques. (Image source: Analog Devices)

Figure 3: The ADES1754GCB/V+ 14-channel, high-voltage multi-chemistry data acquisition IC supports advanced battery-balancing techniques. (Image source: Analog Devices)

This system can measure 14 cell voltages and a combination of six temperatures with fully redundant measurement engines in 162 microseconds (μs). Alternatively, it can assess all inputs solely with the ADC measurement engine in 99 μs.

For active cell balancing, there are 14 internal-balancing switches rated for over 300 mA of cell-balancing current, which can be switched to support extensive built-in diagnostics. Using these switches, the IC can be configured to implement automated balancing with individual cell timers or by cell voltage. The IC also provides an emergency discharge mode.

Up to 32 of these devices can be daisy-chained to manage up to 448 cells and monitor 192 temperatures. Cell and bus-bar voltages ranging from -2.5 V to 5 V are measured differentially over a 65 V common-mode range, with a typical accuracy of 100 μV. For robust communication, the system uses Analog Devices' battery-management UART protocol and supports an I²C controller interface for managing external devices.

As with the ADES1830 and ADES1831, Analog Devices offers the ADES1754EVKIT# (Figure 4, left) evaluation board to improve the design-in experience and reduce the setup period. The board’s physical layout (Figure 4, right) is optimized for efficient connection to multiple battery cells as well as isolated processor I/O.

Figure 4: The ADES1754EVKIT# (left) accelerates the design-in process for the ADES1754; its physical layout (right) is optimized for efficient connection to multiple battery cells as well as isolated processor I/O. (Image source: Analog Devices)

Figure 4: The ADES1754EVKIT# (left) accelerates the design-in process for the ADES1754; its physical layout (right) is optimized for efficient connection to multiple battery cells as well as isolated processor I/O. (Image source: Analog Devices)

The kit provides a convenient platform for evaluating the features and functions of the IC, as well as its electrical parameters. The vertical communication connectors of the kit, along with its snap-and-lock battery pack connector, enable users to quickly build and evaluate a system with up to 32 daisy-chained devices.

Communication and safety isolation complete the BMS core

Due to the obvious safety concerns associated with high battery-pack voltages, it is mandated that the communication link between the BMS controller and the individual battery-monitoring devices include galvanic (ohmic) isolation. Some measurement and monitoring ICs offer direct provision for this isolation, but many do not.

To implement this requirement for cases where it is not an integral part of the circuitry, Analog Devices offers the single-channel ADBMS6821 (Figure 5, left) and dual-channel ADBMS6822. These drop-in compatible, AEC-Q100-qualified ICs implement bidirectional isoSPI communications, thus isolating devices using a single twisted-pair connection for each data link (Figure 5, right).

Figure 5: The single-channel ADBMS6821 (left) and dual-channel ADBMS6822 contain the necessary functional blocks to provide bidirectional isoSPI communications; they interface easily with a bidirectional loop on twisted-pair cables (right). (Image source: Analog Devices)

Figure 5: The single-channel ADBMS6821 (left) and dual-channel ADBMS6822 contain the necessary functional blocks to provide bidirectional isoSPI communications; they interface easily with a bidirectional loop on twisted-pair cables (right). (Image source: Analog Devices)

In operation, each transceiver encodes logic states into signals that are transmitted across the isolation barrier to another transceiver. The receiving device decodes the transmission and drives the peripheral bus to the appropriate logic states.

The transceiver acts as a bridge between the BMS microcontroller SPI port and the isoSPI ports of individual battery-pack monitors. It translates standard SPI signals (CS, SCK, PICO, and POCI) into pulses that can be sent bidirectionally on twisted-pair cables.

The devices support data rates of 2 megabits per second (Mbits/s) and cable lengths of 100 meters (m) with very low electromagnetic interference (EMI) susceptibility and emissions. Designers can choose to use either capacitors or transformers for the isolation barrier, depending on the required voltage rating, available space, regulatory issues, and other technical factors.

As a further benefit, the transceivers can be paired with other advanced ADBMS-family stack-monitor solutions from Analog Devices to enable cell voltage and sensor monitoring even while the BMS controller is powered down, resulting in a low-power cell-monitoring (LPCM) design.

As with other BMS devices, an evaluation board is a valuable adjunct for designers to explore, exercise, and verify functionality. For these transceivers, a full-featured evaluation board, the EVAL-ADBMS6822DEC (Figure 6), is available. It functions as a dual SPI-to-2-wire isoSPI adapter, featuring the dual-channel ADBMS6822, but can also be used with the single-channel ADBMS6821.

Figure 6: As a dual SPI-to-2-wire isoSPI adapter, the EVAL-ADBMS6822DEC facilitates the development and evaluation of an isolated link between the BMS processor and individual cell-monitoring devices. (Image source: Analog Devices)

Figure 6: As a dual SPI-to-2-wire isoSPI adapter, the EVAL-ADBMS6822DEC facilitates the development and evaluation of an isolated link between the BMS processor and individual cell-monitoring devices. (Image source: Analog Devices)

Using this evaluation board, multiple ADBMS68xx battery monitors can be linked through daisy-chain interconnections. The board also features a reversible isoSPI port, which enables a redundant communication path to the peripheral units. The printed circuit board (pc board), components, and connectors are optimized for low EMI susceptibility and emissions.

Conclusion

Proper, effective, and efficient management of battery packs with a large number of battery cells and corresponding high voltages is a complex matter with many design subtleties. Optimized, application-specific ICs from Analog Devices offer a variety of solutions for meeting the required technical and regulatory requirements.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.