Understanding Supercapacitors and Their Relationship with Batteries

Contributed By DigiKey's North American Editors

2024-05-14

The need for reliable energy storage sources has grown dramatically through the rise of the Internet of Things (IoT), the Industrial IoT (IIoT), portable electronics, and larger applications such as industrial plants and data centers. Batteries provide direct power for smaller devices, while batteries in larger applications are frequently used for backup in case of a primary power outage.

Small devices frequently rely on lithium-ion (Li-ion) or alkaline coin cell batteries to achieve the goals of small form factors and minimal maintenance. Li-ion cells require careful attention to charging cycle limits and safety. Batteries used for backup can wear out quickly after rapid recharge and must be replaced. These batteries also require complex battery management systems and still have the potential for thermal runaway, which leads to safety concerns.

Electric double-layer capacitors (EDLC), or supercapacitors, offer a complementary technology to batteries. Where batteries can supply power for relatively long periods, supercapacitors can quickly provide power for short periods. Supercapacitors are also environmentally friendly, not subject to thermal runaway, and can operate reliably for up to 20 years. They can be used as the sole energy storage method, in combination with batteries, or as a hybrid device to optimize power delivery.

This article briefly describes supercapacitors relative to batteries. It then reviews some typical applications, standalone and in combination with batteries. Supercapacitors from Eaton are used for illustrative purposes.

Supercapacitor and battery differences

A supercapacitor is an energy storage device with unusually high specific power capacity compared to electrochemical storage devices like batteries. Batteries and supercapacitors perform similar functions in supplying power but operate differently. A supercapacitor operates like a classic capacitor in that the discharge profile for a constant discharge current exhibits a linear decrease in voltage. Unlike a battery, the energy storage in a supercapacitor is electrostatic, so there are no chemical changes in the device, and charge and discharge operations are almost entirely reversible. This means that it can tolerate a larger number of charge-discharge cycles.

Batteries store energy electrochemically. Li-ion batteries' discharge profile is flat; they exhibit a nearly constant voltage characteristic until the battery is almost fully discharged. Due to the degradation of the chemical mechanisms, the number of charge-discharge cycles in a Li-ion battery is limited. Factors such as temperature, charging voltage, and the depth of discharge influence battery capacity reduction.

Li-ion batteries are subject to thermal runaway, self-ignition, and even explosion. Heat generation is unavoidable due to chemical reactions during charge and discharge from resistive heating. For this reason, batteries require temperature monitoring to ensure user safety.

Comparing supercapacitor and Li-ion battery specifications

Batteries provide high energy density. Supercapacitors have lower energy density than batteries, but high power density because they can be discharged almost instantaneously. The electrochemical processes in a battery take more time to deliver energy to a load. Both devices have features that fit specific energy storage needs (Figure 1).

Figure 1: Shown is a comparison of the features of supercapacitors and Li-ion batteries. (Image source: Eaton)

Figure 1: Shown is a comparison of the features of supercapacitors and Li-ion batteries. (Image source: Eaton)

Comparing the energy density, in watt hours per liter (Wh/L), and the power density, in watts per liter (W/L), shows the most significant difference between the devices. This also affects the discharge times; supercapacitors are intended to supply energy over brief intervals (transient events), whereas batteries deal with lengthy events. The supercapacitor discharges in seconds or minutes, while a battery can deliver energy for hours. This characteristic affects their application.

Supercapacitors support a wider operating temperature range than batteries. Their nearly lossless electrostatic processes also contribute to their greater efficiency and faster charging rates.

Supercapacitor examples

Eaton offers a complete line of reliable supercapacitors for energy storage applications requiring high power density and fast charging. Its supercapacitors' physical packaging sometimes matches that of batteries, especially coin cells. They are also available in conventional capacitor cylindrical packages (Figure 2).

Figure 2: Supercapacitors are available in standard cylindrical capacitor packages with radial leads; some are packaged to match Li-ion battery coin cell formats. (Image source: Eaton)

Figure 2: Supercapacitors are available in standard cylindrical capacitor packages with radial leads; some are packaged to match Li-ion battery coin cell formats. (Image source: Eaton)

The Eaton TV1030-3R0106-R shown in Figure 2 (left) is a 10 Farad (F) supercapacitor with a maximum working voltage of 3 V. It is packaged in a cylindrical can with radial leads. The can has a diameter of 10.5 millimeters (mm) (0.413 inches (in.)) and a height of 31.5 mm (1.24 in.). It has an operating temperature range of -25°C to +65°C and an extended operating range of -25°C to +85°C when derated to operate at or below 2.5 V. It can store 12.5 milliwatt-hours (mW/hr) of energy and output a peak power of 86.5 W. It is rated for 500,000 charge/discharge cycles.

Supercapacitors may replace coin cell batteries in many applications, such as memory backup power. The Eaton KVR-5R0C155-R (Figure 2, right) is a 1.5 F supercapacitor rated at a maximum working voltage of 5 volts. Its package dimensions are similar to those of a 20 mm coin cell. It can deliver a peak power of 0.208 watts. Its operating temperature range is -25°C to +70°C. It is also rated for 500,000 charge/discharge cycles.

Increasing supercapacitor energy density

The energy stored in a supercapacitor is proportional to its capacitance and the square of the voltage to which it is charged. Thus, the energy density can be increased by increasing the number of cells, connecting them in parallel. Higher energy densities can be achieved by creating supercapacitor modules with high capacitance and higher working voltages (Figure 3).

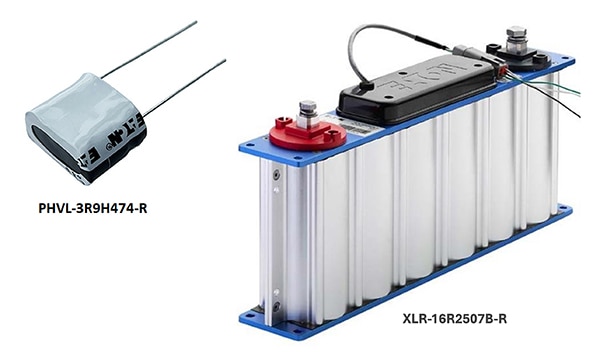

Figure 3: The energy density of a supercapacitor can be increased by adding multiple cells and increasing the working voltage. (Image source: Eaton)

Figure 3: The energy density of a supercapacitor can be increased by adding multiple cells and increasing the working voltage. (Image source: Eaton)

The Eaton PHVL-3R9H474-R supercapacitor (Figure 3, left), is a 470 millifarad (mF), 3.9 volt device with dual cells. It has a very low effective series resistance (ESR) of 0.4 ohms (Ω) to reduce conductive losses, and it can deliver a peak power of 9.5 W. It has an operating temperature range of -40°C to +65°C. Like the previously discussed supercapacitors, it is rated for 500,000 charge/discharge cycles. The physical package is 14.5 mm (0.571 in.) high, 17.3 mm (0.681 in.) long, and 9 mm (0.354 in.) wide.

Modular supercapacitor packages can supply significant amounts of backup energy. The Eaton XLR-16R2507B-R (Figure 3, right) has a capacitance of 500 F and operates with a maximum voltage of 16.2 V. The module has an ESR of 1.7 milliohms (mΩ) and can supply a peak power of 38.6 kilowatts (kW). The operating temperature range is -40°C to +65°C (cell temperature). The package is 177 mm (6.97 in.) high, 417 mm (16.417 in.) long, and 68 mm (2.677 in.) wide.

Hybrid supercapacitors

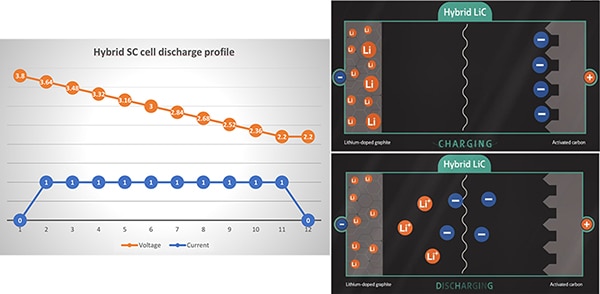

Efforts to blend the characteristics of supercapacitors and Li-ion batteries have resulted in a hybrid supercapacitor called the Li-ion capacitor (LiC). This increases the supercapacitor's energy density while still offering faster response times than a battery. The LiC has an asymmetrical structure using a lithium-doped graphite anode and an activated charcoal cathode (Figure 4).

Figure 4: The hybrid supercapacitor embodies the supercapacitor and Li-ion battery characteristics. It has an enhanced number of charge/discharge cycles compared to a battery and higher discharge rates. (Image source: Eaton)

Figure 4: The hybrid supercapacitor embodies the supercapacitor and Li-ion battery characteristics. It has an enhanced number of charge/discharge cycles compared to a battery and higher discharge rates. (Image source: Eaton)

The structure of the hybrid supercapacitor merges the electrochemical nature of the lithium battery with the electrostatic properties of the supercapacitor to provide a noticeable benefit to designers. The charge movement is an electrochemical process in the LiC, but it is done with a lesser depth than in a battery, resulting in an enhanced number of charge/discharge cycles and higher discharge rates. The resulting discharge profile is very similar to the supercapacitor.

For example, the HS1016-3R8306-R is a 30 F, 3.8 V, hybrid supercapacitor housed in a cylindrical package with radial leads. It has an ESR of 0.55 Ω and can supply a peak power of 6.6 W. Its operating temperature range is -15°C to +70°C, and it has an extended operating range of -15°C to +85°C, derated to operate at or under 3.5 V. It has a rated lifetime of 1,000 hours at rated voltage and maximum operating temperature. The package dimensions are 18 mm (0.709 in.) high and 10.5 mm (0.413 in.) in diameter. Like the supercapacitor, it is rated for 500,000 charge/discharge cycles.

Energy and power density plots

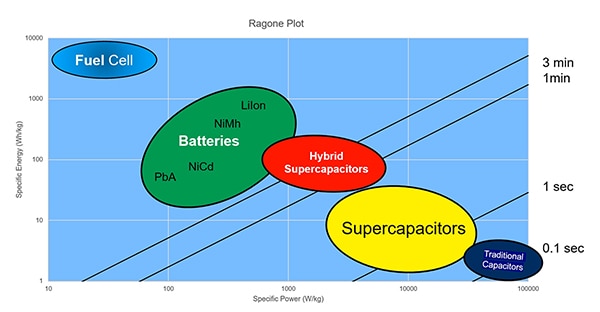

The energy and power density distributions of energy storage devices offer considerable insight into their usefulness and effective operational duration (Figure 5).

Figure 5: A cross plot of energy density vs. power density of battery and supercapacitor devices provides insight into their operational duration. (Image source: Eaton)

Figure 5: A cross plot of energy density vs. power density of battery and supercapacitor devices provides insight into their operational duration. (Image source: Eaton)

The graph plots energy density vs power density. The ratio of those parameters yields time, which is also plotted on the graph. Devices with high energy density but low power density are in the upper left corner. These include fuel cells and batteries. Devices with high power density but low energy density, such as traditional capacitors and supercapacitors, occupy the lower right corner. Hybrid supercapacitors fit between those two groups. Note the time scale of each; supercapacitors work over periods of seconds, hybrids for minutes, and batteries for hours or more.

Energy storage applications

Energy storage devices supply power when primary power is lost. A good example is supplying backup power for computer memory. Batteries have previously been used, but supercapacitors are now finding their way into this application because of their significantly higher charge/recharge cycle counts. Further, with supercapacitors, there is no need to replace batteries after a year of operation.

Supercapacitors are also used in IoT and IIoT designs that rely on energy harvesting. They find similar applications in vehicles where they store energy reclaimed from braking.

Supercapacitors provide high power output for short periods. They can be applied to provide ‘ride-through’ power in critical installations that need to bridge the ten or so seconds delay until an emergency generator can come online. The supercapacitor recharges in about the same period as the usage period and can be back online quickly after a power loss.

Conclusion

Supercapacitors provide complementary operation to batteries in most energy storage applications. Their higher, immediately available power levels and fast recharge times make them ideal for short-term power support. The high number of charge/recharge cycles they can have without degradation in performance reduces battery replacement maintenance and inventory costs.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.