The Designer's Guide to Selecting a kHz Crystal

Contributed By DigiKey's North American Editors

2025-04-24

Products that keep time are practically ubiquitous and a facet of modern society. Telling time accurately needs a device like a quartz crystal that oscillates at a precise frequency and an integrated circuit (IC) to control it. A packaged clock module typically includes both the crystal and the controlling IC. Electronic oscillator circuits can be manufactured for frequencies from kilohertz (kHz) to megahertz (MHz).

kHz crystals can be sold as standalones or integrated into other products such as crystal oscillators (CXOs), digital temperature-compensated crystal oscillators (DTCXOs), and real-time clocks (RTCs).

Factors dictating the choice of a kHz crystal

While size and required frequency are the most important factors to consider when picking a kHz crystal for an application, a few other parameters are also essential for designing the right circuit.

They include:

- Frequency tolerance, stability, and aging

- Load capacitance (CL)

- Equivalent series resistance (ESR)

- Drive level (DL)

- Operating temperature

kHz crystals typically come with application-specific integrated circuit (ASIC) requirements that list the values of required parameters. ASIC information can provide a robust starting point for circuit design. The trend toward miniaturization of electronic circuits means designers need to pay extra attention to the factors listed above because the size and dense packing of components can affect a crystals properties and performance. Photolithographic manufacturing processes, however, ensure that the miniaturization of crystal oscillator circuits does not compromise the parameters needed for efficient operation.

Frequency tolerance, stability, and aging

While a crystal specifies a certain frequency, deviations can occur due to strains encountered during the manufacturing process or on surfaces during routine operation. Changes from specified frequency values can be summed up by evaluating three parameters: frequency tolerance, frequency stability, and aging.

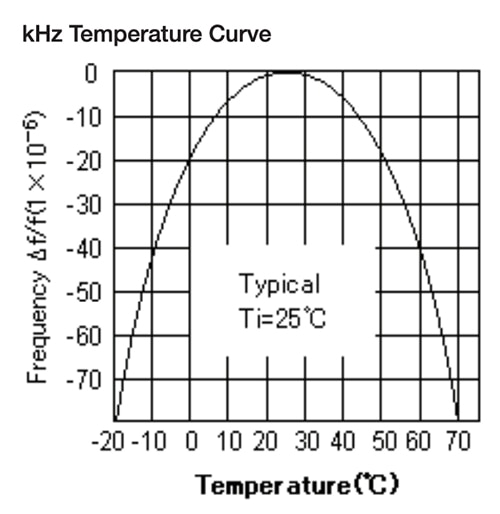

Frequency tolerance is defined as the difference between the actual frequency of a crystal from its nominal frequency at +25°C. Frequency stability is the maximum temperature-driven frequency shift that can occur across a set temperature range. To get more accuracy from a crystal, it is advisable to use a kHz XO, which takes frequency changes with temperature (Figure 1) into account and is calibrated accordingly. Finally, aging is the drift in frequency over time. Hermetic sealing reduces aging effects but may increase size.

Figure 1: Oscillator frequency changes with temperature and needs to be factored into the selection process, especially when the application is used in extreme environments. (Image source: Epson through IEEE)

Figure 1: Oscillator frequency changes with temperature and needs to be factored into the selection process, especially when the application is used in extreme environments. (Image source: Epson through IEEE)

Load capacitance (CL)

The capacitance between a crystal's two terminals is its load capacitance. Designers need to factor in external stray capacitance, which can cause frequency drift.

Attention to a mismatch between the CL and the circuit’s capacitance becomes especially important when using physically smaller crystals, which are more sensitive to capacitance changes. Low CL crystals are also especially frequency-sensitive. To design smaller circuits for tight spaces, design engineers usually choose crystals with a large CL.

Drive level (DL)

DL is the amount of current required to maintain a steady oscillation while keeping structural damage to a minimum. Selecting a crystal with a DL that meets or exceeds a given circuit’s drive level is recommended to avoid an unreliable frequency or premature failure.

Operating temperature

Temperature affects frequency beyond what might be specified in frequency stability numbers. While designers need to keep the overall circuit operating temperature in mind, they also need to factor in the crystal’s location in the circuit as some areas might be more prone to heat up than others. In addition, the smaller the circuit and the crystal, the more closely packed the components get and the more heat the entire system generates. In such cases, it’s best to use a crystal that’s better calibrated for a range of temperatures, like DTCXO or RTC products. DTCXO and RTC modules work well in compact designs, or in instances where high stability or low power is a priority.

kHz crystals and related modules

Epson manufactures a large number of kHz crystals as well as DTCXOs and RTC modules. A few of them are outlined below with their specifications.

The FC3215AN series are 32.768 kHz crystals with a low ESR of 35 kΩ in a compact package, which is well-suited for portable electronics and space-constrained applications. The FC3215AN series is ideal for a variety of applications, such as wireless modules, IoT, medical, industrial, security surveillance equipment, smart meters, consumer electronics, and low-power MCU applications. They support an extended operating temperature range from -40°C to +105°C and are available in a 3.2 mm x 1.5 mm x 0.9 mm package with standard pinouts.

The FC2012AN series 32.768 kHz crystals share similar specifications as the FC3215AN series and are available in a smaller 2.05 mm x 1.2 mm x 0.6 mm package with standard pinouts. Similarly, the FC2012SN series crystals (Figure 2) are ideal for a variety of applications, such as wearables, MCU, and wireless modules for IoT, medical, industrial, security, smart meters, and more.

Figure 2: Epson FC2012SN series feature a temperature range of -40°C to +105°C in a compact 2.05 mm x 1.2 mm package. (Image source: Epson)

Figure 2: Epson FC2012SN series feature a temperature range of -40°C to +105°C in a compact 2.05 mm x 1.2 mm package. (Image source: Epson)

The RX8901CE and RX4901CE real-time clocks from Epson are versatile and high-precision modules with low power consumption that are ideal for smart meters, security equipment, and smart lighting applications. The integrated system with up to three event inputs can be used to detect events and record their timestamp while the MCU remains in sleep mode, reducing system power consumption for longer battery life. The modules can record timestamps for 32 events in either FIFO or direct mode. They consume just 240 nA from a 3 V supply and feature a built-in power supply switching circuit that eliminates the need for external diodes and their losses. The modules offer time resolution down to 1/1024th of a second and are stable across their entire operating temperature range of -40°C to +105°C. The RX8901CE has an I²C interface, while the RX4901CE is available with a 3- or 4-wire SPI.

The RX8804 series RTCs (Figure 3) use DTCXO technology to achieve ±3.4 ppm or ±8 ppm accuracy over a range of -40°C to +85°C or -40°C to +105°C, respectively.

Figure 3: Epson RX8804 series low-power RTCs feature high accuracy over a wide temperature range. (Image source: Epson)

Figure 3: Epson RX8804 series low-power RTCs feature high accuracy over a wide temperature range. (Image source: Epson)

The RX8804 series has very low power at 0.35 µA typical, is available in a 3.2 mm x 2.5 mm x 1.0 mm surface-mount ceramic package, and includes a built-in crystal.

Finally, Epson’s TG-3541CE 32.768 kHz DTCXO is a precision frequency reference suitable for consumer and industrial applications, including IoT, wearables, mobile, sensors, GPS/GNSS, utility meters, and digital health and wellness. Specifically for IoT applications, the TG-3541CE’s precision time accuracy enables devices to sleep much longer and wake up less often to extend battery life. In addition, the standalone DTCXO can significantly improve MCU or RTC timing without any software changes, saving designers time and resources. The TG-3541CE is low-power, consuming only 1.0 µA, and available in a 3.2 mm x 2.5 mm x 1.0 mm surface-mount ceramic package.

Conclusion

Crystals, oscillators, RTCs, and DTCXOs are vital components in frequency control applications. Whether for wireless modules, IoT products, personal medical devices, or industrial equipment, Epson’s product offering can provide a solution to meet application-specific requirements.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.