Solving Leading Edge Detection Challenges in Material Handling with Wide-Beam Sensing

Contributed By DigiKey's North American Editors

2025-09-11

Material handling facilities today deal with the tough challenge of processing a wide range of packages at faster speeds while keeping detection accuracy high. E-commerce operations handle everything from thin mailers to bulky irregular boxes, and this package variety creates real detection headaches. Traditional narrow beam sensors cannot keep up with this diversity reliably. When detection systems fail to detect packages or set off false alarms, it results in missed shipments, routing errors, and a decrease in throughput.

This article breaks down why narrow beam detection struggles in material handling applications, explains how wide-beam retroreflective technology solves these problems, and walks through practical steps for implementing Banner Engineering's B25 wide-beam retroreflective sensor in automated sorting environments.

Package detection challenges in material handling

Retroreflective sensors operate by sending a light beam from the sensor to a reflector, which bounces the light directly back to the sensor's receiver. When an object passes between the sensor and reflector, it blocks the returned light, triggering a detection signal. This technology works reliably in many industrial applications because it requires only one mounting location for the sensor, with the reflector positioned opposite on the conveyor frame.

The challenge comes with beam width. Traditional narrow-beam retroreflective sensors create a focused detection point, typically just a few millimeters wide. While this precision works well for consistent packages, it creates problems in material handling where facilities process everything from thin mailers to bulky irregular boxes, often with varying positioning and conditions.

Several detection problems emerge with narrow beams. Uncentered packages may only partially interrupt the beam, leading to weak or inconsistent signals. Items with holes, tears, or open flaps can allow the beam to pass through unobstructed, even when a package is clearly present. Small objects like envelopes or flat mailers can slip past the narrow detection zone entirely, especially when traveling along the belt edge.

Conveyor belts themselves contribute to detection problems. Belt seams, surface variations, and normal belt flutter can trigger false positive signals, making it difficult to distinguish between actual packages and belt irregularities. Environmental factors like dust accumulation on sensors and reflectors gradually degrade performance, while temperature fluctuations affect sensor sensitivity.

These limitations show up as missed detections, false triggers, and reduced system throughput. In automated sortation systems, even small detection inconsistencies compound into significant operational disruptions. False triggers lead to unnecessary system stops, while missed detections send packages to incorrect destinations, leading to additional handling costs and customer service problems.

The fundamental limitation is that narrow beam sensors create a single detection point in applications that benefit from area coverage. Real-world material handling operations require more robust detection capabilities that can handle diverse package types and positioning conditions reliably.

Wide-beam retroreflective technology: a better approach

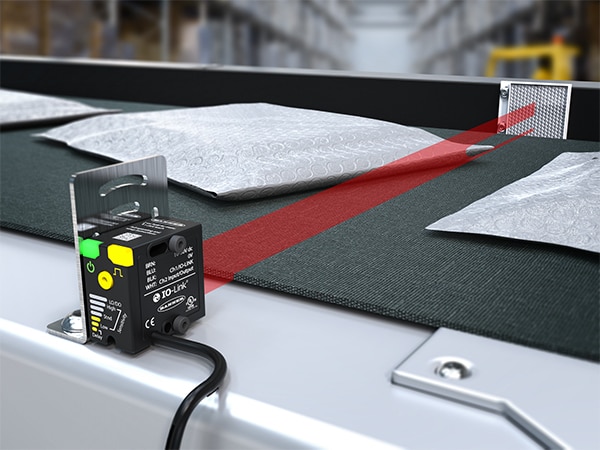

Wide-beam retroreflective sensing addresses the fundamental limitations of narrow beam detection by expanding the sensing area while maintaining the reliability and simplicity of retroreflective technology. An example is Banner Engineering’s B25 wide-beam retroreflective sensor as shown in Figure 1.

Figure 1: Banner Engineering's B25 wide-beam retroreflective sensor with LED indicators and TEACH button (round yellow). (Image source: Banner Engineering)

Figure 1: Banner Engineering's B25 wide-beam retroreflective sensor with LED indicators and TEACH button (round yellow). (Image source: Banner Engineering)

The B25 wide-beam retroreflective sensor creates a 25 mm wide detection zone instead of the narrow point detection of traditional sensors. This expanded coverage area means packages don't need to be precisely positioned to trigger reliable detection. Whether a package is centered on the conveyor or positioned toward one edge, the wide-beam provides consistent detection coverage, as demonstrated in Figure 2 with challenging thin mailers and polybags.

Figure 2: B25 wide-beam sensor detecting thin mailers with 25 mm beam coverage. (Image source: Banner Engineering)

Figure 2: B25 wide-beam sensor detecting thin mailers with 25 mm beam coverage. (Image source: Banner Engineering)

This approach particularly helps with packages that have holes, tears, or irregular edges. While a narrow beam might pass through a gap in a damaged package, the wide-beam coverage makes it much more likely that some portion of the package will block enough light to trigger detection. The sensor can reliably detect objects as small as 3 mm anywhere within the 25 mm sensing area, making it effective for both small envelopes and larger packages. Figure 3 illustrates this capability with a tote that has openings that would allow a narrow beam to pass through undetected.

Figure 3: Wide-beam detection of objects with holes and irregular shapes using the B25 wide-beam sensor. (Image source: Banner Engineering)

Figure 3: Wide-beam detection of objects with holes and irregular shapes using the B25 wide-beam sensor. (Image source: Banner Engineering)

Real-world performance advantages using smart learning capabilities

The B25 includes adaptive learning features that automatically adjust to conveyor conditions. The sensor can learn to distinguish between normal belt characteristics and actual packages. This helps filter out false triggers from belt seams, surface variations, and normal belt movement. The system automatically optimizes detection thresholds based on the operating environment.

In conveyor applications, the B25's wide-beam detection provides more reliable leading edge detection regardless of package shape or position. This translates to better timing control for divert operations and more accurate package routing in sortation systems.

The learning capabilities help maintain performance over time by adapting to environmental changes like dust accumulation or temperature variations. This reduces the need for frequent recalibration and helps maintain consistent detection reliability in demanding industrial environments.

With response times under 0.5 ms and industrial-grade construction (IP67 rating, operating range from -30°C to +60°C), the B25 handles high-speed operations while withstanding harsh material handling environments.

Implementing B25 sensors in material handling systems

Getting B25 sensors up and running in material handling systems involves straightforward installation and configuration steps that build on standard industrial practices.

Start with proper sensor positioning. Mount the B25 so it faces perpendicular to the reflector, accounting for conveyor width and the range of package heights that need detection. The sensor works effectively up to 2 m from the reflector, giving flexibility in positioning for different conveyor configurations.

The appropriate reflector for most applications is the BRT-51X51BM square reflector, which works well for most material handling setups. Make sure both the sensor and reflector are securely mounted to prevent vibration-induced alignment issues.

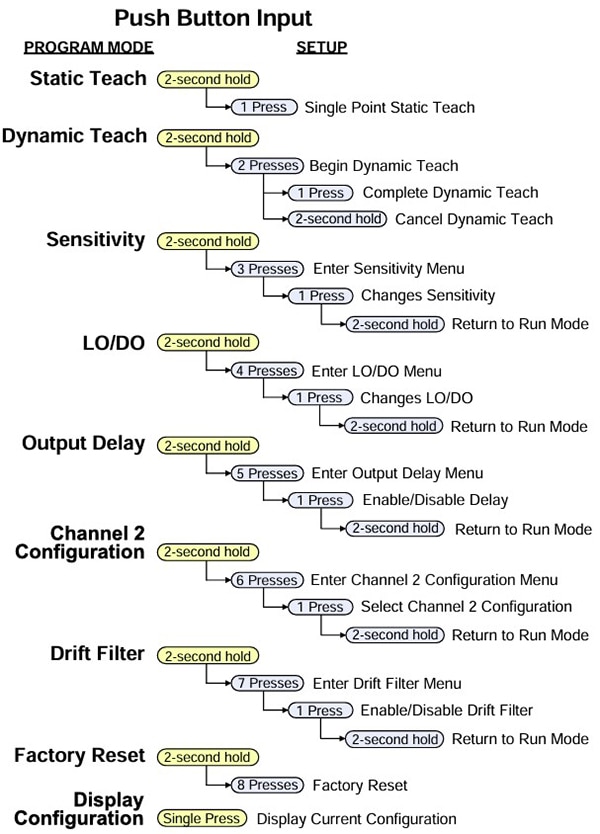

The configuration process is designed to be straightforward. For basic applications, the built-in TEACH button with LED bar graph provides clear feedback on current settings. Static TEACH works well when package types and conveyor conditions are consistent, while Dynamic TEACH adapts better to mixed applications with varying packages and belt characteristics. The configuration chart in Figure 4 shows the complete range of setup options available through the TEACH button interface.

Figure 4: B25 wide-beam sensor configuration options using the TEACH button and LED indicators. (Image source: Banner Engineering)

Figure 4: B25 wide-beam sensor configuration options using the TEACH button and LED indicators. (Image source: Banner Engineering)

For sensors mounted in hard-to-reach locations, the remote input programming option allows configuration through the wiring connections using simple pulse sequences.

The B25 sensor integrates easily with existing control systems through standard discrete outputs. The 4-pin M12 connector provides power, discrete outputs, and IO-Link communication in a single connection. For facilities already using IO-Link infrastructure, the B25 sensor can provide enhanced diagnostics and real-time monitoring data.

Banner provides add-on instruction (AOI) files for Rockwell Allen-Bradley PLCs, which can simplify integration and provide access to advanced sensor features through existing programming environments.

Most installations can be completed using standard industrial mounting hardware and electrical connections, making the B25 wide-beam sensor a practical upgrade path for existing narrow beam sensor applications.

Conclusion

Wide-beam retroreflective sensing technology addresses the detection challenges that narrow beam sensors face in diverse package environments. The B25 wide-beam sensor’s 25 mm coverage area reliably detects objects as small as 3 mm regardless of positioning, handles packages with holes and irregular edges, and automatically adapts to belt characteristics. For material handling operations struggling with missed detections and false triggers, the B25 sensor provides improved reliability while maintaining the simplicity of traditional retroreflective technology.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.