Selecting and Applying a Linear Position Sensor for Rugged Vehicle Controls

Contributed By DigiKey's North American Editors

2024-02-21

With the Internet of Things (IoT) for factory automation and the increasing use of electronics in vehicles, designers must carefully consider their sensor options. Vehicles such as tractors and forklifts present unique design challenges regarding linear sensors for controls. These controls must be precise, responsive, reliable, and durable, coping with temperature extremes, shock, vibration, dust, and moisture for many years with minimal maintenance.

One option that meets the requirements for these applications is the linear Hall effect sensor. As a non-contact option, these sensors can be ruggedized to withstand harsh working conditions.

This article discusses the sensing requirements of vehicles and what makes linear Hall effect sensors a good option. It then presents linear Hall effect sensors from Vishay to illustrate their characteristics and how to select and apply them successfully.

Why rugged vehicles need specialized, high-precision controls

Rugged vehicles often operate in hazardous environments where precise operation is a requisite. Thus, the controls for these vehicles must be highly accurate and responsive. Moreover, these operator controls often need to interface with several on-board IoT sensors and automated control systems. Example applications include:

- Forklift tillers: Accurately detecting the tiller angle (i.e., the main control handle) enables safe and efficient maneuvering, which is especially important in tight spaces.

- Tractor gear shifts: Smooth gear changes minimize wear and tear on the transmission and improve fuel efficiency.

- Pedal displacement systems: Precise measurements allow optimal vehicle control and enhance safety features such as automatic speed reduction and emergency stop.

Reliability is another design requirement. In environments such as warehouses and manufacturing facilities, the controls may be exposed to contaminants, temperature extremes, and physical abuse.

Finally, rugged vehicles are often space-constrained by design. For example, forklifts are highly compact to optimize maneuverability in warehouse aisles. Thus, the sensors for rugged vehicle controls typically need to be as small as possible.

Why linear Hall effect sensors are uniquely suited to rugged vehicle controls

Choosing a suitable sensor for rugged vehicle controls can be difficult due to the need for durability, long stroke distances, and small size. Linear Hall effect sensors are a good option because they are a non-contact technology that can serve millions of cycles without adjustments. In addition, they are available in compact, easy-to-mount packages and offer excellent precision for short-range position detection.

It is helpful to first examine the Hall effect to understand these benefits. A Hall effect sensor applies a fixed DC bias current along one axis and across a thin strip of metal or semiconductor called the Hall element. When a magnetic field is applied perpendicular to the current flow, the charge carriers are deflected by the Lorentz force and accumulate on opposite sides of the Hall element, creating a transverse electric field called the Hall field and a potential across the element called the Hall voltage. The Hall voltage is proportional to the product of the current, the magnetic field, and a material-dependent constant known as the Hall coefficient.

In a linear sensor, the Hall effect can create an output voltage proportional to the distance between the Hall element and a magnet. This results in highly accurate position sensing over short distances with fast response times.

A linear Hall effect sensor designed for rugged vehicle controls

The 20LHE series position sensors from Vishay (Figure 1) exemplify the benefits of linear Hall effect sensors. They have a short stroke of 10 millimeters (mm) and a tracking speed of 60 mm per second (mm/s). They are well-suited for high-precision vehicle controls due to their linearity, which can be specified as low as ±1%.

Figure 1: The 20LHE series linear Hall effect position sensors feature a linearity of ±1%. (Image source: Vishay)

Figure 1: The 20LHE series linear Hall effect position sensors feature a linearity of ±1%. (Image source: Vishay)

The 20LHE series sensors are designed to operate in harsh environments and have a maintenance-free lifespan of over 10 million cycles. The sensors provide accurate measurements when power is applied without calibration or initialization. Additionally, these sensors provide excellent stability with no drift of linearity. Static hysteresis is limited to 0.1% of the supply voltage, while dynamic hysteresis is only 0.25%.

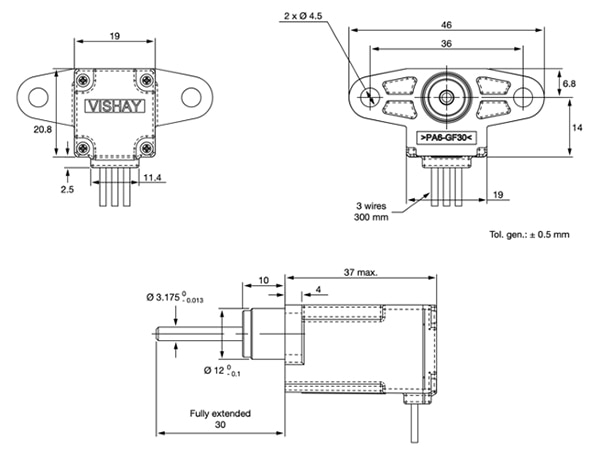

The sensors are flange mounted for easy installation, as shown in Figure 2, and the shaft can extend 30 mm from the mounting face to facilitate the connection with the control mechanism. At the same time, the overall dimensions of a 20LHE series sensor are just 46 x 20.8 x 37 mm, allowing the device to fit into cramped vehicle cabins.

Figure 2: The 20LHE series sensors are compact and use a flange-mounted design for easy mounting. (Image source: Vishay)

Figure 2: The 20LHE series sensors are compact and use a flange-mounted design for easy mounting. (Image source: Vishay)

Mechanical design considerations for linear Hall effect sensors

Rugged vehicle controls must offer high reliability in uncontrolled settings. Thus, it is crucial to consider the ability of a vehicle control sensor to withstand rough treatment. Physical impact is likely in harsh conditions, as is vibration from sources such as the vehicle engine and suspension. The 20LHE series sensors offer a rugged physical design that can withstand vibration up to 20 g and shock up to 50 g.

The 20LHE series sensors are housed in a durable thermoplastic enclosure to handle dust, liquids, and extreme temperatures of -40°C to +85°C. Models with a spring return have an environmental ingress protection (IP) rating of IP51; higher IP ratings are also available.

An IP rating indicates the level of protection an enclosure provides against the intrusion of solid objects (first digit) and liquids (second digit). In the case of IP51, 5 indicates that the enclosure is protected against the ingress of dust in an amount sufficient to affect the normal operation of the device, while 1 indicates that the enclosure is protected against vertically falling drops of water.

Electrical design considerations for using linear Hall effect sensors

Rugged environments also present electromagnetic hazards, including electrostatic discharges and inadvertent interactions between various electrical and electronic systems. The 20LHE series can withstand a wide range of such hazards. Most notably, they can resist an overvoltage of +20 volts and a reverse voltage of -10 volts. Other environmental specifications are listed in Table 1.

|

Table 1: The 20LHE series is designed to withstand physical and electromagnetic hazards. (Image source: Vishay)

A linear Hall effect sensor must be paired with a load resistance to operate correctly. For the 20LHE series, Vishay recommends a minimum load of 1 kilohm (kΩ).

Selecting a linear Hall effect sensor

Accuracy is the first parameter to consider, as the sensor must support the required control precision. In the case of the 20LHE series, Vishay offers a choice of either ±2% linearity with the 20LHE1XWA1P30 or ±1% linearity with the 20LHE1AWA1P30.

The output should also match the needs of the rest of the control system. Typical options include analog ratiometric or pulse width modulation (PWM). The 20LHE series is available in both configurations, with the output increasing or decreasing relative to the sensor position. For example, the 20LHE1AWB1P30 has an analog decreasing output, meaning the output is at its lowest when the sensor shaft is fully compressed (Figure 3).

Figure 3: The 20LHE1AWB1P30 is available with an analog decreasing output, which reaches its minimum when the sensor shaft is fully compressed. (Image source: Vishay)

Figure 3: The 20LHE1AWB1P30 is available with an analog decreasing output, which reaches its minimum when the sensor shaft is fully compressed. (Image source: Vishay)

The shaft itself bears consideration. For example, the 20LHE series has a 3.175 mm shaft that can be optionally threaded with an M3 x 6 mm thread. Such a configuration can simplify installation and provide a more secure connection to the control mechanism.

Most 20LHE series models come equipped with a spring return. This spring provides a self-centering mechanism, ensuring that the sensor returns to its original position when the force that displaced it is removed. This feature can benefit vehicle control applications such as throttle position sensors, where operators frequently apply and release input forces. Models without a spring, such as the 20LHE2AWA1P30, are also available.

Conclusion

As a non-contact option, linear Hall effect sensors are an excellent fit for rugged vehicle controls. The 20LHE series comes in a compact form factor and is flange-mounted for easy installation. They are also durable enough to withstand harsh working conditions and deliver stable, maintenance-free precision in the face of physical and electromagnetic hazards.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.