RGB LED Indicators for Embedded Systems and Displays

Contributed By DigiKey's North American Editors

2025-05-30

An electronic circuit often needs to relay the status of its operations, and a light-based indicator is an easy way to do so. Among lighting solutions, LEDs consume less energy than traditional sources. They can operate on low power, which is an advantage in embedded systems instrumentation where battery energy might be at a premium.

If operations call for a basic signaling system with only red, yellow, and green colors, a simple RYG indicator could work. In such cases, red would indicate danger or stop, while a green light would indicate that all systems are functioning as they should. RYG systems offer a traditional solution used in basic dashboards and industrial signaling towers.

Red, green, and blue (RGB) LED indicators perform visual display functions by illuminating in different colors depending on the status they want to convey. RGB LED indicators offer a rich palette of colors and more visually nuanced information. A range of temperatures in a gradient bar, for example, will need varying shades of colors to signify intensity.

Further, an RGB LED indicator can perform the function of two or three different indicators by being modulated to display a desired color, resulting in a smaller space requirement.

RGB LED indicators are used in a variety of applications, including display screens in rugged machinery, smart home equipment, and embedded systems in industrial applications. For example, the Q10/14/16/19/22 Series RGBs (Figure 1) from APEM offer practically infinite color options with 100,000 hours of lifetime operation. RGB LEDs are usually the components of choice for modern-day instrumentation because they are capable of more colors while also consuming less energy.

Figure 1: APEM's Q10/14/16/19/22 Series RGB LED indicators are controlled by pulse width modulation (PWM) to produce a multicolored appearance. (Image source: DigiKey).

Figure 1: APEM's Q10/14/16/19/22 Series RGB LED indicators are controlled by pulse width modulation (PWM) to produce a multicolored appearance. (Image source: DigiKey).

How RGB LEDs work

A driver controls the color display by controlling the current sent to the LEDs. It uses 8 bits to represent the amount of color desired in each channel (R, G, or B). For example, the 8-bit representation 00000000 in the red channel means there should be no red in the final composition. Because each 8-bit representation can be a combination of 0s and 1s, each color module can have 28 or 256 different values, from zero to 255.

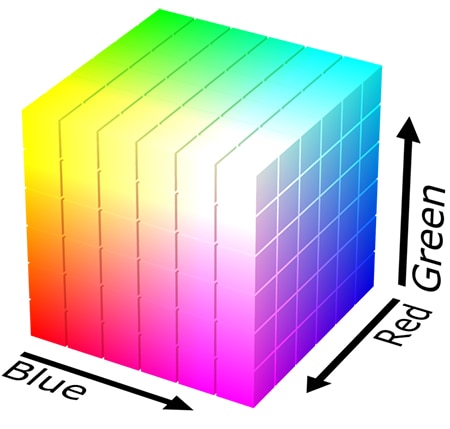

Each of those 256 values represents a very slight variation in the intensity of the red, green, and blue colors. By tuning each of these 256 values in the red, green, and blue elements in different combinations, circuit designers can get millions of hues, specifically 256 x 256 x 256, or 16.7 million colors (Figure 2).

Figure 2: The RGB color model mapped to a cube. The horizontal x-axis represents red values increasing to the left, the y-axis represents blue values increasing to the lower right, and the vertical z-axis represents green values increasing toward the top. The origin, black, is the vertex hidden from view. (Image source: SharkD, CC BY-SA 4.0; Wikimedia Commons)

Figure 2: The RGB color model mapped to a cube. The horizontal x-axis represents red values increasing to the left, the y-axis represents blue values increasing to the lower right, and the vertical z-axis represents green values increasing toward the top. The origin, black, is the vertex hidden from view. (Image source: SharkD, CC BY-SA 4.0; Wikimedia Commons)

The RGB values for the color fuchsia, for example, would have the following settings for the three components: R: 255, G: 0, B: 255. Meanwhile, the RGB values for chartreuse would be: R: 223, G: 255, B: 0.

To get the RGB LED indicator to display a specific color, the intensity of the red, green, and blue components have to be fine-tuned by manipulating the power delivered to each color module. There are two ways of dynamically dimming an LED: constant current reduction (CCR) and pulse width modulation (PWM).

The CCR method reduces the amount of current sent to the LED, which causes the light output to change. This method is simple and has some advantages. The PWM method, on the other hand, keeps the amount of current constant, but instead of continuously sending current to the LED, it is sent in rapid pulses, turning the LED on and off many times a second. The resulting light intensity of the LED is proportional to the fraction of the time that the current is on, called the “duty cycle.”

PWM is an especially useful technique in controlling RGB LED indicators because it enables granular control over the final color output. Additionally, PWM lends itself easily to digital control using microcontrollers, which toggle outputs between high and low states.

Aesthetics for RGB LED indicators

If indicators are to be used in the displays and control panels of electrical instruments and human-machine interfaces (HMIs), they need to integrate more fully with the devices. Traditional two-pin LEDs typically require a solid base to hold them in place, and the indicators often protrude through holes in the panel. Protruding LED indicators might not align with the aesthetics of the unit that designers have in mind. In addition, protrusions run the risk of being easily damaged.

On the other hand, panel mount indicators fasten to the panel, making design and installation much easier. In such cases, bezels serve as the mounting mechanism, and they are aesthetically pleasing. The bezel option offers a polished look instead of having the LED protrude from the panel and be susceptible to damage.

Even within bezel options, RGB LED indicators can have a flush bezel mount or a prominent one. The flush bezel lies flat against the panel, offering a sleek and modern look. The prominent or raised bezel, on the other hand, has an LED cap that protrudes slightly above the surface. Such slight protrusions are especially useful if the display needs to be viewed from various angles. The raised bezel mount is easier to identify in sunny outdoor environments or industrial settings with harsh lighting. The choice of bezel ultimately depends on the final application. Harsh lighting environments require indicators that are more easily visible, making the raised version a better option. If aesthetics is the sole concern for design engineers, the flush mount is a better option.

In addition to bezels, the mechanics of the installation of panel mount indicators require circuit designers to determine panel cutouts that accommodate them. Cutouts can be snap-fit for faster installation, but snap-fits will need more precise cuts. Nuts can also be used to thread the indicators into the panel for more security, especially in environments prone to high vibration. Sizes of the panel cutouts can vary. APEM’s Q series RGB LED indicators are available in 10, 14, 16, 19, and 22 mm cutouts, and feature both flush and prominent bezels.

Selecting the right RGB LED indicator

Given the various options, here are some of the criteria used to match the right LED indicator to a given application:

- Common anode or cathode: In the common anode, the three red, green, and blue components share a positive (anode) connection, while they share a negative connection in the common cathode connection. Different electronic components are required for the LED driver to utilize common anode versus common cathode packages.

- Through-hole or surface mount: The type of installation of the RGB LED indicator

- The size of the indicator and the panel cutout: (if using panel surface mount options)

- The brightness of the LED indicator and its viewing angle

- Voltage and current ratings: These need to match expected ranges in the circuit to ensure reliable performance

- Control methods for the LED indicators: These can vary from using separate PWM channels through a microcontroller, or driver integrated circuits, which provide even more granular tuning options.

- Environmental considerations: Vibration, shock, dust, and extreme heat or cold—will dictate the kind of LED required for specific applications.

The Q series of RGB LED indicators

The Q series from APEM offers combined illumination with intense RGB light output and brighter illumination as opposed to the RYG option. Recessed options are available to fit panel aesthetics. The Q series has an epoxy resin sealing option to prevent water ingress, which is necessary in outdoor applications or indoor settings with high humidity.

In addition, the Q series offers standard, hyper-bright, and super-bright options. While the standard is suitable for any indoor application, the hyper-bright choice is made for outdoor applications where viewing angles are important. The super-bright option is also a daylight visible LED but has a much narrower viewing angle, which is well-suited for long distances.

Conclusion

RGB LED indicators are a good fit for modern electronics as they deliver visual signals while expending minimal energy. In addition, the indicators in the APEM_Q10/14/16/19/22 series are feature-rich and offer customers a wide variety of options to suit almost any application requiring panel indication.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.