Mounting Speakers: Important Tips and Considerations

2025-04-30

How a speaker is integrated within an electronic system plays a critical role in determining acoustic performance, often outweighing the intrinsic quality of the speaker itself. A high-specification speaker can underperform if improperly implemented, while a lower-end unit may deliver satisfactory or even superior results when optimally coupled to its acoustic and mechanical environment. Key variables such as usable SPL (sound pressure level), enclosure resonance, and vibration isolation are pivotal factors in system design. Proper speaker mounting, though frequently overlooked, is an essential aspect of electroacoustic engineering.

Prior to speaker selection, it is essential to conduct a thorough analysis of the operating environment and use-case requirements. For instance, will the system operate in a high-noise industrial zone where intelligibility and output power are paramount? Or is it intended for low-noise settings where accurate audio reproduction is key? Considerations such as system portability, end-user orientation relative to the device, and enclosure constraints must be evaluated early in the design phase. These inputs directly influence the required frequency response, SPL targets, power budget, and allowable trade-offs in terms of weight and material selection. This article will dive further into common speaker mounting styles, enclosure design considerations, and more to help aid engineers in the speaker selection and design process.

Additionally, for a deeper technical breakdown of speaker characteristics, such as cone composition, magnet structures, and performance metrics, refer to Same Sky’s detailed post: The Complete Guide to Speaker Selection.

Speaker termination and mounting types

Speakers are available with a variety of termination types, including pre-attached wire leads, solder pads, spring contacts, surface-mount terminals, and through-hole pins. Irrespective of the electrical termination method, the mechanical integration of the speaker typically involves securing the outer frame directly to the system enclosure. This is commonly accomplished via mounting holes for screw fasteners or adhesive bonding. In either approach, achieving an airtight mechanical seal between the speaker frame and the enclosure is critical to maintain acoustic integrity and prevent undesirable air leakage, which can degrade low-frequency performance.

For speakers supplied with wire leads, the leads are routed and terminated according to the system’s wiring architecture. Devices with solder pads require manual wire soldering; these conductors are then routed similarly to factory-wired units. It is important to clarify a common misinterpretation: speakers with solder pads are not designed for direct PCB attachment via SMT processes. These units are not surface-mount components and should not be reflow-soldered onto a PCB—they are intended for point-to-point wiring.

Spring-contact models rely on mechanical pressure from the final device assembly to maintain electrical contact, eliminating the need for soldering and enabling straightforward field replacement. This approach is particularly useful in modular or serviceable designs.

Speakers with surface-mount terminals, designed specifically for reflow soldering, can be directly mounted onto a PCB using standard SMT processes. These typically come housed in a compact, fully enclosed package that does not require direct coupling to the device's outer housing. Similarly, speakers with through-hole pins can be soldered directly to a PCB using wave or hand soldering techniques.

Ultimately, the optimal combination of mounting and termination style (Figure 1) will be dictated by the mechanical constraints, assembly methods, servicing requirements, and overall electrical architecture of the end product.

Figure 1: Common mounting and termination types for speakers. (Image source: Same Sky)

Figure 1: Common mounting and termination types for speakers. (Image source: Same Sky)

Enclosure design and materials

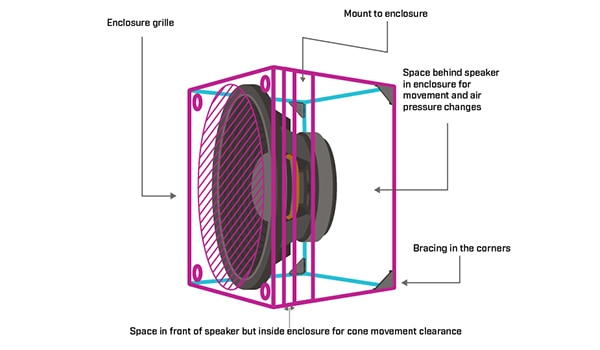

Cavity volume, both in front of the speaker and behind the speaker, plays a significant role in defining overall acoustic performance, particularly in terms of the resonance and drive of a speaker. The front cavity acts not only as the path for sound, but also as a protective interface against the environment. To safeguard the diaphragm while preserving acoustic transparency, designers often employ a thin acoustic mesh or grille. In harsher environments where mechanical protection is needed, a rigid baffle with precision-drilled holes or slots is typically used. Even with up to 80% coverage of the speaker, this configuration allows sufficient sound transmission while shielding the transducer from physical intrusion or debris. When integrating a protective front element, it is also essential to maintain adequate clearance for diaphragm movement. In micro speaker designs, a conservative rule of thumb is to allocate at least 1–2 mm of clearance to prevent mechanical interference.

Smaller form factor speakers further require a delicate balance between spatial efficiency and acoustic fidelity. As a baseline, rear cavity depth roughly equal to the speaker’s diameter often yields a good compromise between enclosure size and sound quality. For larger speakers, however, rear volume becomes a dominant factor. Diaphragm motion induces pressure changes in the back cavity; if this space is undersized, it introduces back pressure that directly opposes cone movement, resulting in distortion and reduced efficiency.

To mitigate these issues, the front and rear acoustic chambers must be isolated using an airtight mechanical barrier (Figure 2). This junction not only seals the front and back cavities but also serves as the mechanical mounting interface for the speaker. Again, ensuring adequate rear cavity space will also limit the amount of air trying to escape through this junction. Given the high dynamic motion of loudspeakers, a common and effective approach is to implement a compression seal using high-density foam, which ensures a tight fit while limiting any mechanical buzz, rattle, or unwanted vibration during operation.

Figure 2: Basic speaker mounting considerations (Image source: Same Sky)

Figure 2: Basic speaker mounting considerations (Image source: Same Sky)

A properly mounted speaker should exhibit no unintended vibration or buzzing. However, enclosure performance is also influenced by the mounting material. Thin plastics—commonly used in modern compact devices—may flex or resonate, introducing acoustic artifacts. To avoid this, select materials with sufficient stiffness and damping characteristics. If high output levels are expected or if the enclosure lacks structural rigidity, internal bracing (as shown in Figure 2) may be required.

Final testing and design

While aesthetics may be secondary for many engineers, visual design and user interaction should not be overlooked. Speaker placement, mounting methods, and protective elements must consider both function and form. A well-performing speaker that lacks visual appeal can impact product marketability. Collaborating with an industrial designer or integrating aesthetic considerations early ensures the final product is both acoustically optimized and visually compelling.

After design and planning, early-stage prototyping is critical. Build and test a functional prototype to validate acoustic performance. Conduct listening evaluations and quantitative tests using tools such as calibrated microphones and frequency analyzers to assess frequency response, resonance, and distortion. Be prepared to revise mounting, enclosure design, or speaker placement based on test results. In some cases, performance can be improved without major redesigns, such as adding internal damping materials to reduce unwanted enclosure resonance.

Conclusion

Overall, speaker performance is heavily influenced by how it is mounted within a device or enclosure. By clearly defining application requirements, applying sound integration practices, and validating performance through testing, the selected speaker can meet its design targets and deliver optimal results. For audio solutions, Same Sky offers a broad range of miniature and standard speakers, along with audio design services to ensure sound performance goals are achieved.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.