Matching Temperature Sensor Factors to Application Needs

Contributed By DigiKey's North American Editors

2025-03-28

Choosing the optimal temperature sensor for an application can be challenging, given the variety of sensor technologies available and the diverse industry requirements. However, many applications require exact readings, so it is essential to examine the wide range of options that are available.

Selecting a temperature sensor involves balancing multiple factors to meet design requirements, such as accuracy, response time, communication protocol, environmental robustness, power usage, cost, and system integration. Sensors generally fall within four analog voltage output categories, and a fifth that utilizes a digital signal output:

- Thermocouples have a wide temperature range and durability, measuring from cryogenic temperatures to over +1,800°C. They are rugged and can withstand harsh environments and respond quickly to rapid temperature changes. But they’re less accurate and stable than other options and require signal conditioning. They are well-suited for heavy industry, such as steel and glass production, and in-home and commercial appliances with high heat.

- Resistance temperature detectors (RTDs) are highly accurate and stable. They're ideal for industrial automation and process control where precision is crucial. RTDs are commonly used in the food and pharmaceutical industries for tight temperature control in processes like brewing, sterilization, and frying. They provide accurate temperature measurements for HVAC systems, and in laboratory and medical equipment like incubators and analytical instruments. RTDs can be expensive compared to alternatives like thermocouples and are fragile due to their reliance on fine wire or thin film sensing elements. They are often used with a precision measurement circuit that adds to design complexity and cost.

- Thermistors are temperature-dependent resistors made from semiconductors that exhibit high sensitivity. Large resistance changes for small temperature shifts enable the detection of minute fluctuations and high resolution. Small, fast, and low-cost, thermistors are available in various sizes from tiny beads to larger probes. They excel in applications with limited temperature spans, typically between -50°C and 150°C. Thermistors are very versatile, finding use in medical devices and consumer electronics, where ambient or body temperature is relevant, as well as automotive applications, battery management systems, consumer appliances, and fire and smoke detection. However, their non-linear resistance curve requires conversion formulas or lookup tables to translate resistance to accurate temperature, and they may experience drift over time compared to RTDs.

- Diode-based temperature sensors provide fast response times and are smaller than the other three analog types. They can readily interface with a microcontroller, analog-to-digital converters (ADCs), and application-specific integrated circuits (ASICs). They are cost-effective with a limited temperature range of -55°C to +150°C, and are utilized in a wide range of applications spanning consumer electronics, industrial automation, data center storage systems, automotive, and many others. They exhibit lower accuracy than RTDs, are susceptible to system noise, and often require calibration to ensure consistent readings between different devices.

- Digital temperature sensors are integrated circuits (ICs) that measure temperature and provide a direct digital output, typically over communication protocols like SMBus, I²C, SPI, or 1-Wire. They don't require the external signal conditioning, amplification, and analog-to-digital conversion of the analog options.

Selection guidelines

Choosing the appropriate temperature sensor involves balancing accuracy, response time, durability, and cost. Industry-specific requirements can also guide the selection of a suitable component.

The operating environment of the application plays a crucial role. Harsh conditions necessitate robust sensors like thermocouples or coated RTDs, while thermistors or semiconductor sensors are more suitable for controlled environments. Cost and scalability are also factors to consider in mass production—thermistors are economical, but RTDs and high-end thermocouples offer long-term stability.

The designer's tolerance between accuracy versus practicality can also impact selection. RTDs provide high precision but are expensive, while thermocouples are more versatile but less accurate. Response time and placement also matter—small, low-mass sensors like thermocouples and thermistors respond quickly, but their placement can impact performance.

The cost of a sensor and its associated circuitry can heavily influence selection, especially in consumer products or high-volume manufacturing. There is a considerable cost range among sensor types. Analog sensors require signal conditioning, while digital sensors simplify integration. Reducing analog circuitry and calibration can minimize overall costs and justify the use of even a slightly more expensive digital sensor.

Digital options and characteristics

Digital sensors convert an analog signal internally and transmit data as a digital stream, often providing better noise immunity and enabling more complex data processing. Analog Devices, Inc. (ADI) offers a broad portfolio of analog and digital temperature sensors, and designers should carefully evaluate which best matches the needs of their application. Following is a brief recap of some digital sensors.

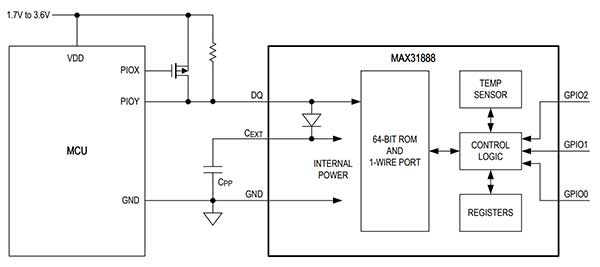

When exact temperature readings are necessary, accuracy is likely the top selection factor. ADI's MAX31888 digital sensor features ±0.25°C accuracy over a range of -20°C to +105°C, and communicates with a microcontroller over a 1-Wire bus to enable high-precision temperature monitoring circuits (Figure 1). Programmed into each MAX31888 is its own unique 64-bit registration number, which acts as the node address in a multi-drop 1-Wire network.

Figure 1: A typical application circuit using the MAX31888 temperature sensor. (Image source: Analog Devices, Inc.)

Figure 1: A typical application circuit using the MAX31888 temperature sensor. (Image source: Analog Devices, Inc.)

The MAX31888 utilizes just one data line for communication, from which it can directly draw parasitic power, allowing designers to do without an external supply. When using external power supplies, its voltage range is from 1.7 V to 3.6 V while consuming only 68 μA of current during measurement.

Power consumption and size may be the top concern when designing small, battery-operated devices. For applications such as wearables, ADI's MAX31875 devices, such as the MAX31875R0TZS+T (Figure 2), combine a very small package size of 0.84 mm x 0.84 mm x 0.35 mm and low supply current consumption with a temperature measurement accuracy of ±1°C.

Figure 2: Representation of the MAX31875R0TZS+T form factor. (Image source: Analog Devices, Inc.)

Figure 2: Representation of the MAX31875R0TZS+T form factor. (Image source: Analog Devices, Inc.)

The MAX31875 family uses an I2C/SMBus-compatible serial interface that uses standard write byte, read byte, send byte, and receive byte commands to read temperature data and configure sensor behavior in a typical circuit (Figure 3). It uses <10 μA average power supply current and can measure temperatures from -50°C to +150°C.

Figure 3: An application circuit using a MAX31875 digital temperature sensor. (Image source: Analog Devices, Inc.)

Figure 3: An application circuit using a MAX31875 digital temperature sensor. (Image source: Analog Devices, Inc.)

ADI also offers ICs designed to precisely measure the temperature of thermal diodes and convert it into a digital format, replacing conventional thermistors or thermocouples. These remote diode sensors measure the temperature of external PN junctions, like the thermal diodes built into CPUs, GPUs, FPGAs, and ASICs. The MAX6654MEE+T measures one thermal diode. Other options are available for 2, 3, 4, and 8-channel applications.

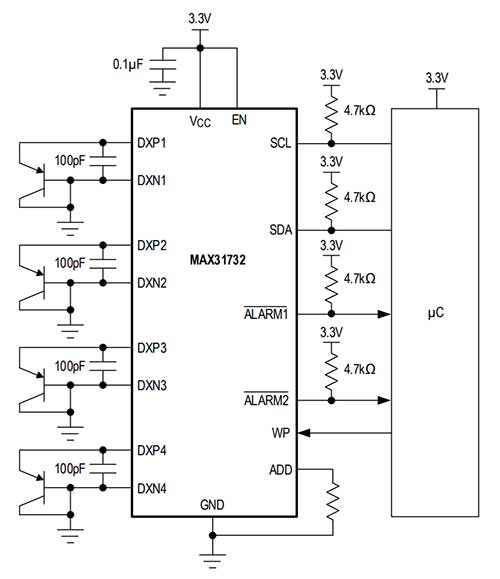

Remote diode sensors can be widely employed in electrically noisy environments with appropriate internal and external filtering. The MAX31732ATG+T is a 4-channel temperature sensor that monitors its own temperature along with the temperatures of up to four external diode-connected transistors (Figure 4).

Figure 4: ADI's MAX31732 can monitor up to four external diode-connected transistors as in this application circuit. (Image source: Analog Devices, Inc.)

Figure 4: ADI's MAX31732 can monitor up to four external diode-connected transistors as in this application circuit. (Image source: Analog Devices, Inc.)

The MAX31732 sensor can be programmed to set temperature thresholds without any special software or firmware. A 2-wire serial interface can be used to monitor temperatures and revise temperature thresholds.

Conclusion

Finding the optimal temperature sensor can ensure better performance, reliability, and cost-efficiency in an application. Selection can be impacted by a range of factors, including industry-specific requirements and standards, and cost-versus-performance trade-offs. ADI's digital temperature sensor portfolio offers solutions to meet the needs of a wide variety of applications.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.