Matching Industrial Power Connectors to Application Requirements

Contributed By DigiKey's North American Editors

2025-07-22

Powering industrial equipment, whether on the factory floor, at a construction site, or in a data center, requires cable connectors designed to meet the specific needs of each installation, ensuring safe, reliable, and long-lasting connections. Specific installations may require resistance to water or industrial chemicals, as well as protection against dust or ultraviolet light. Connectors must withstand the mechanical stress of repeated connection and disconnection cycles, where contacts may be exposed to contamination. At the same time, they must ensure the safety of users and equipment.

For designers, the primary challenge is understanding the nuances of these requirements for each situation and finding a trusted connector source to help reliably address them.

This article provides an overview of the connectivity challenges designers can expect to encounter in industrial applications. It then introduces pin and sleeve industrial plugs and sockets from Amphenol Sine Systems, showing how they facilitate safe and reliable connections and disconnections of industrial equipment.

The power connector environment

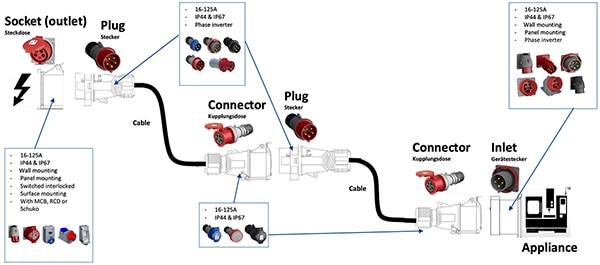

The environments in which power connectors are used can vary greatly, from cool and dry data centers to hot and humid factory floors, or even wet food processing plants. Connectors can be required to carry single-phase AC voltages, three-phase AC voltages in Wye or Delta configurations, or a range of AC and DC power. Connectors are also needed to carry power from wall-mounted power outlets to panel-mounted machine connectors (Figure 1). There may also be a need for inline plug and socket pairs to meet power configuration requirements, such as phase inversions or cable extensions.

Figure 1: The range of connector application configurations in an industrial environment includes inline, panel, and wall mount connectors. (Image source: Amphenol Sine Systems)

Figure 1: The range of connector application configurations in an industrial environment includes inline, panel, and wall mount connectors. (Image source: Amphenol Sine Systems)

Power connectors require anywhere from three to five conductors, or poles. For example, three-conductor connectors are necessary for single-phase AC power and ground. Four-conductor cables are needed for Delta-configured three-phase power, which includes the three-phase signals and a ground wire. Wye-configured three-phase power requires conductors for each phase, a neutral, and a ground, for a total of five. Conductor and connector sizes vary with the current they are rated to handle.

The connector type selected varies with its intended use. The power entry point generally requires a wall-mounted connector, while the powered device usually needs a panel-mounted connector. Of course, inline connectors join cables in between fixed terminations to allow insertion of extensions, phase inverters, or other mid-run connections.

Preventing misconnections

Designers should also consider that most installations include multiple machines; this can result in a larger number of power cables and a higher possibility of misconnections. International standards, such as IEC 60309-2 and UL/CSA, specify the connector wire/pole layout based on the type of power being carried (Figure 2), thereby minimizing the chance of incorrect connections.

Figure 2: The IEC 60309-2 or UL/CSA “clock” diagrams indicate the location of the ground pin within the connector, which codifies the configuration of the connector and its voltage rating. (Image source: Amphenol Sine Systems)

Figure 2: The IEC 60309-2 or UL/CSA “clock” diagrams indicate the location of the ground pin within the connector, which codifies the configuration of the connector and its voltage rating. (Image source: Amphenol Sine Systems)

The location of the ground pin relative to the keyway within the connector body determines the connector configuration. A ground pin can be located at any of 12 possible positions placed at 30? intervals, summarized by the “clock” diagram. It identifies each of them for three- (2P+E or 2P-3W), four- (3P+E or 3P-4W), or five- (3P+N+E or 4P-5W) cable connectors, using a color code based on the voltage rating of the connector. The conductor and, therefore, the connector diameter are matched to the rated load current.

Examples of industrial power connectors

Amphenol Sine Systems offers a comprehensive range of industrial plug and socket power connectors designed for applications that require up to 100 A and 690 V.

For example, the Amphenol Sine Systems 2CMA104446R1000 inline power connector plug, intended for three-phase Wye-connected applications, has five conductors: one for each of the three phases, one for neutral, and one for ground. It is rated to handle 200 to 415 V at 32 A (maximum). Its ground pin is located at the same 6 o’clock position as the connector keyway. The outer ring in the diagram (for five-pin connectors) at position 6, color-coded red, indicates the voltage range, in this case from 200 V to 415 V.

Connector construction

The Amphenol Sine Systems connectors use a modern, robust design (Figure 3). The connector body is composed of polybutylene terephthalate (PBT), a thermoplastic polyester. PBT is noted for superior electrical insulation, high strength, dimensional stability, and resistance to heat and chemicals. It has outstanding wear resistance, absorbs very little moisture, and is easy to machine.

Figure 3: Shown are the key features of a five-pin, 200 V to 415 V plug; the connector body is composed of PBT. (Image source: Amphenol Sine Systems, modified by Art Pini)

Figure 3: Shown are the key features of a five-pin, 200 V to 415 V plug; the connector body is composed of PBT. (Image source: Amphenol Sine Systems, modified by Art Pini)

The red hood signifies the 200 V to 415 V rating of the connector as shown in the clock diagram. The ground pin has a larger diameter than the other pins and, in this connector, based on its voltage specifications, is located at the bottom (6 o’clock position). It is also slightly longer than the others, so it makes contact first. The contact pins are made of brass and are self-cleaning when mated to the corresponding socket. The contacts are calibrated to maintain accurate contact pressure over time, ensuring quality and performance. Two stainless steel screws secure the wires to each pin. The protective sleeve enclosure around the plug pins also serves as a seal against dust and moisture. Clear terminal markings are embossed on the contact block inside the connector, indicating the phase (L1, L2, or L3), neutral (N), line (L/+), or ground (G) to minimize errors during assembly.

Cables are secured within the connector body by dual clamps: an exterior clamp at the rear and an internal clamp. A watertight grommet placed between the clamps seals the cable entry, preventing liquids from entering the connector body through the cable. Depending on the model, connectors have ingress protection ratings of IP44 (splash resistant) or IP67 (dustproof and waterproof).

The receptacle connector has a similar structure, using sockets for the contact (Figure 4).

Figure 4: Shown is a cutaway view of an inline socket connector receptacle, revealing a similar structure to the plug to maintain the integrity of the wiring. (Image source: Amphenol Sine Systems)

Figure 4: Shown is a cutaway view of an inline socket connector receptacle, revealing a similar structure to the plug to maintain the integrity of the wiring. (Image source: Amphenol Sine Systems)

The socket version of the connector incorporates the same type of seals and gaskets to protect the interior from dust and moisture. The contacts are also made of brass and feature dual locking screws to secure the wires. Additionally, the connector opening is safeguarded by a color-coded plastic cap to minimize contamination when the connector is not mated.

The Amphenol Sine Systems 2CMA166618R1000 is a five-contact receptacle connector that shares the same 32 A current and 200 V to 415 V rating as the 2CMA104446R1000 plug. With that voltage rating, its ground pin is located at the 6 o’clock position and features a red cap. Note that all connectors in this series conform to IEC 60309-1, 2, and 4, and are also approved by UL and CSA.

The receiving end of a power cable in a machine or other device typically connects through a panel-mount connector, such as the Amphenol Sine Systems 2CMA193146R1000 (Figure 5) two-pole, three-wire receptacle.

Figure 5: The 2CMA193146R1000 is an example of a two-pole, three-wire, panel-mount power receptacle. (Image source: Amphenol Sine Systems)

Figure 5: The 2CMA193146R1000 is an example of a two-pole, three-wire, panel-mount power receptacle. (Image source: Amphenol Sine Systems)

This receptacle is designed to be mounted on the outside of a device using the mounting flange. It is rated to handle 200 V to 250 V, single-phase, at 16 A. Referring to the clock diagram, the three-wire configuration (inner ring) uses a 6 o’clock setting with a blue cap. Panel-mount connectors are available in either straight or angled designs.

Connectors for the power source are usually wall-mounted. The 2CMA178699R1000 (Figure 6) wall-mounted power connector is a 4-pole, five-wire receptacle.

Figure 6: The 2CMA178699R1000 is an example of a wall-mounted industrial power receptacle. (Image source: Amphenol Sine Systems)

Figure 6: The 2CMA178699R1000 is an example of a wall-mounted industrial power receptacle. (Image source: Amphenol Sine Systems)

This flush-mount wall receptacle is rated for 380 V to 415 V and 16 A. It appears in the 6 o’clock slot in the clock diagram and has a red identification color, shown in a collar around the contact block. It has a protection rating of IP44, indicating it is splashproof. As with all socket connectors, it features a spring-loaded cover to protect the socket contacts when the connector is unmated.

Conclusion

Industrial equipment requires power connectors designed to meet the specific needs of each installation for safe, reliable, and long-lasting connections. Amphenol Sine System’s industrial plugs and sockets, available in various voltages, currents, and physical configurations, are designed to meet the specific requirements posed by the wide range of environmental conditions found in modern manufacturing, infrastructure, and data center facilities.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.