How to Use Smart Air Quality Sensors for Environmental Monitoring

Contributed By DigiKey's North American Editors

2022-10-11

Environmental monitoring using smart air quality sensors is expanding across various applications from smart homes, buildings, and cities, to conventional and electric vehicles (EVs) and battery energy storage systems (BESS). In smart homes, buildings, and cities, air quality sensors can help ensure health and safety by monitoring airborne particles and gases associated with poor air quality, as well as smoke detection for early fire warnings. In vehicle passenger compartments, these sensors can identify volatile organic compounds (VOCs) and high levels of CO2 that can raise health concerns. In EVs and BESS, they can be used to detect an increase in pressure and high levels of hydrogen in a battery enclosure following the first venting phase of a cell, enabling the battery management system (BMS) to react and prevent a second venting event or thermal runaway of the whole battery system.

The sensors used in these applications need to be compact, low power, and able to support secure boot and secure firmware updates. They often need to include multiple sensors, covering a broad spectrum of air quality monitoring. Integrating this range of functionality in a compact and low-power unit can be a daunting process, prone to restarts, resulting in a high-cost solution and delaying time to market.

To speed time to market and control costs, designers can turn to sensor modules that are factory calibrated, support secure boot and firmware updates, and provide connectivity options, including sending data to the cloud or using a CAN or other bus for local connections.

This article begins by comparing optical particulate counters, screen-printed electrochemical, and multi-parameter sensor technologies. It presents air quality sensor solutions and development platforms from Sensirion, Metis Engineering, and Spec Sensors, along with companion devices from Infineon Technologies, and includes suggestions to speed the development process.

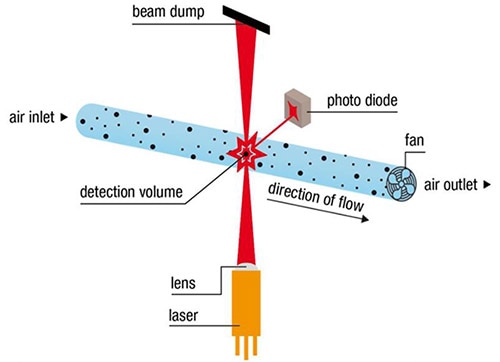

Particulate matter (PM) sensors provide counts for specific particle sizes such as PM2.5 and PM10, which correspond to particles with diameters of 2.5 microns and 10 microns, respectively, as well as other particle sizes as needed by the specific application. Optical particle counters (OPCs) are a specific PM technology that moves the air to be measured through a measurement cell that contains a laser and a photodetector (Figure 1). Particles in the air scatter the light from the laser, and the detector measures the scattered light. The measurement is converted into mass concentration in micrograms per cubic meter (μg/m3) and counts the number of particles per cubic centimeter (cm3). Counting particles using an OPC is straightforward but converting that information into a mass concentration number is more complex. The software used for the conversion needs to consider the particles’ optical parameters like shape and refractive index. As a result, OPCs can suffer from greater inaccuracy compared with other PM sensing methods such as direct, weight-based, gravimetric technologies.

Figure 1: An OPC uses a laser and photodiode to count airborne particles. (Image source: Sensirion)

Figure 1: An OPC uses a laser and photodiode to count airborne particles. (Image source: Sensirion)

Not all OPCs are the same. Highly accurate and expensive, laboratory-grade OPCs can count every particle in the measurement cell. Lower-cost commercial-grade OPCs are available that sample only about 5% of the aerosol particles and use software-based estimation techniques to arrive at an overall ‘measurement.’ In particular, the density of large particles like PM10 is typically very low, and they can’t be measured directly by low-cost OPCs.

As particle size increases, the number of particles in a given particle mass drops dramatically. Compared with an aerosol of PM1.0 particles, an aerosol with PM8 particles has about 500 times fewer particles for a given mass. To measure larger particles with the same accuracy as small particles, a low-cost OPC has to integrate data over several hours to arrive at an estimate. Fortunately, aerosols have fairly consistent distributions of small and large particles in real-world environments. With properly designed algorithms, it’s possible to accurately estimate the number of larger particles, such as PM4.0 and PM10, using measurements of PM0.5, PM1.0, and PM2.5 particles.

Amperometric gas sensors

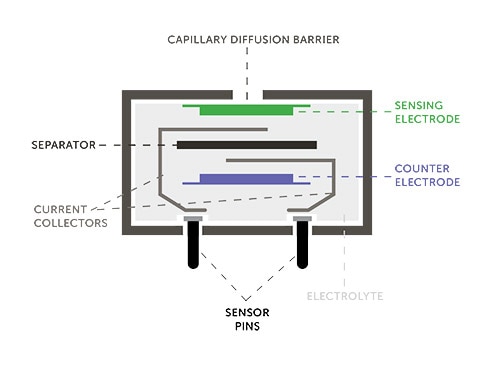

Instead of measuring particle counts, amperometric sensors measure gas concentrations. They are electrochemical devices that produce a current linearly proportional to the volumetric fraction of the gas being measured. A basic amperometric sensor consists of two electrodes and an electrolyte. Gas concentration is measured at the sensing electrode, which consists of a catalytic metal that optimizes the reaction of the gas to be measured. The gas reacts with the sensing electrode after entering the sensor through a capillary diffusion barrier. The counter electrode acts as a half-cell and completes the circuit (Figure 2). An external circuit measures the current flow and determines the gas concentration. In some designs, a third ‘reference’ electrode is included to improve the stability, signal-to-noise ratio, and speed the response time of the basic amperometric sensor.

Figure 2: Amperometric sensors use two electrodes separated by an electrolyte to measure the concentrations of gases. (Image source: Spec Sensor)

Figure 2: Amperometric sensors use two electrodes separated by an electrolyte to measure the concentrations of gases. (Image source: Spec Sensor)

Multi-parameter sensor for battery packs

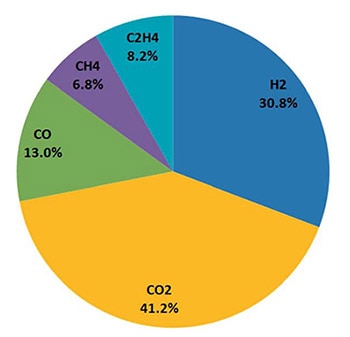

Monitoring air quality is just the start for sensors designed to protect battery packs in EVs and BESS installations. These sensors monitor pressure, air temperature, humidity, dew point, and absolute water content, in addition to volatile organic compounds (VOCs) such as methane (CH4), ethylene (C2H4), hydrogen (H2), carbon monoxide (CO) and carbon dioxide (CO2). During the first phase of battery venting, the gaseous product of a common lithium-ion battery with a nickel manganese and cobalt cathode has a known chemical composition (Figure 3). The hydrogen concentration is critical; if it approaches 4%, hydrogen’s lower explosive limit, there is a possibility of an explosion or fire. Actions should be taken to prevent the cell from going into thermal runaway. The pressure sensor can detect small increases in pressure inside a battery pack caused by venting. False positives can be avoided by cross-checking any increase in pressure with the other sensor measurements.

Figure 3: A specific mixture of gases is characteristic of the first phase of battery venting (Image source: Metis Engineering)

Figure 3: A specific mixture of gases is characteristic of the first phase of battery venting (Image source: Metis Engineering)

This multi-parameter sensor also monitors for too cool of an operating condition. Large battery packs in EVs and BESS often include active cooling to keep the packs from overheating when they are charged or discharged. If they are cooled too much, the internal temperature can drop below the dew point, resulting in condensation inside the pack, potentially shorting the cells and causing thermal runaway. The dew point sensor alerts the BMS before condensation can collect on the battery terminals.

Laser AQ sensor

Designers of heating, ventilation, and air conditioning (HVAC) systems, air purifiers, and similar applications can use Sensirion’s SPS30 PM sensor to monitor air quality indoors or outdoors. SPS sensors measure mass concentrations of PM1.0, PM2.5, PM4, and PM10, as well as PM0.5, PM1.0, PM2.5, PM4, and PM10 particle counts. It has a mass concentration precision of ±10%, a mass concentration range of 0 to 1000 μg/m3, and an operational life of over ten years. The SPS30 includes an I2C interface for short connections and a UART7 for cables longer than 20 centimeters (cm).

An automatic fan cleaning mode can be triggered at a preset interval to ensure consistent measurements. Fan cleaning accelerates the fan to maximum speed for 10 seconds and blows out accumulated dust. The PM measurement function is offline during fan cleaning. The default cleaning interval is weekly, but other intervals can be set to meet specific application requirements.

Dev kits and secure boot

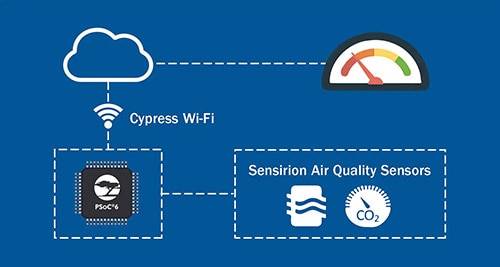

The SEK-SPS30 air quality monitor sensor evaluation board can be used to connect the SPS30 to a PC to start exploring the capabilities of this PM sensor. In addition, DigiKey offers a platform to combine Sensirion’s air quality sensors with Infineon’s PSoC 6 MCUs to develop next-generation intelligent air quality monitoring systems. For smart building systems where privacy is a concern, PSoC 6 supports secure boot and secure firmware updates (Figure 4).

Figure 4: This dev kit from Sensirion and Infineon can implement secure boot and secure firmware updates. (Image source: DigiKey)

Figure 4: This dev kit from Sensirion and Infineon can implement secure boot and secure firmware updates. (Image source: DigiKey)

Battery pack sensor

EV and BESS battery pack designers can use the CANBSSGEN1 from Metis Engineering for battery safety monitoring. It’s designed to detect early failures due to cell venting. This CAN bus-based sensor includes a replaceable air filter and is especially useful in EVs (Figure 5). An optional accelerometer can monitor for shocks up to 24G and impact duration, enabling the system to identify when the battery pack has been exposed to shocks above safe levels. It can measure:

- 0.2 to 5.5 Bar absolute pressure

- -30°C to +120°C air temperatures

- VOCs, equivalent CO2 (eCO2), and H2 in parts per billion (ppb)

- Absolute humidity in milligrams of water vapor per cubic meter (mg/m3)

- Dew point temperature

Figure 5: This battery safety monitor sensor includes a replaceable air filter (center white circle). (Image source: Metis Engineering)

Figure 5: This battery safety monitor sensor includes a replaceable air filter (center white circle). (Image source: Metis Engineering)

CAN sensor dev kit

The DEVKGEN1V1 development kit helps to shorten the system integration time when using Metis CAN sensors. The sensors include a configurable CAN bus speed and address along with a DBC CAN database that supports integration into almost any vehicle with a CAN bus. The basic dev kit can be expanded, enabling developers to add more sensors to the CAN network.

Indoor air quality sensor

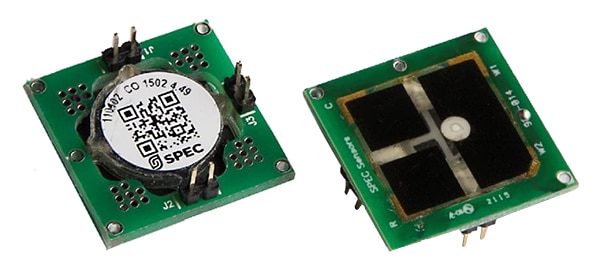

Designers of indoor and vehicle in-cabin air quality monitoring systems can use the 110-801 from SPEC Sensors. The 110-801 is a screen-printed amperometric gas sensor that can detect a broad array of gases associated with poor air quality, including alcohols, ammonia, carbon monoxide, various odorous gases, and sulfides. The response of these sensors is linearly proportional to the volumetric fraction of the gas being measured, which simplifies system integration (Figure 6). Other features of this 20 x 20 x 3 mm sensor include:

- Parts per million (ppm) sensitivity

- Less than ten microwatts (μW) sensor power

- -10°C to +40°C operating temperature range (0°C to +40°C continuous operation)

- Robust and stable operation in the presence of a wide range of contaminants

Figure 6: This screen-printed amperometric gas sensor can measure the presence of a variety of gases. (Image Source: Spec Sensors)

Figure 6: This screen-printed amperometric gas sensor can measure the presence of a variety of gases. (Image Source: Spec Sensors)

Amperometric gas sensor integration

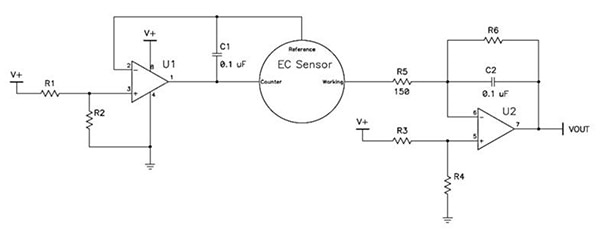

A potentiostat circuit controls the working electrode’s potential in an amperometric gas sensor and converts the electrode current to an output voltage (Figure 7). The voltage at pin 2 of the operational amplifier (op amp) U1 sets the reference electrode voltage, and the working electrode’s potential is set by pin 6 of op amp U2. Op amp U2 also converts the current output from the sensor to a voltage signal. At the same time, op amp U1 supplies current to the counter electrode that is equal to the working electrode current.

Figure 7: Simplified potentiostat circuit used to implement gas detection using an amperometric sensor. (Image source: Spec Sensors)

Figure 7: Simplified potentiostat circuit used to implement gas detection using an amperometric sensor. (Image source: Spec Sensors)

Summary

As shown, designers have a range of air quality sensor technologies to choose from when designing environmental monitoring systems. OPCs can be used to monitor for potentially dangerous particulate levels indoors and outdoors. CAN-based, multi-sensor systems can monitor for first stage venting in EV and BESS battery packs and help to prevent thermal runaway and possible fires or explosions. Low-power, screen-printed amperometric gas sensors can be used to detect a broad array of gases that cause poor air quality.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.