How to Select the Right Solid-State Relay to Match Application Requirements

Contributed By DigiKey's North American Editors

2025-04-29

Solid-state relays (SSRs) are used across an increasingly broad and varied number of industries, including plastics, packaging, food and beverage, HVAC, semiconductors, renewable and conventional energy, oil and gas, transportation, printing, laboratory, kiln and oven, lighting, medical, and motion control. SSRs are often used instead of electromagnetic relays (EMRs) because they have no moving parts and last a long time. They also are not subject to contact erosion and electrical interference due to electrical arcing at the contact surfaces.

As SSRs are available in multiple configurations that support various load types, designers must understand how to select SSRs to match the intended use. This is especially true in industrial applications such as controlling motors, pumps, and fans with their inductive loads, which require a different relay type from heating and lighting applications, which present resistive loads.

This article briefly discusses why SSRs are a good option for industrial and factory automation. It then describes their usage, characteristics, and how to select them for an application using example devices from Carlo Gavazzi.

Why use SSRs?

Industrial and factory automation systems require switching devices characterized by low cost, reliability, fast actuation times with no contact bounce or arcing, minimal electromagnetic interference (EMI), low susceptibility to harsh environments, and high mechanical shock and vibration tolerance. SSRs use semiconductor devices to replace mechanical relays' armatures and contacts in switching operations, which allows them to meet those requirements. Being completely enclosed, SSRs also resist shock, vibration, humidity, aggressive chemicals, and dust. This results in devices with long lives and high reliability.

Selecting an SSR for your application requires understanding the load being controlled and the essential characteristics of SSRs to match the application's needs to the relay specifications.

SSR control and load specifications

SSRs can be controlled using either an AC or DC control voltage. DC control uses a low voltage, typically 4 V to 32 V. They can also use a 4 mA to 20 mA current loop or a 1 VDC to 10 VDC analog input. AC control uses voltages in the range of 24 VAC to 275 VAC.

SSR loads can be either AC or DC. SSRs with maximum AC load voltages as high as 690 VAC and AC current ratings of 125 A are available. DC ratings are 500 VDC and 100 A.

Types of electrical loads

Electrical loads are classified by their dominant electrical characteristics. Motors, fans, and pumps are classified as inductive loads. The load current and voltage are out of phase, with the current lagging the voltage. Inductive loads resist changes in their load current by generating a counter voltage potential called back electromotive force (EMF). SSRs used with inductive loads need to be able to handle these voltages.

Devices like heaters, ovens, electric stoves, dryers, and lamps are examples of resistive loads. The voltage and current in resistive loads are in phase.

Capacitive loads resist changes in the load voltage. The current and voltage in a capacitive load are out of phase, with the current leading the voltage. Most switching power supplies and some medical devices like defibrillators present a capacitive load. When voltage is first applied to a capacitive load, it offers a very low impedance, resulting in a high inrush current.

The characteristics of each type of load dictate the type of SSR required to control it.

Types of SSRs

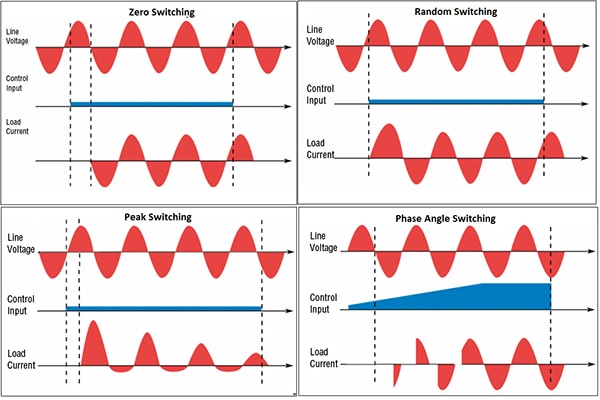

There are five commonly used types of SSRs (Figure 1): zero switching or zero crossing, instant-on or random switching, DC switching, peak switching, and phase angle or analog switching.

Figure 1: The type of SSR is determined by when the SSR switches relative to the line voltage. (Image source: Carlo Gavazzi Inc.)

Figure 1: The type of SSR is determined by when the SSR switches relative to the line voltage. (Image source: Carlo Gavazzi Inc.)

SSR types are based on when the device switches relative to the line voltage phase. The zero-switching SSR is an AC relay that switches the load at the first zero crossing of the line voltage after the control signal is applied. The switching time of the SSR is, at most, half a period of the line frequency, so for a 60 hertz (Hz) line frequency, it is 8.3 milliseconds (ms). Zero-switching SSRs are used primarily with resistive loads to limit high surge currents at the switch time. Since the line voltage is at zero when the load is connected, the current in a resistive load is also zero. This type of relay is also suitable for most inductive and capacitive loads.

The random-switching or instant-on SSR, also an AC relay, immediately delivers power to the load upon applying the control voltage. It turns on at any phase of the line voltage. The typical response delay is less than 1 ms. Random switching relays are used with inductive loads.

The DC-switching SSR is intended for DC resistive and inductive applications. Like the random switching relay, it connects the load immediately upon application of the control signal. The response time is less than 100 microseconds (ms).

The peak-switching SSR switches at the next line voltage peak after applying the control voltage. These relays are used for heavy inductive loads such as transformers.

The phase-angle or analog-switching SSR reads the voltage of the analog control signal. It varies the conduction period of the relay output proportional to the amplitude of the control voltage. This type of SSR is used in closed-loop systems and applications where a soft start is used to limit inrush currents.

Other SSR types, variants of the ones described, are used less frequently for specialized application needs.

Number of poles

SSRs are single-throw devices that can turn a pole either on or off. The number of poles refers to the number of line voltages it can control. A single-phase AC line or a DC line requires a single-pole SSR. A 220 V single-phase line needs two poles, one for each of the 110 V component sources. A three-pole relay is needed for three-phase applications.

The relays are classified as single pole single throw (SPST), double pole single throw (DPST), or triple pole single throw (3PST).

Design of SSRs

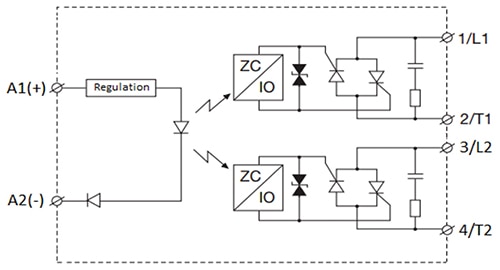

The functional block diagrams of SSRs differ depending on whether they are intended for AC or DC applications. SSRs for bipolar AC applications, such as Carlo Gavazzi’s RK2A60D50P DPST zero-switching relay (Figure 2), use thyristors as control devices.

Figure 2: Shown is the functional block diagram of the RK2A60D50P DPST SSR for AC applications. (Image source: Carlo Gavazzi Inc.)

Figure 2: Shown is the functional block diagram of the RK2A60D50P DPST SSR for AC applications. (Image source: Carlo Gavazzi Inc.)

The RK2A60D50P is rated to handle output voltages of 660 V and output currents as high as 50 A. Other SSRs in this family can handle output currents up to 75 A. It requires a control voltage of 4 VDC to 32 VDC. Like all SSRs, it uses an optocoupler to ensure electrical isolation between the control voltage source and the line of 4,000 VRMS. This relay has a common control input for both outputs; other versions in the product family have separate control inputs for each output. The assertion of the control voltage initiates a zero-crossing detector, which fires the antiparallel thyristors at the zero crossing of the line for both poles.

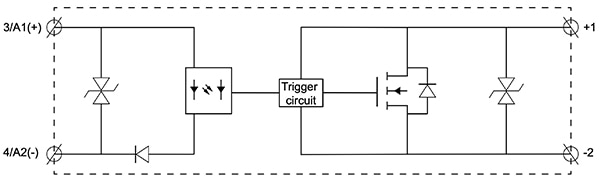

DC applications, being unipolar, use transistors as the primary switching device. This is shown in the functional block diagram of the Carlo Gavazzi RM1D060D50 SPST DC SSR (Figure 3).

Figure 3: Shown is the functional block diagram of the RM1D060D50 DC SPST SSR; DC SSRs use transistors as the primary switching device. (Image source: Carlo Gavazzi Inc.)

Figure 3: Shown is the functional block diagram of the RM1D060D50 DC SPST SSR; DC SSRs use transistors as the primary switching device. (Image source: Carlo Gavazzi Inc.)

This device handles output voltages from 1 VDC to 60 VDC and output currents of 50 A. This series of SSRs has relays that can handle 500 VDC and currents of 100 A. Because the line is unipolar DC, a MOSFET is used as the primary switch. This results in a relay with turn-on and turn-off response times that are each less than 100 ms. This relay can operate at a switching speed of 1,000 Hz and uses a DC control voltage range from 4 VDC to 32 VDC. Other devices in this product family offer AC control voltages as high as 280 V. The control voltage is also optically isolated from the line with 3750 VRMS isolation.

Galvanic isolation between the control line and the load can also be accomplished using transformer coupling. This type of isolation, shown using a block diagram of the Carlo Gavazzi RP1D060D8 (Figure 4), uses a modulated RF source coupled through an RF transformer to provide galvanic isolation between the input and output.

Figure 4: Transformer coupling in the RP1D060D8 accomplishes galvanic isolation. (Image source: Carlo Gavazzi Inc.)

Figure 4: Transformer coupling in the RP1D060D8 accomplishes galvanic isolation. (Image source: Carlo Gavazzi Inc.)

This DC switching SSR is rated to handle 350 VDC and 8 A. It uses a DC control voltage in the 4.25 VDC to 32 VDC range. It is housed in a 4-SIP package with four through-hole pins spaced on multiples of 0.1". It differs from the other SSRs cited in that it is smaller and uses transformer coupling to isolate the input from the output. It has an isolation specification of 4,000 VRMS and a switching response time of <100 ms on closure and <250 ms on opening.

Operating temperature range

SSRs switch voltages to 660 V and currents to 100 A, and can produce considerable heat. Power is dissipated when switching, where the current through the relay and voltage across it are not zero. This heat must be removed from the relay using heatsinks. The ambient temperature affects the maximum current rating of the SSR and must be derated when elevated. Typically, SSRs can be operated without a heatsink for output currents of 5 A or less. If the relay is mounted on a metal surface, that limit increases to 8 A. Carlo Gavazzi offers heatsinks matched to specific SSR models that ensure optimum performance in any thermal environment.

Mounting types

SSRs are offered in various package styles (Figure 5) to fit the intended application. Most mounting types require that the relay be secured to a heat-conducting surface or a heatsink to control the device’s temperature.

Figure 5: Shown are examples of common mounting configurations for SSRs. (Image source: Carlo Gavazzi Inc.)

Figure 5: Shown are examples of common mounting configurations for SSRs. (Image source: Carlo Gavazzi Inc.)

The Carlo Gavazzi RZ3A60D55 (left) is an AC, zero-switching, 3PST SSR with an output rated at 660 V and 55 A, controlled by a 4 VDC to 32 VDC input signal. It uses a modular chassis mounting system, with all three switching devices mounted on a common base plate. Using a thermal pad or heatsink compound, the baseplate is mounted to a heat-conducting surface.

The hockey puck SSR is so named because of its thick shape and dense construction. This package's solid structure makes it more resistant to shock and vibration, improving reliability in harsh industrial environments. The previously described RM1D060D50, shown in Figure 5 (second from left), is an example of an SSR using the hockey puck package.

The system-in-package (SIP) module is a printed circuit board (pc board) mounted enclosure for a complete electronic subsystem. The RP1D060D8 DC SSR, discussed previously and shown in Figure 5 (third from left), is mounted in a 4-SIP (four-pin) package. This SSR controls an output current of 8 A or less and can be mounted on a pc board without needing a thermal sink.

DIN rails are metal rails used inside an enclosure to mount electrical devices like circuit breakers, power supplies, and SSRs. The Carlo Gavazzi RGS1A60D50KKE is an SPST, AC, zero-switching SSR that uses DIN rail mounting and is shown on the far right in Figure 5. It can switch 660 V and 50 A at its output. It uses a DC control line with a 4 VDC to 32 VDC range. The DIN module is only 17.5 mm wide for compact installation. While the mounting rail provides some cooling, heatsinks compatible with the DIN rail are available.

Conclusion

With no moving parts and no contact erosion or electrical interference due to electrical arcing at the contact surfaces, SSRs have the reliability necessary for industrial and factory automation. Selecting the correct device can be simplified by relying on a supplier like Carlo Gavazzi, which offers an extensive range of SSR products. With some understanding of SSR operation, characteristics, and their application, designers can be more confident in finding the right relay to match a design’s requirements.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.