How to Monitor Material Levels in Tanks to Improve Supply Chain Management

Contributed By DigiKey's North American Editors

2023-03-08

Sensing and measuring the amount of solid, fluid, or granulated materials stored in tanks has become increasingly important due to supply chain challenges and the need to monitor inventory levels and control manufacturing processes closely. Depending on the application, level sensors can be required to be food-safe, withstand high pressures, temperatures, or vibrations, be used in corrosive environments with high resistance to acids and bases, and have a high degree of electrical and thermal isolation to ensure safe operation.

While it’s possible to design level sensors, it’s a complex task fraught with risk. The process begins with matching the measurement technology, such as capacitive, magnetic, ultrasonic, or optical sensing, with the application. The next step is selecting the housing, components, and other materials to support the operating environment. It’s also often necessary to gain safety and regulatory approvals and ensure that the design achieves the required ingress protection (IP) rating.

Instead, designers can turn to pre-engineered level sensing solutions that ensure accurate and reliable measurements and speed time to market. This article begins with a review of the operation of capacitive, magnetic, ultrasonic, and optical sensing technologies, including form A (normally open) and form B (normally closed) devices. It then looks at materials’ suitability and IP ratings and identifies the best-suited applications for each technology. It then presents examples of level sensors using magnetic, capacitive, ultrasonic, and optical sensing from PIC, Carlo Gavazzi, and TE Connectivity.

Magnetic liquid level sensors, also called float sensors, use a reed switch in a sealed stem with a float containing a ring magnet. As the liquid level rises and falls, so does the float with the magnet. When the ring rises (or falls) to a certain level, it activates the reed switch (Figure 1). These designs are highly reliable and rated for millions of switching actuations in Form A and Form B configurations. They are available with various housing materials like polypropylene, polyamide, and stainless steel suited for various liquids, and some are food safe. Models are available for top, bottom, and side mounting.

Figure 1: When the float in a magnetic liquid level sensor rises (left) or falls (right), it activates a reed switch that sends out a signal. (Image source: PIC)

Figure 1: When the float in a magnetic liquid level sensor rises (left) or falls (right), it activates a reed switch that sends out a signal. (Image source: PIC)

Capacitive sensing for liquids and more

In addition to sensing liquid levels in tanks, capacitive-level sensors can be used with solids or granular materials. The probe combines with the tank wall to form a capacitor. The capacitance varies with the amount of material in the tank. Typically, the more material in the tank, the higher the capacitance. These sensors are available with various housing materials. Capacitive level sensors can include adjustable sensing distances and are designed with and without a built-in time delay for turning on or off. They can be used with a wide range of liquids and solids and are commonly found in industrial processes and agricultural applications such as automated livestock feeding systems and silos (Figure 2).

Figure 2: Agricultural applications like measuring granular livestock feeds commonly use capacitive level sensors. (Image source: Carlo Gavazzi)

Figure 2: Agricultural applications like measuring granular livestock feeds commonly use capacitive level sensors. (Image source: Carlo Gavazzi)

Ultrasonics for high pressures and aerated liquids

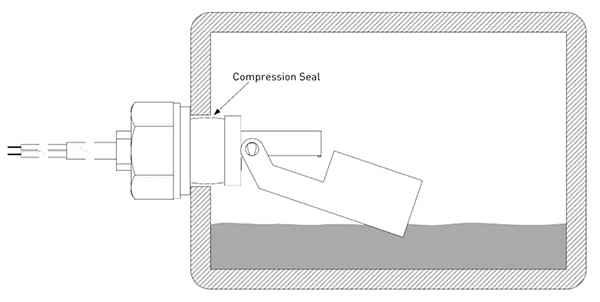

Ultrasonic level sensors typically operate in the range of 40 kilohertz (kHz), well beyond the range of human ears. They use bursts of ultrasonic energy sent across a gap. When a liquid is present, the transmission of the ultrasonic energy is enhanced; when only air is present, the energy is attenuated. These gap sensors provide point-level sensing for various liquids and are especially suitable for use with aerated liquids that can be challenging to monitor with other technologies. Typical designs of these sealed sensors are rated for operation in pressurized liquids up to 250 pounds per square inch (PSI), but special designs can operate up to 5,000 PSI (Figure 3).

Figure 3: Ultrasonic level sensors can be sealed and operated under high pressures. (Image source: TE Connectivity)

Figure 3: Ultrasonic level sensors can be sealed and operated under high pressures. (Image source: TE Connectivity)

Seeing levels with optical sensors

Optical level sensors operate based on different refractive indices between air and the liquid being monitored. They consist of an infrared (IR) emitter (the transmitter), a receiver, an amplifier, and an output switch. The emitter is typically a gallium arsenide (GaAs) infrared emitting diode. The output can be a transistor for direct current (DC) outputs or an SCR for alternating current (AC) outputs. The conical tip of the sensor forms a prism with the IR pulses transmitted down to the tip and, when no liquid is present, internally reflected to the receiver. When the sensor’s tip is immersed, the liquid will have a refractive index different from the air, and the beam will not be transmitted to the receiver (Figure 4). Optical level sensors are quite versatile and can be used in oil, wastewater, and alcohol, as well as food solutions like beer, wine, and brewed coffee.

Figure 4: Optical level sensors use the different indices of refraction of air (left) and liquid to interrupt the transmission of the signal to the receiver (right). (Image source: Carlo Gavazzi)

Figure 4: Optical level sensors use the different indices of refraction of air (left) and liquid to interrupt the transmission of the signal to the receiver (right). (Image source: Carlo Gavazzi)

Housing matters

The housing material is a key element determining where various level sensors can be used. Some of the common housing materials include:

Polyesters have excellent resistance to many chemicals and high resistance to cracking. They can be used from -70°C to +150°C.

Stainless steel is compatible with various chemicals and food products. It has excellent biological cleanability and is often used in pharmaceutical and food processing as well as medical and industrial applications.

Polyamide 12, also called Nylon 12, has high transparency, good toughness, even at low temperatures, dimensional stability, and dynamic strength, and is lightweight due to its low density. It can be used up to 80 °C.

Polysulfones are high-strength, transparent, and versatile. They have high dimensional stability; the size change is below 0.1% when exposed to boiling water or 150 °C steam or air. They are highly resistant to electrolytes, alkalis, and acids from pH 2 to pH 13. Resistance to oxidizing agents means it can be cleaned using bleaches.

Polypropylene is resistant to many organic solvents, acids, and alkalis but susceptible to attack from oxidizing acids, chlorinated hydrocarbons, and aromatics. It has a maximum operating temperature of 80 °C. It’s highly impermeable to water, making it well-suited to immersion applications.

IP ratings

IP rating codes are set in IEC 60529 and included in ANSI 60529 in the US and EN 60529 in Europe. They consist of two numbers, with the first indicating the resistance to ingress of solid objects on a scale of 0 to 6 and the second indicating protection from liquids on a scale from 0 to 9K. Lower IP ratings are not especially relevant to applications where level sensors are found. Some of the higher levels of solid object ingress include:

5 – indicates dust protection. Ingress of dust is not entirely prevented. But the equipment should continue operating, even if at a lower performance level, in the presence of dust.

6 – indicates dust tight. Ingress of dust is eliminated.

The second number for the ingress of liquids is more complex. The higher performance categories include:

7 – Immersion, up to 1 meter (3 feet, 3 inches) for a defined pressure and duration will not result in the ingress of water in a harmful quantity.

8 – Continuous immersion up to 1 meter (3 ft 3 in) or more depth under conditions specified by the manufacturer.

9K – Provides protection from close-range high pressure, high-temperature spray downs.

FDA-approved magnetic level sensors

For applications needing US Food and Drug Administration (FDA) approval, designers can turn to magnetic level sensors in polypropylene housings from PIC. The PLS-020A-3PPI is a compact sensor for vertical measurements, while the PLS-092A-3PPH is designed for horizontal sensing (Figure 5). These level sensors have an IP67 rating and form A contacts rated for a maximum of 10 watts (W), 0.7 amperes (A), 180 volts direct current (VDC), and 130 volts alternating current (VAC). They have an operating temperature range of -20 to +80 °C.

Figure 5: The PLS-092A-3PPH is a horizontal magnetic level sensor with FDA approval. (Image source: PIC)

Figure 5: The PLS-092A-3PPH is a horizontal magnetic level sensor with FDA approval. (Image source: PIC)

Capacitive sensors

Capacitive sensors from Carlo Gavazzi in thermoplastic polyester housing are available with adjustable sensing distances and with (VC11RTM2410M) or without (VC12RNM24) a built-in time delay. For sensors with a time delay, the delay can be up to 10 minutes for form A or form B actions. These sensors have an adjustable sensing distance of 4 to 12 mm and can be used for monitoring a variety of solid, liquid, and granulated materials. The single pole double throw (SPDT) relay output can directly drive loads such as solenoids and actuators. These sensors operate with supply voltages of 20.4 to 255 VAC or VDC and are rated for temperatures from -20°C to +70°C

Level sensor with high repeatability

The LL01-1AA01 ultrasonic level sensor from TE Connectivity features repeatability of 2 mm or better using digital filter techniques to improve performance. It has a single pole single throw (SPST) relay output in either form A or B. Packaged in a stainless-steel housing, this sensor is rated for 5.5 VDC to 30 VDC input and can support peak load voltages of 100 VAC or VDC with a continuous current of 3.5 A up to +25°C, derating linearly to 0.75 A at +100°C. It can handle pressures up to 250 PSI. Options include a maximum operating temperature of 80 or 100 °C, ¼” NPT or ½” NPT mounting, and cable lengths of 1, 4, 10, and 20 feet.

Optical sensors in a choice of housing materials

The VP01/02 optical level sensors, like the VP01EP from Carlo Gavazzi, are in a polysulfone housing resistant to most acids and bases. The company’s VP03/04 sensors, like the VP03EP, are in a polyamide 12 housing resistant to various solvents. These IP67-rated sensors can be used in ambient light levels up to 100 lux. Form A and form B output choices include NPN/PNP transistors for dc loads or an SCR for ac loads. DC-powered sensors have an optical pulse frequency of 30 Hertz (Hz), while AC-powered sensors have a 5 Hz pulse frequency. DC-powered sensors operate from 10 VDC to 40 VDC and have an LED that indicates that the output is ON. AC-powered sensors are rated for 110 VAC or 230 VAC nominal inputs.

Figure 6: These optical level sensors are available in a choice of polysulfone and polyamide 12 housings. (Image source: Carlo Gavazzi)

Figure 6: These optical level sensors are available in a choice of polysulfone and polyamide 12 housings. (Image source: Carlo Gavazzi)

Conclusion

Various sensing technologies, including magnetic, capacitive, optical, and ultrasonic, are available to monitor the amount of fluid, granulated, and solid materials stored in tanks, help monitor inventory levels, and control manufacturing processes. These sensors are available in various housing materials suited to specific operating environments, including high temperatures, high pressures, and sterilization processes.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.