How to Implement Condition-Based Monitoring Using Single-Pair Ethernet

Contributed By DigiKey's North American Editors

2023-12-13

In factory automation and the Industrial Internet of Things (IIoT), condition-based monitoring (CbM) provides insight into asset health to increase uptime and productivity, decrease maintenance costs, extend asset life, and ensure worker safety. While improvements in sensors, diagnostic algorithms, processing power, and the application of artificial intelligence (AI) and machine learning (ML) techniques are making CbM more useful, a lack of suitable infrastructure has limited its reach across many applications.

Equipment in applications for mining, oil/gas, utilities, and manufacturing, is often situated in locations that lack power or data networks. Running new power and network cables to these remote locations can be costly and impractical, especially for the CbM applications that require relatively high power and data rates.

Wireless alternatives come with tradeoffs. For example, a battery-powered sensor can only offer limited data rates, making these setups unsuitable for CbM. To bring the latest CbM capabilities to these locations, engineers need alternative infrastructure options that deliver reliable power and high-bandwidth networking at a low cost.

10BASE-T1L single-pair Ethernet (SPE) was explicitly designed to meet these criteria. It provides data and power over distances up to 1 kilometer (km), far beyond the limitations of Industrial Ethernet. Engineers can deploy sophisticated CbM technology to previously inaccessible locations with this new technology.

This article provides an overview of CbM and the impact of AI before outlining the advantages of SPE for remote locations. It highlights critical components of SPE-based sensors and offers guidelines for choosing them. Finally, the article reviews the basics of designing a combined data and power communication interface, and it shows how to integrate an SPE-based CbM system into a broader industrial network.

CbM and the impact of AI and ML

While many factors are propelling the growth of CbM, the rise of AI and ML is particularly noteworthy. These technologies are extending the reach of CbM beyond rotating equipment such as pumps, compressors, and fans, to encompass a broader spectrum of machinery that includes CNC machines, conveyor systems, and robotics.

These advances are possible thanks to the ability of AI and ML systems to ingest and interpret myriad data, including vibration, pressure, temperature, and visual data. With rich data sets, AI and ML systems can identify abnormal behaviors that older technologies might have missed.

To achieve these benefits, high-fidelity data must be available from all relevant equipment, which is why it has become critical for CbM systems to provide edge-to-cloud connectivity to the most far-flung corners of an operation (Figure 1).

Figure 1: Modern CbM systems must connect far-flung operations technology (OT) equipment with information technology (IT) systems. (Image source: Analog Devices)

Figure 1: Modern CbM systems must connect far-flung operations technology (OT) equipment with information technology (IT) systems. (Image source: Analog Devices)

The advantages of SPE over the alternatives

To serve these remote locations, engineers need an IT-friendly way to deliver data and power that keeps cost and physical footprint to a minimum. Industrial Ethernet solutions are an obvious choice as they offer a typical data bandwidth of 100 megabits per second (Mbps), and Power over Ethernet (PoE) up to 30 watts per port. However, Industrial Ethernet is constrained to a distance of 100 meters (m).

Enter SPE, which, as the name implies, provides Ethernet connectivity over a single twisted pair of wires, instead of two pairs for 100BASE-TX or four pairs for 10BASE-T. As a result, SPE cabling is smaller, lighter, and less costly than equivalent Industrial Ethernet cabling. Despite the reduced footprint, SPE supports runs of up to 1 kilometer (km), data rates up to 1 gigabit per second (Gbps), power up to 50 watts, and connectors rated to IP67 for harsh environments.

It is worth noting that the maximum ratings for SPE are mutually exclusive. For example, 1 Gbps speeds are only supported for short runs up to 40 m. In contrast, data rates are limited to 10 Mbps at the maximum cable length of 1 km.

How to select an Ethernet MAC for use in an SPE application

Like all Ethernet connections, SPE interfaces incorporate a media access control (MAC) layer and a physical (PHY) layer. The MAC manages Ethernet traffic, while the PHY transforms analog waveforms from the cable into digital signals.

Many advanced microcontroller units (MCUs) are equipped with a MAC, and some include a PHY. However, the low-cost, low-power MCUs used for edge sensors lack either of these features. The solution lies in the 10BASE-T1L MAC-PHY, which implements both elements in a separate chip, enabling designers to choose from various ultra-low-power processors.

A good example is the ADIN1110CCPZ-R7 from Analog Devices (Figure 2). This single-port 10BASE-T1L transceiver is designed for extended reach, 10 Mbps SPE connections. The ADIN1110 connects to the host via a 4-wire serial peripheral interface (SPI), an interface found on most modern microcontrollers.

Figure 2: The ADIN1110 is a single-port 10BASE-T1L transceiver that connects to the host processor via a 4-wire SPI interface. (Image source: Analog Devices)

Figure 2: The ADIN1110 is a single-port 10BASE-T1L transceiver that connects to the host processor via a 4-wire SPI interface. (Image source: Analog Devices)

To improve robustness, the ADIN1110 has integrated voltage supply monitoring and power-on-reset (POR) circuitry. Furthermore, programmable transmit levels, external termination resistors, and independent receive and transmit pins make the device suitable for intrinsic safety applications.

Designing a shared data and power communications interface

SPE provides power and data over the same wires using a technology called Power over Data Lines (PoDL). As illustrated in Figure 3, high-frequency data is coupled to the twisted pair through series capacitors, while direct current (DC) power is coupled to the lines using inductors.

Figure 3: PoDL provides power and data signals over a single twisted pair using inductive and capacitive coupling, respectively. (Image source: Analog Devices)

Figure 3: PoDL provides power and data signals over a single twisted pair using inductive and capacitive coupling, respectively. (Image source: Analog Devices)

In practice, additional components are required for robustness and fault tolerance. For example, a bridge rectifier diode is recommended to protect against incorrect polarity of the power connection. Similarly, a transient voltage suppressor (TVS) diode is required for electromagnetic compatibility (EMC) robustness. Notably, a choke is needed to mitigate common-mode noise from the cable.

Selecting sensors for CbM

As noted earlier, CbM can apply to a wide variety of sensing modalities. Across these modalities, one of the critical factors to consider is the trade-off between performance and efficiency.

Take vibration sensing as an example. Piezoelectric sensors offer superior performance to microelectromechanical systems (MEMS) but at a higher cost. This makes piezoelectric sensors a good choice for highly critical assets, which tend to be centrally located.

In contrast, many less-critical assets are often located in the farthest reaches of a facility and are, therefore, not currently monitored due to cost constraints. Yet their data must still be mined to improve overall system productivity. The distance and cost sensitivity combination is exactly where SPE-based CbM excels, making MEMS sensors a natural fit.

Along with lower cost, MEMS sensors offer other advantages for SPE sensors. For example, compared to piezoelectric sensors, most MEMS sensors offer digital filtering, excellent linearity, low weight, and small size.

The next design choice is between single and triple-axis sensors. Table 1 notes the difference between two typical examples, the ADXL357BEZ-RL triple-axis accelerometer and the ADXL1002BCPZ-RL7 single-axis accelerometer.

|

Table 1: Single-axis ADXL1002BCPZ-RL7 and triple-axis ADXL357BEZ-RL sensors offer tradeoffs across many important areas of consideration. (Image source: Analog Devices)

As Table 1 demonstrates, single-axis sensors offer considerably higher bandwidth and lower noise. However, triaxial sensors can capture vertical, horizontal, and axial vibrations, offering a more detailed understanding of an asset’s operation. Many faults, including bent shafts, eccentric rotors, bearing issues, and cocked rotors, are challenging to identify with a single-axis sensor.

It is worth noting that vibration sensors alone cannot detect all faults, even those primarily related to vibration. In some scenarios, the optimal solution may be to pair a single-axis sensor with other sensors, like a sensor for a motor’s current or magnetic field. In other cases, the best solution may involve two or more single-axis sensors.

Given the complexity of these considerations, it is advisable to experiment with both types of sensors. To this end, Analog Devices offers the ADXL357 3-Axis Sensor Evaluation Board and the ADXL1002 1-Axis Sensor Evaluation Board.

Integrating an SPE-based CbM system into a larger industrial network

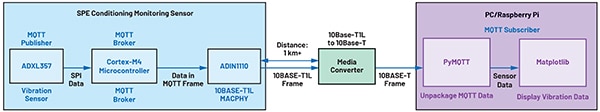

An essential requirement for any CbM system is to provide seamless connectivity back to the cloud. Figure 4 illustrates how this can be accomplished using the Message Queuing Telemetry Transport (MQTT) protocol. This lightweight IIoT messaging protocol enables connection of remote devices with a minimal code footprint and low network bandwidth.

Figure 4: Shown is a CbM architecture based on SPE. Key sensor system components include the sensor, a low-power edge processor, and the MAC-PHY. (Image source: Analog Devices)

Figure 4: Shown is a CbM architecture based on SPE. Key sensor system components include the sensor, a low-power edge processor, and the MAC-PHY. (Image source: Analog Devices)

Most low-cost Cortex-M4 microcontrollers are suitable for this application, as virtually all these chips will have the SPI ports needed to connect to the sensor(s) and MAC-PHY. From a software perspective, the main requirements are sufficient memory for the MQTT stack, an appropriate real-time operating system (RTOS), and edge analytics software. Typically, only a few tens of kilobytes of RAM and ROM are needed.

Once the SPE cable reaches the existing infrastructure, a media converter can change the 10BASE-T1L signal into 10BASE-T frames for standard Ethernet cables. Note that this conversion merely changes the physical format; the Ethernet packets remain untouched. From here, these packets can be sent across any Ethernet network.

Conclusion

SPE is emerging as a transformative technology, adeptly addressing the challenges of CbM for remote equipment. Its PoDL capabilities elegantly merge power and data transmission over a single twisted pair, providing a low-cost way to extend Ethernet infrastructure to greater distances. With the thoughtful selection of MAC-PHY interfaces and MEMS sensors, engineers can use these capabilities to deploy compact, lightweight solutions that are sufficiently cost-effective to justify their use on less critical assets. This enables new levels of visibility into operations that AI and ML systems can use to provide unprecedented operational insights.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.