How to Design Effective Power Supply Thermal Management in Industrial and Medical Systems

Contributed By DigiKey's North American Editors

2022-08-25

Efficient and cost-effective thermal management for power supply units (PSUs) is important when designing industrial and medical systems to ensure reliability. Designing an effective thermal management system for a PSU is a complex activity, and much depends upon whether the PSU is enclosed or open frame.

If an enclosed PSU is used, the type of enclosure has an impact on airflow and thermal dissipation. While fans help, designers need to consider fan reliability as well as the back pressure caused by system fans that can significantly reduce the effectiveness of the PSU fan(s), potentially increasing PSU operating temperatures.

PSUs often have lower efficiencies at low input line voltage conditions. As a result, units that are operated for extended periods under low input line conditions can result in higher thermal dissipation and the need for additional cooling. Finally, PSUs often require derating if operated at elevated temperatures that can be experienced in industrial and medical systems.

To speed the implementation of effective thermal management systems, designers can turn to PSUs specifically designed for use in industrial and medical applications that offer a range of thermal management options.

This article reviews the thermal management challenges when designing industrial and medical systems and offers guidance for designing effective thermal management solutions. It then presents options when integrating PSUs into industrial and medical equipment using PSUs from Bel Power Solutions as real-world examples, and closes with some practical steps designers can follow when integrating a PSU into the overall system thermal design.

Power supply thermal management challenges

PSU thermal management challenges include system airflow and the impact that system fans can have on the performance of any fans integrated into PSUs, the ambient operating temperature, the need for peak power delivery, and the impact the input voltage range can have on power dissipation. These are first-order considerations; this article does not touch on second-order thermal management considerations related to rack mount systems or special environments such as data centers.

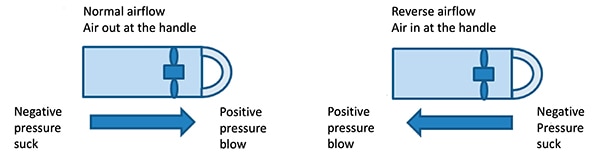

One of the first considerations is the direction of PSU airflow; normal airflow creates positive pressure exiting the system and reverse airflow creates positive pressure entering the system (Figure 1).

Figure 1: In normal airflow, positive pressure exits the system (left). With reverse airflow, positive pressure enters the system (right). (Image: Bel Power Solutions)

Figure 1: In normal airflow, positive pressure exits the system (left). With reverse airflow, positive pressure enters the system (right). (Image: Bel Power Solutions)

A fan is not enough

Many PSUs include a cooling fan. Rather than simplifying the thermal design, a PSU with a fan can complicate thermal design with considerations of airflow direction as well as the system or chassis airflow impedance and pressure. Complications include:

- System fans can compete with and reduce the effectiveness of PSU fans, reducing airflow through the PSU.

- The entry to the PSU fan can have an unexpectedly high impedance, reducing airflow through the PSU.

- Cables or other obstacles can block the PSU airflow, reducing the effectiveness of the fans.

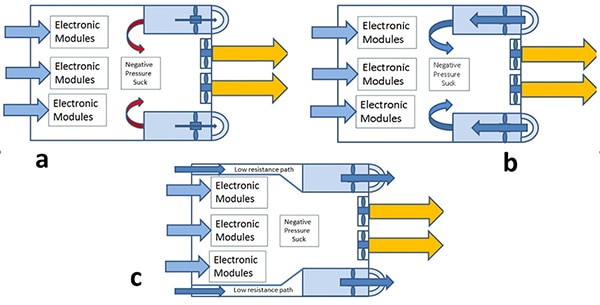

There are several ways that system and PSU fans can interact, examples are shown in Figure 2 below:

- The PSU fan(s) produce normal airflow, but the higher performance of the system fan(s) results in a lower (negative) pressure inside the chassis, thereby reducing PSU fan effectiveness.

- The PSU fan(s) produce reverse airflow and the system fan(s) are helping the PSU cooling, not fighting it. However, if the air entering the PSU is coming from the system exhaust plenum, that can create issues that include a reduction in net airflow, as well as recirculation issues that cause the accumulation of heat in the PSU.

- The air entry to the PSU is isolated from the main chassis airflow protecting the PSU fans from interference from the system fan(s). To realize the maximum benefit, the airflow channel for the PSU should have a low resistance.

Figure 2: Thermal design must take into consideration the direction of airflow in the PSU and the relative strengths of the PSU and system fans. (Image source: Bel Power Solutions)

Figure 2: Thermal design must take into consideration the direction of airflow in the PSU and the relative strengths of the PSU and system fans. (Image source: Bel Power Solutions)

Peak vs. nominal power rating and derating

Derating is often different for peak power versus nominal power. Peak power needs vary widely from a few milliseconds (ms) up to 10 seconds or more, and it’s an important consideration in many industrial and medical systems. Consider two 600-watt PSU series optimized for different peak power delivery; the ABC601 series of industrial and medical AC-DC power supplies from Bel Power Solutions that is rated for 10 seconds of peak power delivery, and the VPS600 series that’s rated for 1 ms of peak power.

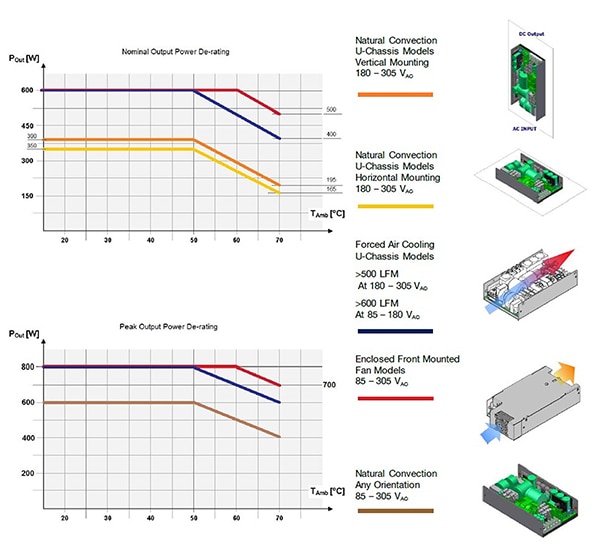

The ABC601 series provides up to 600 watts of regulated output power over an input voltage range from 85 to 305 volts alternating current (VAC) in single outputs of 24, 28, 36, or 48 volts direct current (VDC). For example, the ABC601-1T48 has a 48 VDC output. These PSUs are rated for 600 watts of continuous power or peak power up to 800 watts for up to 10 seconds at up to 60°C for the enclosed front-mounted fan models (Figure 3). They have a 5 VDC standby power output rated for 1.2 amperes (A) for U chassis models and 1.5 A for front-mounted fan models, and a 12 volt, 1 A, fan output.

Figure 3: The enclosed front-mounted fan models of the ABC601 series deliver 600 watts of continuous power (red line on top graph) or up to 800 watts for up to 10 seconds (red line on bottom graph) at up to 60°C. (Image source: Bel Power Solutions)

Figure 3: The enclosed front-mounted fan models of the ABC601 series deliver 600 watts of continuous power (red line on top graph) or up to 800 watts for up to 10 seconds (red line on bottom graph) at up to 60°C. (Image source: Bel Power Solutions)

The ABC601 series comes in two packages, U-frame chassis or enclosed with a front-mounted fan (Figure 4). The ABC601 series features an internal current share circuit for parallel operation between units to enhance total power.

Figure 4: ABC601 PSUs are available with fan cooling (top) or convection cooling (bottom). (Image source: Bel Power Solutions)

Figure 4: ABC601 PSUs are available with fan cooling (top) or convection cooling (bottom). (Image source: Bel Power Solutions)

The EOS Power VPS600 series of open frame PSUs from Bel Power Solutions feature a narrower input range of 85 to 264 VAC and deliver up to 600 watts of continuous output power and peak power of 720 watts for 1 ms (Figure 5). These PSUs are available with output voltages of 12, 15, 24, 30, 48, and 58 VDC. For example, the VPS600-1048 has an output of 48 VDC. These units include a 5 VDC, 500 milliamperes (mA), standby power output and a 12 volt, 500 mA, fan output. While the ABC601 series is offered in two package styles, the VPS600 series is available in three with different power ratings: convection cooled U channel rated for 600 watts, slotted cover units rated for 420 watts, and plain cover units rated for 360 watts.

Figure 5: The VSP600 series is available in three package configurations with different nominal power ratings; 600-watt convection cooled U channel units, 420-watt slotted cover units, and 360 watt plain cover units. (Image source: Bel Power Solutions)

Figure 5: The VSP600 series is available in three package configurations with different nominal power ratings; 600-watt convection cooled U channel units, 420-watt slotted cover units, and 360 watt plain cover units. (Image source: Bel Power Solutions)

The various output voltage options and package styles have different derating curves. For example, the derating for 24 VDC output units is:

- Open frame

- Convection load, 600 watts continuous up to 30°C

- Slotted cover

- Convection load, 420 watts continuous up to 30°C

- Plain cover

- Convection load, 360 watts continuous up to 30°C

- For all cover styles

- Derate between 30 and 50°C by 0.833% per °C

- Derate above 50°C by 2.5% per °C to a maximum of 70°C

The input voltage effect

PSU efficiency can be reduced at lower input voltages, resulting in derating of the nominal output power. For example, the ABE1200/MBE1200 series of AC-DC power supplies provide 1200 watts with an input of 180 to 305 VAC, and 1000 watts with an input range of 85 to 180 VAC (Figure 6). These nominal ratings are from 0 to 60°C. At 70°C, they derate linearly from 1200 to 1100 watts and from 1000 to 900 watts, respectively.

Figure 6: The ABE1200/MBE1200 PSUs deliver 1200 watts with input voltages from 180 to 305 VAC and 1000 watts with input voltages from 85 to 180 VAC. (Image source: Bel Power Solutions)

Figure 6: The ABE1200/MBE1200 PSUs deliver 1200 watts with input voltages from 180 to 305 VAC and 1000 watts with input voltages from 85 to 180 VAC. (Image source: Bel Power Solutions)

These PSUs include a fan speed control to minimize audible noise when maximum airflow is not needed. They are available in three 1U height compatible packages, including an enclosed model with two fans (24 VDC models only), and a U-shaped chassis with two protective cover options (Figure 7).

Figure 7: The ABE1200 PSUs are available with dual fans (24 VDC models only), and two choices of protective covers. (Image source: Bel Power Solutions)

Figure 7: The ABE1200 PSUs are available with dual fans (24 VDC models only), and two choices of protective covers. (Image source: Bel Power Solutions)

DIN is different

The LEN120 series PSUs have a nominal power rating of 120 watts and are designed for standard DIN-rail mounting. For example, the LEN120-12 delivers an output of 12 VDC over nominal input voltage ranges of 90 to 264 VAC (universal) or 127 to 370 VDC (Figure 9). When derating DIN-rail PSUs, the datasheets often simultaneously consider input and output voltages, in addition to the operating temperature. For the LEN120 series:

- All models

- From -20°C to -10°C, with a nominal 115 VAC input, output power derates 2%/°C

- From -20°C to -10°C, with a nominal 230 VAC input, no derating is required

- From +40°C to +60°C, with a nominal 115 VAC input, output power derates 2.5%/°C

- For input voltages between 115 and 264 VAC and between 162 and 370 VDC, no derating is required

- For input voltages between 115 and 90 VAC and between 162 and 127 VDC (low line conditions), output power derates 1%/V

- Model LEN120-12 (12 VDC output)

- From +45°C to +60°C, with a nominal 230 VAC input, output power derates 3.33%/°C

- Models LEN120-24 and LEN120-48 (24 and 48 VDC output, respectively)

- From +50°C to +60°C, with a nominal 230 VAC input, output power derates 5%/°C

Figure 8: The LEN120 series DIN-rail PSUs are rated 120 watts and are convection cooled. (Image source: Bel Power Solutions)

Figure 8: The LEN120 series DIN-rail PSUs are rated 120 watts and are convection cooled. (Image source: Bel Power Solutions)

Practical steps toward better thermal designs

As shown, the integration of a PSU into a system involves complex thermal design issues. There are several practical steps designers can follow to help avoid unpleasant surprises:

- The PSU maker can provide detailed information on the relationship between fan air flow and static pressure (the P-Q curve), enabling designers to know what airflow to expect if the PSU fan will be operating with or against internal back pressure in the system.

- Some PSU makers can supply FlowTHERM thermal models of the PSU that can be used in the overall system model to assess PSU thermal performance and identify potential concerns.

- Have the PSU maker review a system thermal design and make recommendations for further analysis, or confirm the validity of the design.

Conclusion

There are several issues to consider when designing a PSU thermal management system for medical or industrial applications. They include system airflow, the impact that system fans can have on the performance of any fans integrated into the PSU, the specified operating temperature range, the need to support peak power delivery, and the impact the input voltage range can have on power dissipation.

To help solve these issues, designers can turn to PSU designs from Bel Industrial Power that are optimized for different thermal environments and application scenarios. Additionally, thermal management tools are available from PSU makers that can help speed the design process.

Recommended Reading

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.