How to Accurately Monitor and Control Gas Flow in Industrial Applications

Contributed By DigiKey's North American Editors

2022-01-04

Many industrial automation (IA) and manufacturing facilities often require the use of gases such as air, oxygen, nitrogen, hydrogen, helium, and argon for various processes and applications. These uses include cleaning, cutting, welding and chemical manufacturing. In many cases, precision equipment and chemical processes require extremely fine control of gas to avoid difficult-to-diagnose equipment malfunctions or failed processes. Also, excess gas flow can result in loss of efficiency, along with the extra costs associated with gas container replacement.

Precise gas flow, measured in standard liters per minute (SLM), is an interesting problem since measurement accuracy is affected by pressure and temperature, as well as the accuracy of the sensing mechanism. Standard mass flow controllers are commonly used to control gas flow, but these can lose accuracy over time and require periodic calibration while still in service, thereby adding to lifetime cost. Technological advances have led to the use of microthermal measurement of gas temperatures to accurately determine the precise SLM volume flow.

This article discusses the importance of industrial gases and the problems resulting from inaccurate gas flow control. It then looks at mass flow controllers from Sensirion with advanced gas flow sensing technology and explains how to set up and use them effectively to lower overall cost while improving efficiency, reliability, and productivity.

Industrial gases need precise control

Industrial facilities use a variety of gases for various uses based on the properties of the individual gases. Some systems, such as heating, ventilation, and air conditioning (HVAC) systems can be forgiving of small errors in gas flow control, but precision equipment such as chemical vapor deposition (CVD), gas and liquid chromatography, and mass spectrometry require extremely precise control of gases to avoid equipment malfunctions or failed processes. These types of malfunctions are difficult to diagnose and can result in lengthy and expensive downtime.

Flammable gases such as hydrogen, acetylene, and butane are mixed with oxygen to create heat, flame, or a controlled explosion. The gases must be mixed together in the proper concentration for the process. Just like in an automobile’s internal combustion engine, a mixture of flammable gas that is too lean or too rich can produce a flame that is the improper temperature, resulting in an inefficient or failed process.

Compressed gases such as oxygen, nitric oxide, and air are used as oxidizing agents, and also to assist with combustion. Too little compressed gas can result in a failed chemical process, while too much gas results in lost efficiency, wasting gas, and increasing cost.

Inert gases such as argon, carbon dioxide, and nitrogen are often used for critical safety operations such as fire or oxidation control, and also to suppress some chemical reactions. Too little gas can result in a failed fire suppression activity, while too much wastes gas and increases related costs.

Controlling gas flow with industrial mass flow controllers

Mass flow controllers are used to meter out the proper volume of gas. In their simplest form, mass flow controllers are completely manual and do not require a power supply. The volume of gas is adjusted by turning a dial to the proper setting. However, manual mass flow controllers only measure volume at ambient temperature and cannot account for changes in volume due to pressure or temperature changes of the gas. For this reason, electronic mass flow controllers are used for precision control of gasses.

The SLM unit of measurement for volume flow of industrial gases is defined as one liter of gas flow over one minute at a standard gas temperature of 0°C/32°F and a standard gas absolute pressure of 1 bar. The volume of any gas varies based on temperature and pressure, so the mass flow controller needs to be able to factor in changes in ambient conditions and vary the flow volume accordingly. Most electronic mass flow controllers are calibrated for a target gas to provide accurate flow control over variations of temperature and pressure, but often this calibration drifts over time, requiring periodic recalibration while in-service. This increases maintenance, while a skipped calibration reduces the efficiency of the system.

Precision mass flow controllers without in-service calibration

The solution to this is a precision mass flow controller family that does not require in-service calibration. Sensirion has a solution with its SFC5500 series mass flow controllers (Figure 1). The SFC5500 series uses microthermal measurement of gas temperatures to accurately determine the precise SLM volume measurement, regardless of changes in gas temperature and pressure.

Figure 1: The Sensirion SFC5500 mass flow controller family uses microthermal CMOSens technology to accurately measure the volume of gas through the gas flow channel, regardless of temperature or pressure variations. (Image source: Sensirion)

Figure 1: The Sensirion SFC5500 mass flow controller family uses microthermal CMOSens technology to accurately measure the volume of gas through the gas flow channel, regardless of temperature or pressure variations. (Image source: Sensirion)

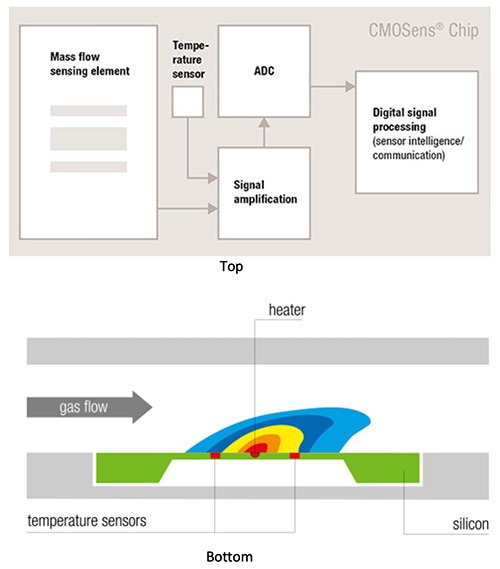

Called CMOSens, Sensirion’s gas volume flow technology accurately measures gas volume through the gas flow channel. CMOSens is a general term for Sensirion’s approach that combines the sensing, signal conditioning, and processing on a single CMOS device for precise control over time in a small device (Figure 2, top).

Figure 2: CMOSens combines the sensing, signal conditioning, and processing on a single CMOS device (Top). In a gas flow measurement application (Bottom), temperature sensors and associated processing perform microthermal measurement to ensure precision. (Image source: Sensirion)

Figure 2: CMOSens combines the sensing, signal conditioning, and processing on a single CMOS device (Top). In a gas flow measurement application (Bottom), temperature sensors and associated processing perform microthermal measurement to ensure precision. (Image source: Sensirion)

In the gas flow measurement implementation using CMOSens, temperature sensors are positioned upstream and downstream, with an adjustable heater mounted on a pressure-stabilized membrane in between (Figure 2, bottom). A third temperature sensor detects the temperature of the gas.

Gas flow over the two sensors and the heater create temperature readings at the two sensors. These two readings, along with the gas temperature sensor reading, are read by an integrated signal processor and combined with the stored calibration settings for the particular gas, producing an accurate reading of volume flow regardless of pressure and temperature.

The typical settling time for SFC5500 mass flow controllers is less than 100 milliseconds (ms), allowing for accurate readings during fast changes in temperature, pressure, and flow conditions. Because the CMOSens technology compensates for temperature and pressure, this configuration has zero drift over time, so an SFC5500 never needs recalibration in the field unless the target gas is changed.

Mass flow controller based on CMOSens

An example SFC5500 mass flow controller is the SFC5500-200SLM. It is a high-volume flow controller designed and calibrated for only air, nitrogen, and oxygen. Nitrogen and air gases are supported with a maximum full-scale volume flow rate of 200 SLM and a specified control accuracy of 0.10% of full-scale flow or 0.20 SLM. Oxygen gas flow is supported with a maximum full-scale flow rate of 160 SLM, with a specified control accuracy of 0.20% of full-scale flow or 0.32 SLM. Sensirion specifies that accuracy for this unit may deteriorate slightly when gas flow is above 100 SLM. The design of the SFC5500-200SLM is such that it allows precision control of air or oxygen without in-service calibration.

The Sensirion SFC5500-200SLM interfaces to a host computer by a common RS-485 DB-9 connector. DeviceNet and IO-Link communications are also supported. Gas ingress and egress connections are Legris compression fittings with a 10 millimeter (mm) outer diameter. This is compatible with standard 10 mm gas fittings.

To support other gases, Sensirion offers the SFC5500-10SLM multiple gas mass flow meter. Besides air, nitrogen, and oxygen, this controller also supports hydrogen, helium, argon, carbon dioxide, nitrous oxide, and methane. It supports a maximum full-scale flow of 10 SLM for all gases except nitrous oxide, argon, and carbon dioxide, with a full-scale flow of 5.0 SLM. Worst-case accuracy is 0.30% of full-scale flow. It supports the same communications interfaces as the SFC5500-200SLM. Gas ingress and egress connections are Legris compression fittings with a 6 mm outer diameter, compatible with standard 6 mm gas fittings.

The SFC5500-10SLM provides the flexibility to support multiple gases with one controller, simplifying inventory. The controller must be configured and pre-calibrated before being put into operation for the target gas being controlled. It cannot be used for another gas without being reconfigured.

Configuration and development

The SFC5500 mass flow controllers must be pre-configured for the target gas before being put into operation. Since different gases have different densities and properties, each gas requires a different setup and calibration. To help with configuration, calibration, and evaluation, Sensirion offers the EK-F5X evaluation kit for the SFC5500 series (Figure 3). Note that the kit does not include a mass flow controller.

Figure 3: The Sensirion EK-F5X evaluation kit allows developers to configure, calibrate, and evaluate SFC5500 mass flow controllers (not provided with kit) before putting them into service. (Image source: Sensirion)

Figure 3: The Sensirion EK-F5X evaluation kit allows developers to configure, calibrate, and evaluate SFC5500 mass flow controllers (not provided with kit) before putting them into service. (Image source: Sensirion)

To configure an SFC5500 for service, it must first be connected to the gas being controlled. The EK-F5X evaluation kit comes with a custom DB-9 cable which is plugged into the DB-9 connector on top of the SFC5500. The DB-9 cable splits off into an AC adapter for powering the SFC5500 while in operation, and a USB connector for interfacing to a host computer. A USB flash drive is included with the SFC5500 device driver for the host computer, along with the SFC5000 viewer software, both of which must be loaded on the host computer before connecting over USB. The SFC5500 is first plugged into power, then the USB connector is connected to the host computer. After the usual beeps as the computer acquaints itself with the USB-connected SFC5500, the SFC5xxx viewer software starts and asks for the COM port to be configured. The software then displays all available calibrations for each gas supported by the particular SFC5500, along with available calibrations (Figure 4).

Figure 4: The Sensirion SFC5500 viewer software provides a selection of calibrations for each gas supported by the connected unit. (Image source: Sensirion)

Figure 4: The Sensirion SFC5500 viewer software provides a selection of calibrations for each gas supported by the connected unit. (Image source: Sensirion)

The SFC5xxx viewer software displays the SFC5500 variation connected with its serial number and firmware version, along with the COM port configuration. The System tab is selected on startup and displays available flow calibrations highlighted in green, with the active calibration highlighted in red. To change a calibration, the calibration for the target gas is right-clicked, then “Load Calibration” is selected. The connected SFC5500 is now calibrated for the selected gas. Calibration is stored in EEPROM so it is not necessary to recalibrate after a power cycle. It is only necessary to recalibrate if the unit is used for a different gas.

After calibration, the Data Display tab is selected. This tab sets and controls the gas flow, which can be set to a constant flow rate, or a custom waveform can be generated to vary the flow. The SFC5500 is now calibrated and configured for automated operation.

For more complex applications where flow must be varied programmatically, the SFC5500 can be controlled by DeviceNet. The DeviceNet tab configures the DeviceNet MAC ID and baud rate. Flow is easily controlled remotely via DeviceNet by sending 0x0000 to the unit for no flow, 0xFFFF for full-scale flow, or any value in-between. This allows for complex flow control operations, and allows for a fast and easy remote shutdown of the gas flow, useful in emergency situations.

Conclusion

Accurate control of industrial gases is vital in industrial processes. While calibration drift can require periodic recalibration to maintain accuracy, new gas measurement technologies can eliminate the need, resulting in improved efficiency, reduced maintenance, and total cost savings over the long term.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.