How New IO-Link Masters Can Balance the Benefits of Cloud Connectivity and Local Control in Industry 4.0 Factories

Contributed By DigiKey's North American Editors

2024-11-06

Balancing the needs for Cloud connectivity and local control using programmable logic controllers (PLCs) in industrial networks just got easier. Industry 4.0 networks are complex and include multiple levels of connectivity from IO-Link on the factory floor to field busses like EtherNet/IP and PROFINET connecting machines and PLCs and an Open Platform Communications Unified Architecture (OPC UA) interface reaching up to the Cloud.

In a traditional Industry 4.0 network, sensors, actuators, and other devices use an IO-Link master to connect with the field bus network, and devices on the field bus network use OPC UA and other protocols to connect with the Cloud.

Machine and factory network designers now have a new tool — IO-Link masters — that combines the usual EtherNet/IP, PROFINET, and other field bus connectivity with an OPC UA interface for direct connection to the Cloud. That can be used to flatten connectivity and speed the delivery of critical data to the highest levels of the network.

This article starts with a review of the use of local control and Cloud connectivity in a traditional network architecture. It then presents the flattened architecture enabled by the new IO-Link masters from Pepperl+Fuchs, which includes field bus and OPC UA connectivity and can support multiple parallel connections. It also considers how the new Ethernet advanced physical layer (APL) technology fits in.

It closes by detailing the new IO-Link masters with OPC UA connectivity and compatible IO-Link hubs for network expansion, along with a few representative IO-Link devices and the use of an IO-Link USB master for configuring, commissioning, and trouble-shooting IO-Link devices.

Industry 4.0 factories require varying mixes of local control and Cloud connectivity. Each has its benefits. The best solution often combines PLCs and edge computers for responsive local control while using the Cloud to analyze complex data.

PLCs are rugged and designed for use in industrial environments. They are generally modular and can accommodate the changing needs of Industry 4.0 factories. PLCs are more compact and reliable than the relay-based systems they often replace. Perhaps most importantly, PLCs can support real-time control in critical applications with direct feedback from the connected machines and sensors.

Cloud connectivity provides essentially unlimited storage and computational capabilities. It can link data from various applications, controlled by individual PLCs, and support a harmonized and optimized overall factory operation. Cloud connectivity can offload administrative tasks from PLCs, and Cloud computing services can be quickly and economically scaled.

Traditional IO-Link

IO-Link is a point-to-point protocol, not a field bus. In a traditional Industry 4.0 network, IO-Link masters are the intermediaries between IO-Link devices on the factory floor and the field bus network. Each port on an IO-Link master connects to a single IO-Link device. The IO-Link master consolidates and translates communication from connected IO-Link devices and sends it on to the field bus network.

IO-Link masters are available for installation inside the control cabinet. They can connect to the field bus network as a remote connection point with an IP20 environmental rating or be used on the factory floor with an IP65/67 rating (Figure 1). There’s no direct connection between traditional IO-Link masters and the Cloud; all communications to the Cloud are channeled through and controlled by devices on the field bus.

Figure 1: Traditional network application of IO-Link connected to a field bus. (Image source: Pepperl+Fuchs)

Figure 1: Traditional network application of IO-Link connected to a field bus. (Image source: Pepperl+Fuchs)

Enhanced IO-Link and a parallel network

Adding OPC UA connectivity into an IO-Link master dramatically changes the possibilities for industrial network architectures. It’s no longer necessary for communications to be channeled onto the field bus to get up to the Cloud.

Time-sensitive data for real-time control can still be put onto the field bus. Less time-sensitive data can be aggregated and sent directly to the Cloud, removing that communication overhead burden from the field bus devices.

Pepperl+Fuchs refers to this new structure as a “parallel” architecture since it can be used in parallel with standard industrial machine control systems. The key is the company’s MultiLink™ technology that supports the parallel use of an industrial Ethernet field bus for connecting with PLCs using a protocol like EtherNet/IP and message queuing telemetry transport (MQTT). This open-source messaging protocol uses OPC UA and can connect with devices on the Industrial Internet of Things (IIoT), like industrial computers, supervisory control and data acquisition (SCADA) systems, and the Cloud.

To complete the package, IO-Link masters with MultiLink also include an integrated web server and IO-Link device description (IODD) interpreter that supports the configuration of the field bus connection and attached IO-Link devices using a web browser (Figure 2).

Figure 2: New IO-Link network architecture using OPC UA for direct Cloud connectivity and a flatter network structure. (Image source: Pepperl+Fuchs)

Figure 2: New IO-Link network architecture using OPC UA for direct Cloud connectivity and a flatter network structure. (Image source: Pepperl+Fuchs)

More networking choices

In addition to enabling the new parallel network architecture described above, IO-Link masters with OPC UA and MultiLink can be used for other use cases like:

Retrofits – This conventional IO-Link master can be replaced by one with OPC UA and MultiLink connectivity to add the benefits of parallel communication into an existing network.

Applications without a traditional PLC – Some applications, like an enterprise resource planning (ERP) or manufacturing execution system (MES), gather data from sensors on the factory floor and don’t need a PLC. An IO-Link master with OPC UA can send the data directly to the cloud, which can be aggregated, analyzed, and acted on to maximize productivity.

Applications with multiple PLCs – Complex welding cells are an example of an application with multiple PLCs and multiple protocols that can benefit from the addition of OPC UA. For example, a primary PLC can control the overall process using PROFINET communication, an industrial PC can control optical quality monitoring with EtherNet/IP communication, and various robots and other equipment may use proprietary control protocols. OPC UA with Pepperl+Fuchs’ MultiLink technology enables communication and data exchange between the systems despite the different field bus protocols, and it can link the entire welding cell to the Cloud.

Built on the foundation of Ethernet APL

MultiLink technology is built on the foundation of the Ethernet advanced physical layer, or Ethernet-APL, that allows Ethernet to be used for communication and power with process instrumentation over long distances. It's based on the 10BASE-T1L Ethernet physical layer standard.

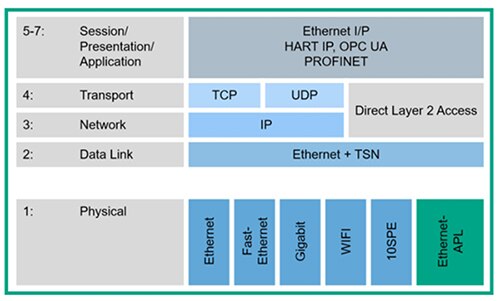

With a speed of 10 Mbps and a 1,000-meter range, Ethernet-APL was designed for real-time process monitoring and control, enabling parallel access. It supports EtherNet/IP, HART-IP, OPC UA, PROFINET, and other higher-level protocols. It eliminates the need for gateways or other protocol conversions. It implements 10BASE-T1L using a special Ethernet physical connection (PHY) in Layer 1 of the Open Systems Interconnection (OSI) model (Figure 3).

Figure 3: Ethernet-APL is a new PHY based on 10BASE-T1L. (Image source: Pepperl+Fuchs)

Figure 3: Ethernet-APL is a new PHY based on 10BASE-T1L. (Image source: Pepperl+Fuchs)

The new industrial networking tools

For industrial network designers who want to take advantage of the new possibilities enabled by IO-Link masters with OPC UA MultiLink parallel connectivity, Pepperl+Fuchs offers the ICE2 (with EtherNet/IP) and ICE3 (with PROFINET) IO-Link master series. Both types of IO-Link masters have eight inputs and outputs and come with a web-based configuration capability for setting all module parameters and all connected IO-Link devices (web IODD operation). They include integrated IODD storage for over 100 IODDs. Other features include:

- The PortVision® DX software supports network configuration, device management, and settings cloning/backup in one application.

- All module settings can be saved as a separate file and transferred to a new device using the cloning function to speed deployments.

- Block models have two L-coded M12 power connector plugs rated for 16 A. The inputs and outputs have A-coded M12 connector plugs, and connection to the field bus is made through D-coded M12 connector plugs.

- DIN rail models are available with screw terminals or pluggable push-in connectors.

- Degrees of protection: Block models are IP67 rated, and DIN rail models are rated for IP20 (Figure 4).

Figure 4: Examples of DIN rail (left) and block style (right) IO-Link masters. (Image source: Pepperl+Fuchs)

Figure 4: Examples of DIN rail (left) and block style (right) IO-Link masters. (Image source: Pepperl+Fuchs)

Exemplary IO-Link masters with OPC UA MultiLink include:

- The ICE2-8IOL1-G65L-V1D is a block-style EtherNet/IP and Modbus IO-Link master with four IO-Link Class A ports that can provide up to 200 mA of power for connected devices and four IO-Link Class B ports for higher-power devices with their own independent power source.

- The ICE2-8IOL-K45P-RJ45 is a DIN rail-style EtherNet/IP IO-Link master with eight inputs/outputs and push-in connectors.

- The ICE3-8IOL1-G65L-V1D is a block-style PROFINET and Modbus IO-Link master with 4 IO-Link Class A and 4 IO-Link Class B ports.

- The ICE3-8IOL-K45S-RJ45 is a DIN rail style PROFINET IO IO-Link master with eight inputs/outputs and screw terminals.

Hubs & converters for network expansion

IO-Link hubs support expanding networks of sensors, actuators, and other devices. IO-Link hubs allow several digital sensors and actuators to be connected to an IO-Link master using a standard sensor cable. For example, the ICA-16DI-G60A-IO IO-Link hub can handle up to 16 PNP digital inputs, and the logic level can be configured individually for each port. Depending on the capability of the connected IO-Link master, this hub can deliver up to 500 mA of power to connected devices. It’s rated for IP65, IP67 and IP69K.

When a sensor with an analog output needs to be connected to an IO-Link network, designers can turn to the ICA-AI-I/U-IO-V1 IO-Link converter with an analog input for current or voltage and an IO-Link output. It’s rated for IP67, and the input can be set as follows:

- Current input can be set as 0 to 20 mA or 4 to 20 mA.

- Voltage input can be set as -10 to 10 V or 0 to 10 V.

IO-Link device offering

A comprehensive ecosystem of IO-Link devices is available for almost every industrial process, including sensing and control needs. Pepperl+Fuchs’ IO-Link portfolio includes inductive proximity sensors, inductive positioning systems, photoelectric sensors, ultrasonic sensors, vibration sensors, rotary encoders, and identification systems (Figure 5). Examples include:

- The VDM28 distance measurement device uses Pulse Ranging Technology (PRT) to deliver a repeat accuracy of 5 mm with an operating range of 0.2 to 15 m and an absolute accuracy of 25 mm.

- The IUT-F191-IO-V1-FR2-02 RFID read/write device is optimized for industrial applications involving distances up to about one meter. The device reads and writes passive tags based on ISO/IEC 18000-63.

Figure 5: Examples of the wide range of available IO-Link devices. (Image source: Pepperl+Fuchs)

Figure 5: Examples of the wide range of available IO-Link devices. (Image source: Pepperl+Fuchs)

USB master for commissioning IO-Link devices

When it’s time to install and commission IO-Link devices, network technicians can turn to the IO-LINK-MASTER02-USB (Figure 6). This USB master can connect IO-Link devices to a USB port on a PC. It’s designed to support testing, configuration, and servicing activities. Connected devices can be configured and parameterized. Device diagnostics is also supported. Devices with a low current consumption can be powered directly from the USB master. Devices with higher power needs can be connected to an optional external power supply.

Figure 6: This IO-Link USB master connects to a PC to speed network deployments. (Image source: Pepperl+Fuchs)

Figure 6: This IO-Link USB master connects to a PC to speed network deployments. (Image source: Pepperl+Fuchs)

Conclusion

The addition of OPC UA parallel connectivity to IO-Link master devices has dramatically changed the options available to designers of Industry 4.0 networks. It’s now possible to flatten the network architecture and provide direct connections between the IO-Link devices on the factory floor and the Cloud. The new technology can be used in various use cases to improve operational efficiency.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.