How Delta Robotics Optimize and Streamline Electronics Manufacturing Processes

2023-04-19

Delta robots are relatively small robots employed in handling food items for packaging, pharmaceuticals for casing, and electronics for assembly. The robots’ precision and high speed make them ideally suited to these applications. Their parallel kinematics enables this fast and accurate motion while giving them a spiderlike appearance that’s quite different from that of articulated-arm robots.

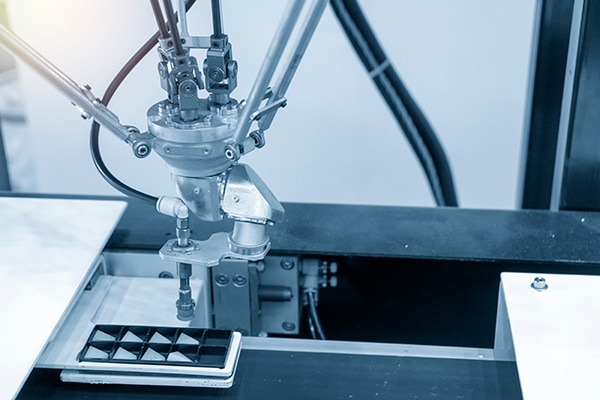

Figure 1: The robotic linkage-arm use in electronics production line with the lighting effect. - stock photo (Image source: Phuchit • Getty Images)

Figure 1: The robotic linkage-arm use in electronics production line with the lighting effect. - stock photo (Image source: Phuchit • Getty Images)

Delta robots are usually (though not always) ceiling mounted to tend moving assembly and packaging lines from above. They have a much smaller working volume than an articulated arm, and very limited ability to access confined spaces. That said, their stiffness and repeatability are assets in high-precision processing of delicate workpieces — including semiconductors being assembled.

Delta robots in context

Industrial robots are broadly categorized as mobile robots, serial manipulators, or parallel manipulators.

Mobile robots include autonomous ground vehicles (AGVs) and automated forklifts that are primarily programmed to move materials around factories and warehouses.

Robots classified as serial manipulators have a chain of kinematic linkages connecting a fixed base to an end effector; these robotics include articulated arms and cartesian robots. Because the rigidity and positional accuracy of each linkage is dependent on the previous linkage, serial manipulators are decreasingly accurate and rigid the further the linkage is from the base. Though there are exceptions, this morphology tends to limit the accuracy of six-axis robots to a few millimeters … and after rapidly moving to a new position and stopping, such robots’ end effectors will oscillate for some time before settling.

One type of serial manipulator use in many of the same applications as delta robots is the selective compliance articulated robot arm or SCARA robot. They’re mechanically quite simple with two revolute joints aligned so that their axes are parallel to each other and a third linear axis. The two revolute joints provide X-Y positioning in a single plane while the third linear axis provides motion in the Z direction. While they can lack the precision of delta robots, SCARAs are relatively low cost and can execute tasks quite rapidly — even in confined spaces.

Figure 2: A delta robot is a type of parallel manipulator with three parallelograms all connected to a single rigid body at the end effector end. The base of each parallelogram is actuated in a single degree of freedom relative to the robot’s base. Delta robots are typically ceiling mounted to tend conveyors or workpieces from above. (Image source: Wikimedia Commons)

Figure 2: A delta robot is a type of parallel manipulator with three parallelograms all connected to a single rigid body at the end effector end. The base of each parallelogram is actuated in a single degree of freedom relative to the robot’s base. Delta robots are typically ceiling mounted to tend conveyors or workpieces from above. (Image source: Wikimedia Commons)

In contrast with serial manipulators, robots classified as parallel manipulators (including delta robots) have multiple kinematic linkages connecting the end effector to the base. Such morphology makes for a much stronger, stiffer, and lighter structure than serial robot types. Their lightweight yet rigid structure lets delta robots quickly accelerate to deliver very short cycle times. Another type of parallel manipulator is the Stewart platform or hexapod; these deliver maximal stiffness, precision, and speed — often to correct for vibrations in real time in precision optics applications.

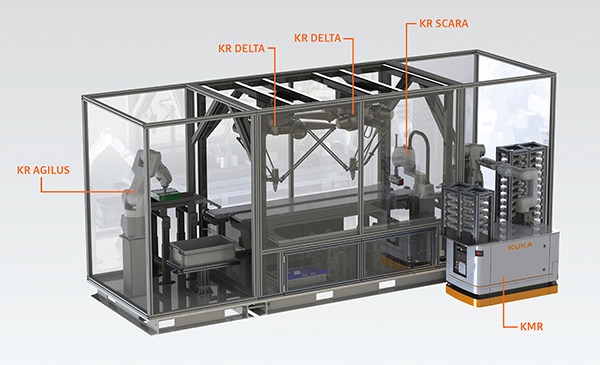

Figure 3: Shown here is a vision-laden work cell that employs delta robots, SCARA robots, and mobile robots. The delta robot is stainless steel and IP-67 rated. (Image source: KUKA)

Figure 3: Shown here is a vision-laden work cell that employs delta robots, SCARA robots, and mobile robots. The delta robot is stainless steel and IP-67 rated. (Image source: KUKA)

Typically each parallelogram on a delta robot is actuated by a rotary electric motor via linear actuation. (Low-cost delta robots from the Igus Drylin series use a less common linear-drive configuration.) The coupling of parallelograms constrains the end effector to only translational motion. That imparts the same degrees of motion as a three-axis cartesian machine but with a much stiffer and lighter structure. An added advantage of this configuration is that the mass of the drive motors is located in the (typically ceiling-mounted) base, so all the robot’s moving parts are passive lightweight structural elements. Some delta robots have additional rotary axes mounted in series at the end effector to provide four, five, or six-axis motion.

Overview of delta robot applications

Delta robots are widely used in pick-and-place applications for electronics assembly as well as food and pharmaceutical packaging. When a delta robot operates over one or more conveyors or mobile assembly platforms, items are conveyed or otherwise transported into the robot’s working volume. Then a vision system identifies parts’ exact locations and orientations to guide the robot on where and how to grasp or otherwise operate on the part.

Figure 4: This servomotor-driven delta robot moves to 200 cycles per minute in three degrees of freedom (DOFs) plus a rotational axis. A controller can command these robots’ axes with 2-msec response time to synchronize with conveyors and other tasks. In fact, another delta-robot is the Quattro; it has four instead of three parallelograms connecting the base to the end effector to deliver high stiffness and positioning accuracy at high speeds. (Image source: Omron Automation)

Figure 4: This servomotor-driven delta robot moves to 200 cycles per minute in three degrees of freedom (DOFs) plus a rotational axis. A controller can command these robots’ axes with 2-msec response time to synchronize with conveyors and other tasks. In fact, another delta-robot is the Quattro; it has four instead of three parallelograms connecting the base to the end effector to deliver high stiffness and positioning accuracy at high speeds. (Image source: Omron Automation)

So, the delta robot may pick up an item and then move it to its required location. Next, it might set the item down in the target place and orientation. For example, a delta robot may pick electronic components randomly orientated on a conveyor belt and assemble them onto a circuit board presented to the work cell via a second conveyor belt.

Multiple delta robots often work simultaneously along a line with two parallel continuously moving conveyor belts for on-the-fly pick-and-place. Centralized control systems coordinate the systems of such installations — with heavy reliance on machine vision to inform robot control routines. Each individual pick and place operation can take just a fraction of a second to complete.

With several delta robots operating at the same time, very rapid assembly and packaging is possible.

Delta uses specific to electronics manufacturing

Electronics manufacturing relies on delta robots for the transport and handling of printed circuit boards (PCBs) and components, PCB assembly, and device assembly.

PCBs are layered with nonconductive substrates and copper layers. Circuit layouts are typically printed on the board with lithography; then the rest of the copper layer is chemically etched away. Nonconductive solder masks are then applied to prevent solder bridging between closely positioned components and copper traces. PCB assembly involves placing and then soldering through-hole or surface mount technology (SMT) components. Older PCBs only used through-hole components, but this is now uncommon. Through-hole components have leads inserted through holes in the board and are soldered on the opposite side for greater mechanical strength, but this extra process makes them more difficult to assemble. No wonder SMT components now dominate for smaller components; they’re much better suited to highly automated volume manufacturing. That said, some through-hole mounting is often still required for larger components such as capacitors, transformers, and connectors.

Figure 5: Electronics boards ride a conveyor through an assembly work cell. (Image source: Getty Images)

Figure 5: Electronics boards ride a conveyor through an assembly work cell. (Image source: Getty Images)

For both kinds of PCB component attachment, machine vision complementing a delta robot can check the component variation and orientation before installation on the board. For high throughput, the robotic pick-and-place head may be designed to process several components at a time. A robotic end effector may also apply solder paste, and yet another may apply heat to electrically connect the installed components. Otherwise, components may be attached by a wave-soldering technique … though machines for this are expensive and best suited to very high-volume manufacturing. Even costlier is how components too large for insertion machines are often manually assembled onto semiconductor boards. Solder may also need to be manually applied in difficult-to-reach locations between components.

For the latter, delta robots can replace manual operations to place larger components and solder between components.

Delta robots can also be far less costly and far easier to configure than cartesian-type pick-and-place machines. After all, the latter are large and heavy — similar to CNC machine tools. Cartesian systems are difficult to move, and after being moved can require costly and time-consuming recalibration. In contrast, delta robots are small and light enough to relocate fairly frequently. After setup in the new location, they simply run a simple self-calibration routine and then resume operation.

Figure 6: Some delta robots maneuver through five axes to orient objects of all types. The IRB 365 shown here can sort, feed, pick, reorient, and place 1-kg products at 120 picks per minute — satisfying the requirements of production facilities needing high throughput and efficiency. Commanded by a compact delta-robot controller called the OmniCore, the system offers performance motion control, digital connectivity, and more than a thousand programmed functions. (Image source: ABB)

Figure 6: Some delta robots maneuver through five axes to orient objects of all types. The IRB 365 shown here can sort, feed, pick, reorient, and place 1-kg products at 120 picks per minute — satisfying the requirements of production facilities needing high throughput and efficiency. Commanded by a compact delta-robot controller called the OmniCore, the system offers performance motion control, digital connectivity, and more than a thousand programmed functions. (Image source: ABB)

Delta robot options abound. Codian Robotics specializes in only delta robots, in contrast with most industrial robot manufacturers that primarily produce articulated-arm robots. The supplier’s delta robots offer payloads of 1.5 to 125 kg to execute the assembly of tiny electronic parts to many designs far larger. A Mitsubishi Electric partnership pairs Codian delta robots with Mitsubishi controllers.

ABB’s delta robots are produced under the FlexPicker brand. The current model is the IRB 360, a delta robot with two auxiliary rotary axes in series at the end effector for five-axis motion. These robots are optimized for pick and place operations.

Fanuc produces delta robots in two ranges. The M-series includes small robots used for assembly of small parts (most commonly electronics) as well as larger robots. M-series robots are available in three, four, and five-axis configurations. The DR-3iB series robots are larger four-axis robots designed for picking and packing operations, with motion speeds of up to 5.5 m/sec and payloads up to 8 kg.

Conclusion

Delta robots provide affordable and flexible automation for electronics manufacturing. They often provide higher speed and more flexibility than other robotics and automated pick-and-place machines.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.