How Autonomous Vehicles Will Improve Sustainability and Productivity in Agriculture

Contributed By DigiKey's North American Editors

2023-02-08

Autonomous tractors, drones, and seed planting, weeding, and harvesting robots are several of the technologies under development that will transform agriculture and help alleviate food shortages by improving the sustainability and productivity of agricultural activities. Autonomous vehicles of all types will free people from driving tractors and other machinery, enabling them to perform more value-added activities. These include implementing precision agriculture that will boost yields, reduce negative environmental impacts, and improve the sustainability of agricultural operations by addressing issues related to water scarcity, labor shortages and other limitations.

While drones and agricultural robots represent new systems being developed and deployed from scratch, tractors are different. There’s already a large installed base of tractors, and they tend to have long operational lives. As a result, in addition to developing fully automated new designs, existing tractors will be retrofitted with electric drives and upgraded with digital systems for specific purposes, so-called “digital tractor implements.”

This article looks at the development of digital tractor implements and emerging electric tractors (e-tractors). It reviews the challenges in fielding autonomous tractors and looks at how drones, sensors on tractors, and AI and ML are used in precision agriculture. It also examines some of the technologies needed to realize the development of autonomous agricultural vehicles and how DigiKey’s extensive product offering, including machine vision, motors and controls, power converters, sensors and switches, wired and wireless communications interfaces, and a range of signal and power cables and connectors can help designers speed their development processes. The article closes by briefly looking into the future, where fully autonomous farms will be controlled by sophisticated operating systems that can manage mixed fleets, including both autonomous and standard farm equipment, to maximize productivity and sustainability.

Farm implements get on the ISObus

Like Industry 4.0, agriculture is moving toward using intelligent and interconnected machines. That’s where International Standards Organization (ISO) 11783, the tractors and machinery for agriculture and forestry serial data network bus, comes in. In the agriculture industry, it’s simply referred to as the ISObus. It’s based on the Society of Automotive (SAE) J1939 protocol, which includes the control area network (CAN) bus and has been optimized for agricultural applications. The ISObus is actively promoted by the Agricultural Industry Electronics Foundation, which works to coordinate enhanced certification tests for the ISO 11783 standard.

Before ISObus, farmers had tractors with proprietary control systems that limited flexibility, performance, and interoperability. The ISObus includes standardized connectors, communication protocols, and operational guidelines and enables the development of interconnected sensor and control systems from different makers (Figure 1). ISObus also supports the electrification of tractor implements, including electrically driven mechanical power take offs (PTOs) and high voltage connectors rated for up to 700 volts (V) and 100 kilowatts (kW) to power electrically driven implements.

Figure 1: ISObus can enable the integration of sensors and implements from diverse makers into a plug-and-play system. (Image source: Armin Weigel/dpa (Photo by Armin Weigel/picture alliance via Getty Images)

Figure 1: ISObus can enable the integration of sensors and implements from diverse makers into a plug-and-play system. (Image source: Armin Weigel/dpa (Photo by Armin Weigel/picture alliance via Getty Images)

The ISObus is evolving to develop a tractor implement management (TIM) system. As envisioned, the advanced version of the ISObus will enable implements to provide feedback to the tractor, supporting the optimization of the combined tractor/implement system. It will also allow higher levels of sensor integration on implements supporting precision farming. The tractor will provide location awareness, and the combined system will continuously gather data about the soil and crop conditions. With more detailed insights, yields and sustainability can both be increased.

e-tractors, retrofits, and autonomous tractors

In addition to the continuing development of the ISObus, the electrification of tractors will be important in the future deployment of autonomous vehicles and increased agricultural sustainability. Emissions reductions are an essential consideration. A quarter of the world’s greenhouse gas emissions come from agriculture and agriculture-related activities, and one tractor is equal in emissions to 14 cars.1

E-tractors are beginning to appear. In addition to reducing emissions, e-tractors can significantly reduce fuel costs. E-tractors are currently limited to smaller models as large, high-power e-tractors require battery packs larger than the size of the conventional tractor they would replace. Large e-tractors also weigh more, resulting in increased soil compaction that’s undesirable. Finally, charging times for large battery packs are too long to be practical in an agricultural operation. Smaller e-tractors with motors from 25 to 70 horsepower (HP), about 18.6 to 52 kW, and small battery packs are already being tested. Tractor electrification is about more than the drive train. It’s also about replacing hydraulics for powering and controlling tractor implements (Figure 2).

Figure 2: Small e-tractors with motors from 25 to 70 HP are being tested and readied for deployment. (Image source: Photo by brizmaker via Getty Images)

Figure 2: Small e-tractors with motors from 25 to 70 HP are being tested and readied for deployment. (Image source: Photo by brizmaker via Getty Images)

For larger tractors, hybrid retrofit kits are available. For example, one company offers a kit with a 250 kW generator that can be attached to the tractor’s existing internal combustion engine in place of the hydraulic pump. The kit also includes four electric motors to replace the hydraulic drive system and an electric transmission to power existing implements. By replacing the hydraulic systems, the retrofit kit reduces fuel and maintenance costs and increases the availability and reliability of the hybrid e-tractor.

Like the rollout of autonomous automobiles and trucks, the deployment of autonomous tractors faces an indeterminant future. For example, current regulations in California require that “all self-propelled equipment shall, when under its own power and in motion, have an operator stationed at the vehicular controls.” Full autonomy will have to wait.

Flying over the fields

Drones are currently used for a wide range of tasks in agriculture. Examples include:

- Imaging plant health. Drones have largely replaced satellite imagery to monitor crop health. Equipped with Normalized Difference Vegetation Index (NDVI) imaging equipment, drones provide detailed color images that can be used to monitor plant health. While satellite images take time to retrieve and can provide meter accuracies, drones can give the images millimeter accuracies and support highly targeted identification of diseases, pests, or other problems in real-time.

- Monitoring field conditions. Drones also monitor the soil and drainage conditions over entire fields. That can enable more efficient and sustainable watering programs.

- Planting. Automated drone seed planters are common in forestry industries, and their use is being expanded to general agriculture. Drones can rapidly plant trees or seeds and reach inaccessible areas more efficiently. For example, 400,000 trees can be planted per day by a team of two operators using multiple drones.

- Spray applications. The use of drones to apply spray treatments of fertilizers and pesticides is an emerging application whose use varies by region (Figure 3). For example, in South Korea, drones are used for about 30% of agricultural spraying. While in Canada, it’s not legal to use drones for agricultural spraying. In the U.S., drone spraying requires licensing and certification as mandated by the Federal Aviation Administration (FAA) and state agriculture, business, and transportation departments.

Figure 3: Large drones have been developed that can be used to apply spray treatments of fertilizers and pesticides. (Image: Photo by baranozdemir via Getty Images)

Figure 3: Large drones have been developed that can be used to apply spray treatments of fertilizers and pesticides. (Image: Photo by baranozdemir via Getty Images)

Precision produces more with less

Even before autonomous tractors are realized, drones and the electrification of tractors and tractor implements are expected to support precision agriculture and increase sustainability.

According to a study by the Association of [agricultural] Equipment Manufacturers (AEM), the use of precision agriculture can lead to a 4% increase in crop production, 7% increase in fertilizer placement efficiency, 9% reduction in herbicide and pesticide use, and 6% reduction in fossil fuel use2. In addition, water use can be reduced by 4% with precision irrigation.

Those numbers are based on current technology. With the addition of connected systems and artificial intelligence (AI), those improvements are expected to be multiplied. Adding machine learning (ML) for equipment maintenance provides further savings and improvements in sustainability.

According to the AEM, autonomous farm equipment is expected to result in an incremental 24% improvement when both input savings and yield improvements are considered. A significant factor in that improvement is the assumption that autonomous machinery will be lighter than the equipment it replaces, resulting in less compaction and improved soil conditions.

AI and ML will also be critical for developing precision machines optimized for specific tasks. Dedicated task machines can be even smaller than general-purpose tractors. For example, small task machines are being developed for picking crops where machine vision, a delicate touch, and precise dexterity are required.

Weed control is another area where task-specific AI and ML machines are expected to contribute significantly. Weed control is difficult, labor intensive, and, if not efficiently implemented, contributes to the use of more water and depletion of soil nutrients. Crop rotation is a partial solution but cannot eliminate the need for herbicides or manual weed control. Weed management robots that combine machine vision with AI and ML are being tested. These small machines also minimize soil compaction (Figure 4).

Figure 4: Example of harvesting autonomous robots that combine machine vision with AI and ML. (Image source: Photo by onurdongel via Getty Images)

Figure 4: Example of harvesting autonomous robots that combine machine vision with AI and ML. (Image source: Photo by onurdongel via Getty Images)

Farm OS and fleets of autonomous equipment

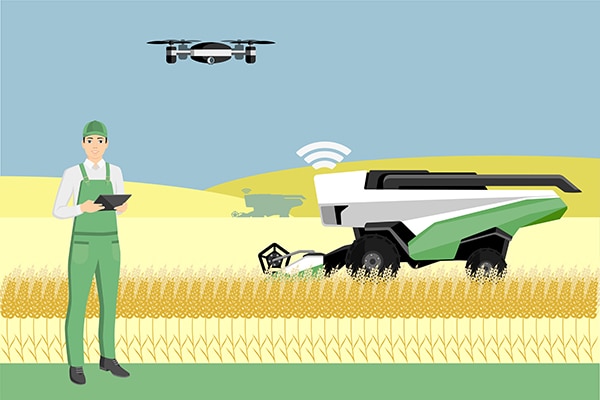

The agriculture industry is looking toward a future where fully autonomous farms will be controlled by a sophisticated operating system (OS) capable of managing mixed fleets, including both autonomous and standard farm equipment, plus land-based machines and drones, to maximize productivity and sustainability (Figure 5). Those fleets of farm equipment will be operated in coordination to help control capital expenses, minimize labor needs, and provide the big data necessary to enable autonomous execution and precision agriculture. In addition, the farm OS of the future will be standardized and optimized to support a diverse range of equipment from numerous suppliers. Adopting the ISObus is only the first step toward an open-source and standardized approach to farm automation.

Figure 5: Swarms of coordinated ground and flying autonomous agricultural machines will lead to higher levels of sustainability. (Image source: Illustration by Scharfsinn86 via Getty Images)

Figure 5: Swarms of coordinated ground and flying autonomous agricultural machines will lead to higher levels of sustainability. (Image source: Illustration by Scharfsinn86 via Getty Images)

Additional benefits expected from the proposed farm OS are reduced CO2 emissions, lower fuel consumption, and optimization of battery charging and management. Big data analytics will also play an important role in the future of agriculture. Large amounts of real-time data directly from the field will be used to continuously train the AI and ML algorithms required for decision-making, control, and operational planning to optimize precision agriculture.

Summary

It’s still in the early days for the development of autonomous farm vehicles and sustainable precision agriculture. The industry has started down the path with ISObus. The next generation of ISObus will support increased interoperability and help lead to more complex and interconnected fleets of farm equipment. The goal is the development of a farm OS that can take those fleets of farm equipment, combine them with massive real-time sensor data using AI and ML algorithms and deploy them as formations of coordinated ground and flying machines producing high levels of sustainability and productivity.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.