How Agile and Easy Commissioning of Industrial Motor Drives Can Elevate Sustainability and Productivity

Contributed By DigiKey's North American Editors

2024-07-10

Agile processes are a hallmark of Industry 4.0 factories and logistics operations. There’s a wide range of applications that require motors and variable speed drives (VSDs) rated 0.12 kilowatts (kW) to 30 kW (0.16 horsepower (hp) to 40 hp).

The VSDs for these applications must be easy to install and rated for operation from -10°C to +60°C. Larger drives should include integrated braking choppers, and some applications require compliance with electromagnetic compatibility (EMC) category C1 of EN 61800‑3. The VSDs need to be easy to use, operate over wide mains voltage ranges, and automatically adapt to unstable mains voltages to ensure uninterrupted operation.

Many applications automate simple motion sequences and don’t require programmable logic controllers, but they can be commissioned using preprogrammed macros or simple devices like parameter loaders, basic operator panels (BOPs), or smart access modules.

Finally, these VSDs need to be economical to operate and include integrated energy-saving functions like automatic flux reduction under predetermined operating conditions as well as the ability to monitor and display real-time energy consumption.

This article begins with an overview of the SINAMICS V20 family of VSDs from Siemens and the features that enable them to boost sustainability and productivity. It then delves into how preprogrammed macros and devices like parameter loaders, BOPs, or smart access modules can support agile commissioning, efficient operation, and ongoing maintenance.

SINAMICS V20 drives can be operated out of the box without any added modules or external controllers. The integrated BOP supports on-site commissioning. In addition, a universal serial interface can be used to connect with Siemens’ SIMATIC programmable logic controllers (PLCs) for complex operations. The Modbus interface can connect with third-party PLCs and other devices.

For units with a power rating over 10 hp, a braking resistor can be connected directly to the braking chopper, and some models comply with EMC category C1 of EN 61800‑3. SINAMICS V20 drives are specified for operation from -10°C to +60°C and are available with power ratings from 0.12 kW to 30 kW. Examples include (Figure 1):

- Model 6SL32105BB175UV1, rated for 0.75 kW, operates from 230 VAC single-phase power

- Model 6SL32105BB230UV1, rated for 3 kW, also operates from 230 VAC single-phase power

- Model 6SL32105BE322CV0, rated for 22 kW, operates from 400 VAC three-phase power

Figure 1: Examples of SINAMICS V20 drives, 0.75 kW (left) and 22 kW (right) (not to scale). (Image source: DigiKey)

Figure 1: Examples of SINAMICS V20 drives, 0.75 kW (left) and 22 kW (right) (not to scale). (Image source: DigiKey)

Integrated control modes in SINAMICS drives include scalar volts per Hertz (V/f), programmable V/f multi-point, V²/f that automatically adapts the flux to save energy, and flux current control (FCC) that automatically adapts the drive output to the load.

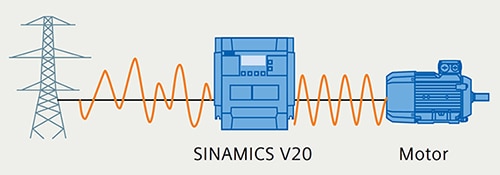

The Keep Running Mode automatically adapts to compensate for unstable mains power (Figure 2). In this mode, line voltage fluctuations are internally compensated, motor speed is automatically reduced to prevent an unscheduled shutdown, and an error message is sent if needed. This can be especially useful in building automation applications like pumps and fans in water or wastewater processing plants and heating ventilation and air conditioning (HVAC) systems.

Figure 2: SINAMICS V20 Keep Running Mode supports continuous motor operation even in the event of disturbances on the mains power. (Image source: Siemens)

Figure 2: SINAMICS V20 Keep Running Mode supports continuous motor operation even in the event of disturbances on the mains power. (Image source: Siemens)

Maximizing efficiency

Depending on the application, efficiency can be increased by adjusting the motor speed to suit the current process. For example, in the case of turbomachines like pumps, variable-speed operation can save up to 60% of the energy compared with fixed-speed operation.

SINAMICS V20 drives have an integrated energy-optimized control (ECO) mode for increased efficiency. In ECO mode, the motor flux is automatically adapted to the optimum operating point.

These drives can be set to hibernation mode, which powers down the motor while maintaining the drive’s current state. Hibernation mode substantially reduces energy consumption while maintaining the drive in a state of readiness to restart as needed immediately.

Using integrated cascading and energy balancing functions below can further enhance energy efficiency:

Cascading can be used in high-output pump, fan, and compressor applications that use multiple motors. Phase connection and disconnection using partially or fully controlled power cascades can increase overall system efficiency with no performance loss.

Energy balancing using coupled drives enables energy to be exchanged through the common DC link. That direct energy exchange between inverters can minimize overall system power losses and improve efficiency.

The BOP on SINAMICS drives can display real-time energy consumption. An energy savings counter can calculate the energy consumption during machine operation compared to fixed-speed operation, enabling operators to fine-tune processes and improve savings and sustainability further.

Elevating sustainability

Siemens has published the SINAMICS V20 Environmental Product Declaration (EPD), including a life cycle impact assessment (LCIA) based on International Standards Organization (ISO) 14021, Environmental labels and declarations - Self declared environmental claims - Type II environmental labelling.

This LCIA was based on the model 6SL3210-5BE21-5UV0, rated for 1.5 kW and 3-phase 380 VAC to 480 VAC mains power. It considers the impacts of manufacturing, distribution, operation, end-of-life decommissioning, and disposal and recycling of SINAMICS V20 drives. The most significant impact is from operation over the 15-year estimated lifetime of the drives. The analysis was based on 5,000 hours of operation per year and three operating points (OP):

- OP1: 20% of time at 100% speed and 100% torque

- OP2: 70% of time at 50% speed and 25% torque

- OP3: 10% of time at 20% speed and 25% torque

Drive operation was estimated to produce 1,059.13 kg CO₂ equivalent over 15 years, while manufacturing produced just 40.6 kg CO₂ equivalent, and decommissioning, disposal, and recycling was credited for recapturing some greenhouse gas emissions equaling -3.6 kg CO₂ equivalent.

In industry 4.0 operations, quick and flexible commissioning can be an important aspect of maximizing energy savings and sustainability. Users have several choices for speeding the commissioning of SINAMICS V20 drives to support rapid changeovers.

Agile commissioning with macros

The quick commissioning function changes four parameter sets simultaneously, including motor data, connection macros, application macros, and important parameters. Motor data begins with selecting European or North American parameters (i.e., kW vs hp), rated voltage, current, power, frequency, efficiency, etc.

The connection and application macros are especially important aspects of agile commissioning:

- Connection macros include identifying the BOP as the only control source or enabling control from PNP/NPN terminals, fixed speeds, analog input, fixed frequency, external push-button control, external push button with analog setpoint, PID control with analog input reference, PID control with the fixed value reference, USS control, and MODBUS RTU control.

- Application macro choices include a simple pump, fan, compressor, and conveyor. For example, parameters included in the simple pump macro are minimum frequency, control mode, inhibit frequency set point, automatic restart, and ramp-up time.

Individual parameters like frequency set point, minimum and maximum frequencies, and ramp-up and ramp-down times can be customized during quick commissioning. In addition to speeding commissioning, using the integrated quick commissioning function can eliminate errors from incorrect parameter settings, further shorting deployment times.

Cloning parameters to multiple drives

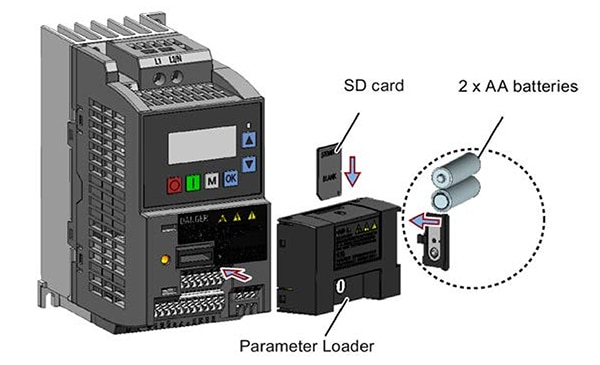

Once the parameter sets have been finalized, a parameter loader can upload and download parameter sets between the V20 and an SD card. The parameter loader and SD card can be used for cloning parameter sets across multiple drives. Parameters can be downloaded to drives even before the drives are delivered to the factory floor, further speeding up the overall commissioning process and reducing the need for technical support.

In addition to the SD card slot, the V20 parameter loader has a space for two AA-sized primary batteries that can power the drive during parameter downloading without being connected to a mains power source. The V20 parameter loader also has a Micro USB interface that can be connected to an external 5 VDC power supply, eliminating the need for the primary batteries (Figure 3).

Figure 3: An optional parameter loader can be used to upload or download V20 drive parameters to an SD card and enables rapid cloning of parameters to multiple drives. (Image source: Siemens)

Figure 3: An optional parameter loader can be used to upload or download V20 drive parameters to an SD card and enables rapid cloning of parameters to multiple drives. (Image source: Siemens)

External BOP

An optional external BOP can be used for remote control of V20 inverters. The external BOP is designed to be mounted on the outside of the equipment cabinet and linked to an interface module attached to the drive. The external BOP and interface module support RS232 connectivity and can be linked using a cable up to 3 m long.

With proper mounting, the external BOP can deliver IP54 and UL/cUL Type 1 enclosure ratings, providing protection to personnel against access to hazardous voltages and protection from solid foreign matter like dirt and dust for the V20 drive. The external BOP duplicates the integrated BOP interface on the V20 (Figure 4).

Figure 4: An external BOP can control V20 drives up to 3 meters away and outside the control cabinet. (Image source: Siemens)

Figure 4: An external BOP can control V20 drives up to 3 meters away and outside the control cabinet. (Image source: Siemens)

Wireless control

To achieve the ultimate flexibility in commissioning, users can turn to the SINAMICS V20 Smart Access module (Figure 5). The Smart Access module connects directly to the front of the V20 and is a Web server module with integrated Wi-Fi connectivity. It supports Web-based commissioning and monitoring of V20 drives from user devices like a laptop computer with a wireless network adapter, a tablet, or a smartphone. It can be used with any operating system and any HTML5-capable web browser like Chrome, Internet Explorer (IE), and Safari.

Figure 5: This Smart Access module provides Wi-Fi connectivity for commissioning, controlling, monitoring, and diagnosing V20 drives. (Image source: DigiKey)

Figure 5: This Smart Access module provides Wi-Fi connectivity for commissioning, controlling, monitoring, and diagnosing V20 drives. (Image source: DigiKey)

SINAMICS V20 Smart Access provides easy access to the drive, even in a difficult-to-access area. The intuitive graphical user interface (GUI) and commissioning wizard make it easy to use. Smart Access supports the same quick set-up wizard as the BOP for fast and easy commissioning, including:

- Entering motor data

- Connection macros can be activated

- Application macros can be selected and activated

- Commonly used parameters can be set

Smart Access can be configured to deliver fault codes via email for remote monitoring directly, and it includes numerous security features to control access to the data and control functions. Smart Access provides comprehensive wireless web-based functionality, including:

- Quick commissioning

- Converter parameterization

- Motor operation in JOG/HAND mode

- V20 status monitoring

- Fault and alarm diagnostics

- Data backup and restore

Conclusion

SINAMICS V20 drives from Siemens focus on sustainability and flexibility. With multiple operating modes and energy-saving functions, these drives can maximize efficiency in a wide range of simple motion applications from 0.12 kW to 30 kW. Keep Running mode ensures continuous operation of critical infrastructure like wastewater and water processing and HVAC in building automation systems. Flexibility is supported by the numerous ways to implement quick commissioning using the integrated BOP, a remotely located BOP, wireless connectivity with a Smart Access module, plus preprogrammed application macros and other tools.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.