High-Performance Cooling: How Diagonal Compact Fans are Changing the Game

Contributed By DigiKey's North American Editors

2024-02-08

In everything from cloud servers to mobile devices, powerful electronics are delivering immense benefits to businesses, consumers, and government. Still, they come with the challenge of how to cool vital components most effectively to provide speed, reliability, and data-crunching performance.

More powerful servers and edge devices are critical for fulfilling the promises of autonomous technologies, artificial intelligence, and Internet of Things (IoT) solutions related to 5G. Designing these systems to ensure performance and reliability requires multiple thermal management approaches, but the fans that exchange hot and cold air are crucial for most applications. That is why it is critically important for systems designers to plan on compact fans that have the ultimate cooling capabilities with minimal noise and footprint.

Overcoming compromises in electronics systems design

Since 1965, electronic systems design has grappled with the cooling demands from the phenomenal growing density of integrated circuits, famously predicted by soon-to-be Intel co-founder Gordon Moore.1 Since then, electronic systems designers have grappled with the cooling demands from the growing density of IC-based systems. When systems become overheated, components can shut down, or worse, be damaged.

The electricity that powers electronic systems is converted to heat, which must be displaced to prevent overheating. In the U.S., up to 40% of data center energy usage is for cooling; away from the data center, edge computing and a wide variety of IoT devices generally rely on advanced heat dissipation along with extreme miniaturization and reliability requirements. Cooling solutions for this broad spectrum of electronic systems often depend on energy-saving, low-noise compact fans that are simple to install and maintain.

Systems designers seeking to provide appropriate cooling are continually challenged by demands for ever-increasing power throughput, more rigorous energy-efficiency goals, and the need to accommodate smaller and smaller components. Simply planning to utilize a more powerful fan or plug in additional fans is unrealistic due to power consumption, space limitations, and noise constraints.

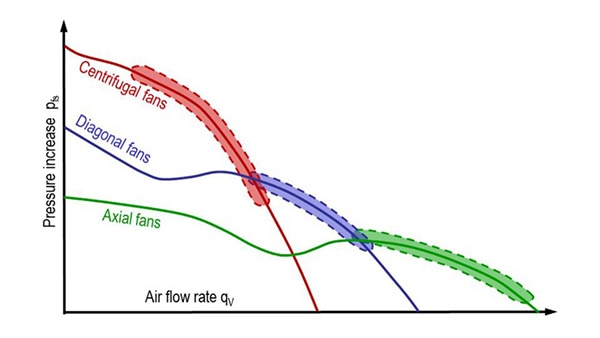

Designers have three basic options for fans and can utilize computational fluid dynamics (CFD) principles to determine which approach can provide the optimum balance between pressure and airflow to meet the needs of their applications (Figure 1):

- Axial fans move air parallel to the axis of the fan's rotating motor shaft, like a propeller.These are generally optimal for low-pressure, high-flow applications to replace hot air with cooling air. They are valued for their shallow installation depth, low noise generation, and efficiency, making them ideal for servers and storage devices where every centimeter of space is at a premium. Greater flow angles to the blades can generate more pressure, but that can result in increased turbulence and noise as well as reduced energy efficiency.

- Centrifugal — or radial — fans deflect air at a 90˚ angle to the shaft and can create more pressure with lower flow rates than axial fans. That makes them optimal for directing air through ductwork for ventilation, such as data center cooling, or for smaller applications like laptops, where circulation aims to move heat perpendicular to the air intake flow. The tradeoff is power requirements that exceed what is needed for axial fans.

- Diagonal fans pull in air like an axial fan but expel the airflow diagonally to the shaft. This allows compression levels similar to centrifugal fans, enabling higher static pressure with less turbulence and greater efficiency.

Figure 1: Optimal operating ranges of the three fan designs. (Graphic source: ebm-papst)

Figure 1: Optimal operating ranges of the three fan designs. (Graphic source: ebm-papst)

Next-generation axial fans

Axial compact fans dominate electronics cooling applications because they are easy to integrate and deliver optimum airflow rates. Integrated housings act as a suction funnel for air intake while providing a homogenous outlet flow without creating vortexes that would increase noise.

Traditional axial fans, however, are often pushed to their limits by the need for ever-increasing cooling capacity and more compact designs. Designers seeking to increase cooling capacity with traditional axial fans often rely on two-stage axial compact fans with counter-rotating rotors to provide the high pressure needed for uniform cooling throughout the enclosure. However, this increases energy consumption and operating noise.

Leading fan and motor innovator ebm-papst developed a diagonal compact fan, DiaForce, that overcomes these obstacles and is aimed at fulfilling the demanding future requirements of electronics cooling. Air flows through DiaForce fans in both axial and radial directions, enabling a compact axial fan unit that delivers the performance of a counter-rotating fan with less noise and significantly less power demand.

DiaForce fans integrate an external, state-of-the-art rotor motor directly with the axial impeller and can deliver the powerful airflow of an axial fan with the increased back pressure capabilities of a centrifugal fan (Figure 2). The unique geometry of the impeller and housing minimizes turbulence in the edge area to reduce noise, and it utilizes an impeller outlet opening that is larger than the intake opening to create airflow in both axial and radial directions.

Figure 2: A direct comparison between a single-stage axial compact fan (a), a two-stage axial compact fan (b), and the new DiaForce diagonal compact fan (c). (Photo source: ebm-papst)

Figure 2: A direct comparison between a single-stage axial compact fan (a), a two-stage axial compact fan (b), and the new DiaForce diagonal compact fan (c). (Photo source: ebm-papst)

ebm-papst developed the DiaForce diagonal compact fan for high availability requirements that typify applications such as data center servers, 5G standard communications, autonomous vehicles, and cloud services.

The geometry of DiaForce fans minimizes turbulence and enables a pressure increase greater than standard axial fans. According to ebm-papst, DiaForce is six dB(A) quieter than a conventional axial compact fan — with up to 50% more air performance2 — within the same dimensions as a conventional axial fan. It is compliant with DIN ISO 1940 specifications for dynamic balancing in two planes.

Unlike conventional single-stage fans, the speed at which DiaForce fans run can be increased to accommodate adverse conditions, such as an increase in the temperature of the external environment. High-efficiency, electronically commutated (EC) motors that drive DiaForce fans operate at an efficiency level of up to 90%, compared to the 20% to 70% efficiency level of AC motors. EC motors permit infinitely variable speeds and can provide the output levels of AC or DC motors in a smaller form factor.

The DiaForce120 Standard (part number 8315100198) delivers powerful cooling with minimal energy consumption and noise. It is available in a form factor of 119 mm width, 119 mm height, 86 mm depth, and a weight of 980 grams. Under specified standard test conditions, it delivers maximum free-airflow of 680 m³/h and maximum static pressure of 3.120 Pa. Depending on the operating point, it can achieve noise reduction from 6 dB(A) to 12 dB(A), according to ebm-papst.

Driving the DiaForce is a three-strand, energy-efficient DC motor rated at 500 W and a powerful microcontroller for intelligent motor regulation that enables maximum possible torque in all load ranges.

An optional integrated FanCheck diagnostic tool continuously calculates the realistic remaining service life based on the actual wear experienced, as well as the temperature, speed, and preset environmental parameters. With FanCheck, manufacturers and customers can eliminate the common practice of replacing fans sooner than their specified service life, reducing the associated costs, and making it easier to schedule replacement for the most opportune times.

Other available DiaForce fan options include:

- Go/No Go alarm

- Alarm with speed limit

- External temperature sensor

- Internal temperature sensor

- Analog control input

- Moisture protection

Conclusion

As governments, businesses, and consumers demand more energy-efficient computer and networking technology, electronic systems designers will be constantly challenged to deliver greater performance and energy efficiency. Modern fans created with condition monitoring capabilities and an eye on future needs are vital in meeting those challenges. The ebm-papst DiaForce diagonal compact fan can help designers overcome the obstacles to achieving higher cooling capacity in more compact designs.

Resources:

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.