Hands-on with Haptics-Enabled Product Design

Contributed By DigiKey's North American Editors

2024-03-06

The growing popularity and utility of devices that leverage digital tools and services are motivating more product designers to integrate haptic technology that ensures greater user engagement and delivers more immersive experiences. Enhancing digital interfaces with touch-based sensations adds tactile interaction, creating additional experiences that complement or go beyond sight and hearing. Designers eager to exploit haptic capabilities can take advantage of readily-available components to pursue new use cases and business opportunities.

Haptics are already being exploited in highly-visible consumer products ranging from smartphones to automobiles to point-of-sale devices and ATMs. They’re also being used in medical devices and surgical tools, industrial and manufacturing machinery, and building automation applications.

The origins of haptics date to 1880, when Pierre and Jacques Curie demonstrated the piezoelectric effect of some materials to generate a small electric charge by applying mechanical force. The reverse piezoelectric effect generates a physical motion of a material when a voltage is applied and was utilized to develop early ultrasonic submarine detection and airborne radio systems. Those same principles are at the heart of actuators and transducers commonly used in small speakers, microphones, and even musical gift cards.

Combining haptic capabilities with virtual reality (VR), augmented reality (AR), and the Internet of Things (IoT) holds the potential to vastly improve user engagement with existing devices and pave the way for new applications. Piezoelectric haptic actuators add a realistic touch to virtual interactions, with vibrations providing a natural and engaging sense of responsiveness, such as simulating gaming experiences from racing to weapons firing.

Haptics can play a critical role in overcoming factors that limit sight or sound in recognizing critical alerts. In medical settings, for example, haptics can help practitioners more readily react to multiple inputs, which could prove lifesaving in situations where every second can make a difference to a healthy outcome.

Feeling the future: applications and use cases

The potential of haptics is only limited by the vision of product designers. As AR and VR grow in popularity, and artificial intelligence (AI) and machine learning (ML) continue to evolve, haptics will likely play a prominent role in delivering ever-increasing immersive digital experiences across a range of industries, including:

- Medical fields, where haptics are already beginning to play a role in robot-assisted surgery and invasive dental procedures, helping to replicate the touch-and-feel experience doctors acquire over years of practice. Combined with VR, haptics can advance medical skills learning by simulating real-world procedures in a manner that provides hands-on experiences, from wielding a scalpel to palpitating a heart. Haptics can lead to advances in patient rehabilitation for victims of debilitating injuries, helping stroke victims relearn crucial motor skills and providing amputees with the ability to overcome the limitations of mechanical prosthetics.

- Automotive use cases, where haptics are already providing automobile drivers with tactile warnings for lane departure and failure to grip the steering wheel properly. Smartwatch integration with navigation systems can alert operators to upcoming turns, diminishing the need to shift their gaze to maps on their onboard screens.

- Industrial and manufacturing, where heavy equipment operators and production line workers can easily be distracted by the need to glance at buttons or screens. Haptics can help them stay focused on tasks ahead or behind them while confirming they made the right choices without looking away. Haptics can be incorporated into gloves and clothes to enable precise remote control of machinery, accuracy in picking operations, and to provide feedback or alerts in potentially hazardous environments.

- Retail and financial services, as customers are experiencing haptics in common everyday encounters with point-of-sale systems and ATMs, such as confirming interactions using cards and mobile devices. Combining haptics and AR/VR holds the potential for rich, online shopping experiences that allow consumers to replicate virtually what they expect in a physical retail operation.

- Consumer electronics, which has proven ripe for haptics. The first haptic smartphone was introduced at the 2000 Consumer Electronics Show and the technology was quickly adopted for Android and Apple smartphones, initially to help enhance the user experience when typing on virtual keyboards and pressing screen icons. But haptics found earlier success by enriching the experience of video gamers in the 1990s, with controllers and accessories such as steering yokes providing tactile feedback for driving and shooting games, among others. With the continuing evolution of consumer devices and digital services — from fitness trackers to AR/VR headsets and eyeglasses — product designers are racing to develop new capabilities that make the digital world as tangible as the physical.

Components for success: options for every need

Product designers can use readily available component portfolios to create haptic-enabled interfaces that fit their specifications and application needs.

The first step is understanding the differences between available technologies and their design requirements. Electromechanical components are the most common technology for delivering haptic responses. They are commonly grouped into the following main categories:

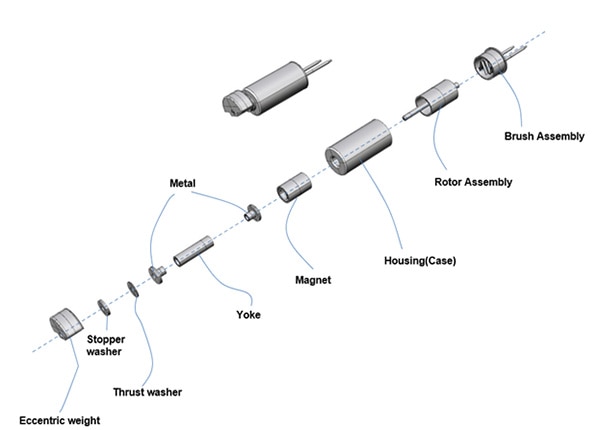

- Eccentric Rotating Mass (ERM) actuators utilize an off-axis rotating mass attached to a DC motor to generate vibrations that can deliver low-frequency "rumble" sensations (Figure 1). The actuator vibrates at a frequency directly correlated with the driving voltage of the device. Because it takes a short time for the rotating motor to achieve the desired speed when voltage is applied — and to slow the motor to a stop — they are best for applications where a noticeable vibration effect is required, but precise vibration patterns are not strictly needed. PUI Audio offers several ERM actuators, including the surface mount HD-EMB1104-SM-2, which delivers strong haptic feedback in a small package measuring 3.4 mm by 4.4 mm by 11 mm. It is suitable for medical, automotive, or industrial segments; consumer or portable devices; or security appliances. Another option is the PCI Audio HD-EM0602-LW15-R brushless DC ERM, which has improved speed and torque control and a longer lifespan than brushed actuators.

Figure 1: Exploded view of an ERM actuator. (Source: PUI Audio)

Figure 1: Exploded view of an ERM actuator. (Source: PUI Audio)

- Linear Resonant Actuator (LRA) parts (Figure 2) are AC-driven and produce a vibration in two directions along one axis, enabling high-resolution, responsive vibration patterns to deliver information to the user. LRAs create vibrations by moving the mass in a linear direction when the coil is excited with the frequency and voltage of the signal applied to the device, providing independent control over both vibration strength and frequency. Unlike ERMs, with an LRA-equipped device, users will feel a vibration as soon as the coil is excited and the mass moves up or down. This technology is related to traditional speakers in which a coil is excited by a waveform, causing a magnet and diaphragm to move and generate sound waves. The HD-LA1307-SM from PUI Audio is a waterproof, IP-rated, surface mount LRA that facilitates seamless integration into various end applications, such as virtual reality environments, gaming consoles, medical simulators, handheld devices, and consumer and industrial control interfaces.

Figure 2: Exploded view of an LRA. (Source: PUI Audio)

Figure 2: Exploded view of an LRA. (Source: PUI Audio)

- Voice Coil Motors (VCM), also called Voice Coil Actuators (VCA) (Figure 3), use the same voice coil technology as LRAs but are even more analogous to a speaker. A mass moves linearly, like in an LRA, but with increased size and mass, producing a more substantial and realistic vibration effect than what could be replicated with an LRA. PUI Audio’s HD-VA2527 cylindrical VCM offers flexible and complex vibration effects.

Figure 3: VCA exploded view. (Source: PUI Audio)

Figure 3: VCA exploded view. (Source: PUI Audio)

- Piezoelectric haptic components, often referred to as piezo benders or buzzers, are based on the reverse piezoelectric effect and comprised of flat layers of active piezoelectric material that bend and contract when voltage is applied, creating sound and vibration. They are available as disks like PUI Audio's HD-PAB1501, and strips like the HD-PAS2507. Piezo benders can deliver more complex and detailed signals, such as the sound of a heartbeat, an unprecedented sense of realism. These components offer higher displacement precision, faster response speed, more significant generating force, and longer life. They do require a higher voltage than ERMs and LRAs, but designers can utilize "bender driver" integrated circuits to meet the voltage requirements from low-voltage sources.

Conclusion

Product designers can take advantage of rich component portfolios to integrate haptics into their devices. They must evaluate what type of vibration is appropriate for their design, as well as the benefits and limitations of each actuator in meeting design specifications, end-user needs, and specific applications. With the right design choices, it is possible to create new haptic-enabled products that will spur new business opportunities.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.