Ensure Safe and Reliable EV Charging Using Multilayer Ceramic Capacitors With Flexible Terminations

Contributed By DigiKey's North American Editors

2023-06-08

While the amount of electronics in vehicles is increasing rapidly, the industry focus has tended to be on sensors, engine control units (ECUs), navigation, in-cabin connectivity, audio, and advanced driver assistance systems (ADAS). As electric vehicles (EVs) go mainstream, high-voltage, high-reliability electronic components that can tolerate upwards of 800 volts while also meeting stringent environmental requirements have become critical. This need applies right down to the capacitor level.

Along with compliance with standards such as AEC-Q200 for stress resistance, automotive designers selecting capacitors must consider many physical and electrical characteristics depending upon the specific application. Capacitors with tight tolerance and stable temperature coefficients are required for feedback loops. In high-frequency applications, the equivalent series inductance (ESL) must be low. In power applications, components with low equivalent series resistance (ESR) are needed if high ripple currents are anticipated. For EVs, minimizing size and weight are also important.

To address these requirements, safety-certified surface mount multilayer ceramic capacitors (MLCCs) are now available that comply with multiple international safety specifications and certifications—including AEC-Q200.

This article describes the structure of MLCC capacitors and what’s required of MLCCs for EVs. It then shows how the inherent size and volumetric efficiency, as well as features such as FlexiCap termination and high withstand voltages, help MLCCs meet the physical and electrical requirements. Real-world examples from Knowles Syfer are provided.

The structure of MLCCs

MLCCs are surface-mount capacitors that comprise several individual capacitor elements stacked vertically and connected in parallel by the end terminations. Hence the term multilayer (Figure 1).

Figure 1: A cross-sectional view of the structure of an MLCC shows multiple capacitor layers stacked in a common package. (Image source: Knowles Syfer)

Figure 1: A cross-sectional view of the structure of an MLCC shows multiple capacitor layers stacked in a common package. (Image source: Knowles Syfer)

To construct an MLCC, layers of the ceramic dielectric are built up using a screening process alternating with electrodes of alternate polarity. This permits a very large number of layers to be created. The parallel connection of these multiple electrode positive (+) and negative (-) pairs permits the manufacture of large capacitance values in a relatively small package.

The electrodes are metallic and highly conductive. The manufacturing process requires the electrodes to be chemically unreactive and have a high melting point. For this, the Knowles Syfer MLCC capacitors use a combination of silver and palladium as electrodes.

Dielectrics must also be good insulators. The relative permittivity—or dielectric constant (er)— determines the attainable capacitance for a given component geometry. For example, Knowles Syfer enhanced safety certified surface-mount MLCCs come with two classes of ceramic dielectrics. The first is C0G/NP0, an EIA Class 1 dielectric, which has a permittivity of between 20 and 100, relative to the permittivity of a vacuum which has an er of 0. The second is X7R, an EIA Class 2 dielectric, with an er of between 2000 and 3000. As a comparison, the er of mica is 5.4, and plastic film is 3. So, the ceramic capacitor will be smaller for a given capacitance value. The selection of the dielectric affects the stability of the capacitor with respect to temperature, applied voltage, and time. In general, the higher the er, the less stable the capacitance value.

The EIA classifies Class 2 dielectrics with an alphanumeric classification. The first letter designates the minimum temperature, the number indicates the maximum temperature, and the final letter describes the capacitance tolerance. The X7R dielectric decodes into having a minimum temperature of -55°C, a maximum temperature of +125°C, and a capacitance tolerance of ±15%. Class 1 dielectrics like C0G have a similar coding. The first character, a letter, gives the significant figure of the capacitance change with temperature in parts per million per degree Celsius (ppm/°C). For the C0G dielectric, the C represents a zero ppm/°C significant figure for temperature stability. The second number is the multiplier for the temperature stability. The 0 indicates a multiplier of 10-1. The final letter, G, defines the capacitance error of ±30 ppm.

Class 1 dielectrics offer higher accuracy and stability. They also exhibit lower losses. Class 2 dielectrics are less stable but offer higher volumetric efficiency, thereby providing greater capacitance per unit volume. Consequently, higher value MLCC capacitors generally use Class 2 dielectrics. The Knowles Syfer enhanced safety certified MLCCs have a high capacitance range of 4.7 picofarads (pF) to 56 nanofarads (nF), depending upon the choice of dielectric, and voltage ratings up to 305 volts alternating current (VAC).

The capacitance of an MLCC is directly proportional to the overlapping area of the electrodes, as well as the er of the ceramic dielectric. Capacitance is inversely proportional to the thickness of the dielectric, while the voltage rating is proportional to it. As such, there are tradeoffs between the capacitance, the voltage rating, and the physical size of the capacitor.

MLCCs for EVs

MLCCs have relatively low ESL and ESR, making them better suited for high-frequency applications, and with a wide choice of dielectrics, the capacitance values and tolerance range can be optimized to the application. They are surface-mount components with very volumetrically efficient packages, which helps them address space constraints in EVs. They are also highly resistant to voltage transients compared to aluminum electrolytic and tantalum capacitors.

While MLCCs are widely used, if subjected to mechanical stress due to vibration or shock, they can crack. Cracks open the device up to degradation through moisture contamination. Knowles Syfer designers have addressed this issue by creating FlexiCap terminations that offer increased tolerance to component flexure (Figure 2).

Figure 2: The FlexiCap design uses a proprietary flexible epoxy polymer termination base under the usual end-cap barrier to provide greater resistance to damage due to board flexure. (Image source: Knowles Syfer)

Figure 2: The FlexiCap design uses a proprietary flexible epoxy polymer termination base under the usual end-cap barrier to provide greater resistance to damage due to board flexure. (Image source: Knowles Syfer)

The flexible termination base used in FlexiCap is applied over the electrodes. This material is a silver-loaded epoxy polymer that is applied using conventional termination techniques and is then heat cured. It is flexible, absorbing some of the mechanical strain between the board and the mounted MLCC.

As a result, components terminated with FlexiCap withstand greater levels of mechanical strain when compared with sintered terminated components. FlexiCap also offers enhanced protection against mechanical cracking and in applications where rapid temperature changes occur. For designers of EVs, the result is a greater degree of flexure tolerance in the handling of in-process boards, translating to increased yields and fewer field failures.

Also important for EVs, the Knowles Syfer safety certified capacitors are available with AEC-Q200 qualification. Parts are deemed to be “AEC-Q200 qualified” if they have passed the stringent suite of stress tests for temperature, thermal shock, moisture resistance, dimensional tolerance, resistance to solvents, mechanical shock, vibration, electrostatic discharge, solderability, and board flex, among others.

Electrically, the safety certified line features a high dielectric withstand voltage (DWV) of 4 kilovolts direct current (kVDC) and 3 kVRMS. These are critical characteristics for EV 800 volt charging systems where wide test and safety margins are needed.

Examples of MLCCs for EVs

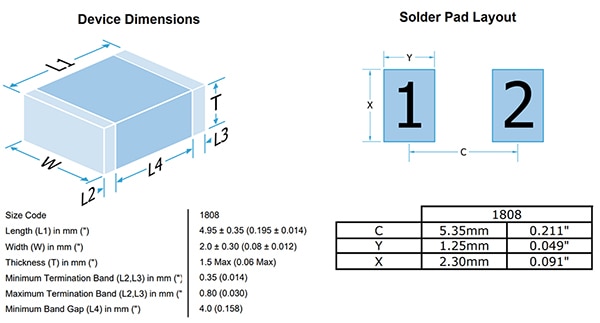

From the Knowles Syfer enhanced safety certified line, a wide range of capacitor values feature both Flexicap termination and AEC-Q200 qualification, making them particularly suited to EV applications. For example, the 1808JA250101JKTSYX is a 100 pF C0G/NP0 capacitor with a voltage rating of 250 volts AC for Class Y2 (line to ground) applications, and 305 volts AC in Class X1 (line to line) applications, with a tolerance of ±5%. It is housed in an 1808 package with dimensions of 0.195 x 0.079 inches, or 4.95 x 2.00 millimeters (mm) (Figure 3).

Figure 3: Shown are the physical dimensions of the 1808JA250101JKTSYX MLCC (left) along with its recommended solder pad layout (right). (Image source: Knowles Syfer)

Figure 3: Shown are the physical dimensions of the 1808JA250101JKTSYX MLCC (left) along with its recommended solder pad layout (right). (Image source: Knowles Syfer)

A typical X7R capacitor is the Knowles Syfer 1812Y2K00103KST, a 10000 pF ±10% 2 kV device in an 1812 package with dimensions of 4.5 x 3.2 x 2.5 mm. Both the 1808JA250101JKTSYX and 1812Y2K00103KST capacitor types have a rated temperature range of -55°C to +125°C. The product line is available in case sizes 1808, 1812, 2211, 2215, and 2220, depending on the dielectric used, capacitance value, and voltage rating.

Other examples include the Knowles Syfer 1808JA250101JKTS2X, a 100 pF, 250 volt AC (Class X2), 1 kV DC, C0G/NP0 capacitor with a ±5% tolerance. The 2220YA250102KXTB16 is a 1000 pF ±10% 250-volt X7R capacitor.

Note that the manufacturing requirements for mounting and soldering FlexiCap terminated capacitors are identical to those for an MLCC with a standard sintered termination, so they don’t require special handling. In addition, and referencing Figure 3 again, Knowles chip capacitors can be mounted using pad layouts that conform to IPC-7351, Generic Requirements for Surface Mount Design and Land Pattern Standards. Beyond that, other factors have been shown to reduce mechanical stress, like reducing the pad width to less than the chip width.

Conclusion

The Knowles Syfer Flexicap AEC-Q200-qualified MLCCs are well-suited for EV applications, especially 800-volt battery systems where an increased test voltage and safety margin to handle surge and transient conditions is essential. The FlexiCap termination makes the capacitors able to handle greater levels of mechanical stress. As such, and meeting AEC-Q200, they offer designers a unique combination of capability, stability, and safety certification.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.