Elevating Functional Safety with Relay Modules

Contributed By DigiKey's European Editors

2023-11-09

Functional safety is crucial to today's industrial systems, guaranteeing the secure operation of machinery and processes even when confronted with errors or malfunctions. Relay modules assume a key role in ensuring functional safety by offering a reliable mechanism for regulating electrical circuits. This article, focused on the Weidmüller SAFESERIES product family, examines the importance of relay modules in the context of functional safety, highlighting their essential characteristics and providing guidelines for optimal selection and utilization.

Meeting functional safety needs

Electromechanical relays are commonly used to control high-power electrical circuits with low-power signals. They function as switches, permitting or preventing the passage of current depending on the status of an input signal. Relay modules are utilized in functional safety applications to ensure that critical safety functions are reliably carried out and potential hazards are minimized. A few of the most important aspects of relay modules in functional safety are as follows:

- Redundancy: Redundancy is one of the fundamental principles of functional safety, requiring multiple independent components to perform the same safety-critical function. Relay modules are frequently redundantly configured to ensure a system can continue to safely operate even if one relay fails.

- Failure-safe design: Relay modules are typically designed to malfunction in a safe state; if a relay fails or loses power, it will default to a state that ensures the system's safety. For example, a failed relay in a circuit regulating the emergency stop of a machine should result in an immediate stoppage.

- Diagnostics and monitoring: Integrated into advanced relay modules, these capabilities allow the system to detect defects or malfunctions in the relay and initiate the appropriate responses, such as fault alarms or switching to a redundant relay.

- Reliability and robustness: Relay modules are well-known for their durability and dependability. They can withstand extreme environmental conditions, temperature fluctuations, and mechanical stress, making them suitable for use in demanding industrial settings.

- Low latency: In safety-critical applications, response time is of the utmost importance. In applications where quick response times are required to ensure the safety of personnel and equipment, relay modules are preferred.

When implementing relay modules in functional safety applications, several considerations must be made, starting with standards compliance. This ensures that the relay modules used in functional safety applications comply with relevant safety standards and certifications.

The European Committee for Electrotechnical Standardization (CENELEC) developed the EN 61810 series, which concentrates on electromechanical elementary relays. The series comprises several standards, each tailored to specific relay varieties and applications. EN 61810-3 is one of these standards, and its Type A variant is of particular significance.

Safety relays

The EN 61810-3 Type A standard applies to elementary relays that incorporate specific design and construction techniques to guarantee that the normally open (NO) contacts cannot assume the same position as the normally closed (NC) contacts. These relays, specifically built with forcibly guided contacts to comply with the standard, possess the capability to be employed in self-monitoring, safety-related control systems.

Forcibly guided contacts are mechanically linked to ensure that the NC opening contacts and NO closing contacts never close simultaneously in the presence of, for instance, a micro-welding of the contacts caused by arcing (“relay sticking”).

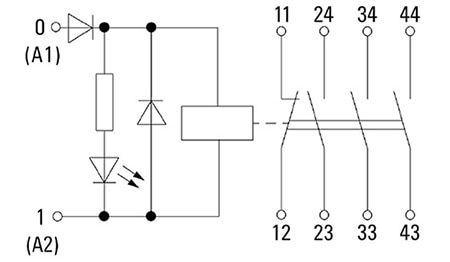

A practical example of this safety mechanism is shown in Figure 1, referring to a Weidmüller safety relay module featuring 3 NO contacts and 1 NC contact. As seen in the image, all the poles are mechanically connected through a bar, preventing independent movement.

If the NC contact is welded, none of the NO contacts can close during the relay’s energization. Similarly, if any of the NO contacts are welded, during the relay’s de-energization, the NC contact cannot close. In combination with a special circuit, malfunctions in the opening are detected. This is the most reliable way to ensure the maximum safety of man and machine.

Figure 1: Diagram of a Weidmüller safety relay module. (Source: Weidmüller)

Figure 1: Diagram of a Weidmüller safety relay module. (Source: Weidmüller)

Safety relays enable reliable implementation of safety functions on machines and systems to monitor emergency stop button signals, light curtains, safety door switches, and more. A quick response is needed in the event of an emergency in a plant. The "energized to safe" (ETS) protocol should be used to turn on sirens, warning lights, or cooling systems, whereas the "de-energized to safe" (DTS) procedure should be followed to turn off motors or emergency stop valves. IEC62061 and SIL 3 compliant activation and deactivation of safety-related applications are guaranteed using relays with redundant contacts.

After repeated use, the metal contacts in a switching relay that is not compliant with safety standards may weld. Even if the operator clicks the emergency stop button, the machine will continue operating in an unsafe mode. There is a risk to both the operator and the machine. Relays that are not certified as safe cannot be used on potentially dangerous machinery or installations, as mandated by national and international safety requirements.

Due to their increased safety and dependability, relays with positively driven contacts are gaining popularity. Relay modules with positively driven contacts employ redundant circuits and mechanisms as their principal technology. These redundant features are designed to ensure that the relay remains in a secure condition even if the control circuit or the relay itself fails. This redundancy is essential for applications where safety and dependability are important.

The reliability and safety features of these relay modules make them suitable for a variety of applications, such as:

- Industrial automation

- Medical devices

- Power generation and distribution

- Telecommunications

- Transportation

In these types of relays, with the main and auxiliary contacts mechanically connected, the position of the auxiliaries can be used to determine the position of the main contacts in the power circuit. Therefore, it is possible to determine whether the contactor has remained closed (due to contact sticking) even though its coil has been de-energized. If a power pole contact is welded, the mechanical connection prevents the open auxiliary contact from closing when the coil is de-energized.

Weidmüller’s SAFESERIES relay modules

In the field of electrical engineering, safety and dependability are of the utmost importance. This dedication to precision and dependability has resulted in the creation of advanced components such as Weidmüller's pluggable relay modules that feature positively driven contacts. These innovative relay modules represent a significant stride forward in technology, offering enhanced safety, efficiency, and flexibility in a wide range of applications.

At the heart of these relay modules is a technology that guarantees the contacts are positively driven, meaning that they transition between open and closed states in a controlled and dependable manner. This mechanism precludes the possibility of unintended contact operation, regardless of relay or control circuit faults. Consequently, the resulting relay prioritizes safety without sacrificing performance.

Weidmüller's SAFESERIES contact extension is compliant with EN 61810-3 Type A, consisting of relays that have forcibly guided contacts. Because of this, they are particularly well-suited for signal monitoring in applications that are concerned with the safety of both people and machinery.

The SAFESERIES is comprised of four separate pluggable relays with matching screw sockets in the following contact versions:

- 2 NO + 2 NC

- 3 NO + 1 NC

- 4 NO + 2 NC

- 3 NO + 3 NC

Achieving the highest performance level of PL ‘e’ for an application is possible if it has been designed in accordance with the standard EN/ISO 13849-1. The fundamental component can also be used for safety applications in accordance with IEC/EN 62061, which allows for the achievement of SIL 3 levels of safety integrity.

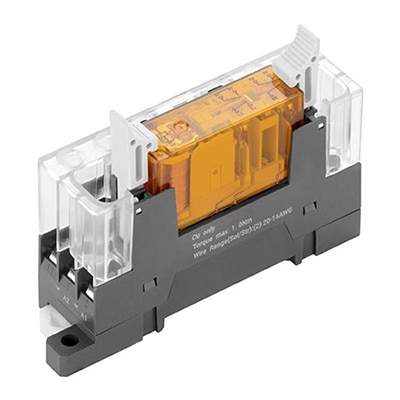

Figure 2 shows the Weidmüller 2759070000 safety relay module enclosed in an assembly suitable for DIN rail applications. It is a 4-position, general purpose relay with 3 NO contacts and 1 NC contact with a 24 VDC ±10% coil. The device can be energized by applying a coil-rated DC current of 20 mA with a rated switching voltage of 250 VAC and AgSnO gold-plated contacts that are rated for a continuous current of 6 A. On the load side, the maximum switching voltage is 400 VAC and 250 VDC. As shown in the diagram of Figure 1, the relay integrates a status indicator (green LED) and a free-wheeling diode for protection. The switch-on and switch-off delay is less than 20 ms, and the device’s lifetime is 10 x 106 switching cycles.

Figure 2: Weidmüller’s 2759070000 SAFESERIES relay module. (Source: DigiKey)

Figure 2: Weidmüller’s 2759070000 SAFESERIES relay module. (Source: DigiKey)

Another product of the SAFESERIES, the 2759030000 miniature industrial relay, is shown in Figure 3. Featuring 3 NO contacts and 1 NC contact, this relay with forcibly guided contacts is suitable for general purpose applications and has through-hole mounting.

Figure 3: Weidmüller’s 2759030000 SAFESERIES relay module. (Source: DigiKey)

Figure 3: Weidmüller’s 2759030000 SAFESERIES relay module. (Source: DigiKey)

Conclusion

Relay modules are essential components in functional safety systems because they ensure dependable control and carry out essential duties. Because of their robustness, fail-safe design, and compatibility with redundancy, they are frequently selected for use in applications where the highest level of safety is required. Relay modules make a substantial contribution to the overall safety and dependability of industrial and automotive systems when they are utilized appropriately and in conformity with applicable standards. Relay modules continue to develop and grow alongside technological advancements, adding increasingly complex features to satisfy the ever-increasing requirements of functional safety.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.