Don’t Forget About Thermal Interface Materials

2023-05-02

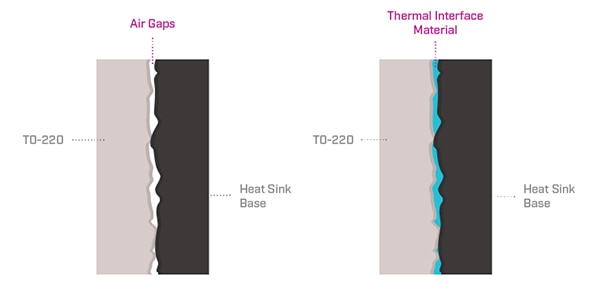

In the realm of thermal management, much attention is paid to fans, heatsinks, and Peltier devices, potentially making it easy to forget the manner in which these components are assembled. A Thermal Interface Material (TIM) is of utmost importance in providing optimal performance of these other thermal management techniques. The purpose of TIMs is to occupy the tiny, microscopic voids that are present between two non-uniform surfaces with a substance that boasts better thermal conductivity than air. TIMs can comprise various materials utilized to enhance thermal conductivity, ensuring efficient heat transfer from a heat-generating element like a power transistor to a heat dissipator like a heatsink, thermoelectric cooler, or both. This article will work to define thermal conductivity and impedance in greater detail while providing a high-level primer on the different types of TIMs available to a design engineer.

Figure 1: A basic representation of a TIM filling air gaps between two non-uniform surfaces. (Image source: Same Sky)

Figure 1: A basic representation of a TIM filling air gaps between two non-uniform surfaces. (Image source: Same Sky)

Thermal conductivity overview

In order to fully grasp how filling these microscopic voids can enhance heat transfer, a clear understanding of thermal conductivity is essential. Thermal conductivity is a measure of a material's ability to transmit heat and is not dependent on the size of a given component. This parameter is generally quantified in units of power divided by area times temperature, such as W/m°C or W/m*K. It should be noted that, since one unit on the Kelvin scale is equivalent to one degree Celsius, when performing calculations, only the relative change in temperature is relevant, not the absolute value.

When dealing with heat dissipation, higher thermal conductivity is always more desirable. Low thermal conductivity materials exhibit a low rate of heat transfer, whereas materials with high thermal conductivity allow for a more rapid transfer of heat. For context, the thermal conductivity of air is merely 0.0263 W/m*K, which is approximately two orders of magnitude less than that of thermal interface materials. When there are air gaps present between the component and the heatsink, heat dissipation will be hindered. By filling these voids with a TIM, which boasts significantly greater thermal conductivity than air, more efficient heat transfer is achieved.

Thermal resistance overview

On the other hand, thermal impedance or resistance is highly dependent on the shape of a specific component and is expressed in units of temperature divided by power, i.e., degrees Celsius per Watt. While thermal resistance is covered in detail in Same Sky Overview of Thermal Management and How to Select a Heatsink blogs, here is a quick recap. Thermal resistance, denoted in units of C/W, determines how many degrees Celsius warmer a junction will become per watt of power dissipated. For instance, if a junction dissipating 4 watts of power has a resistance of 10 C/W, it will increase in temperature by 40 degrees Celsius relative to ambient temperature. Often, the thermal resistance value is quoted for a specific medium and area, such as a TO-220 package to air without a heatsink.

When several devices are integrated together, a new thermal resistance value is assigned. However, this thermal resistance value assumes that a perfect connection exists between the two surfaces, which is not always the case. In such situations, a thermal interface material is employed to create conditions as close to ideal as possible. Although this does improve heat transfer, it also adds a level of complexity since the thermal resistance of the TIM must then be included in the calculations. It might seem ironic that while the thermal interface material reduces the thermal resistance between two objects, it also possesses its own thermal resistance. This value is not insignificant, but it still reduces the thermal resistance between two objects significantly more than it adds to it. Depending on the type of TIM employed, this thermal resistance may be provided or need to be calculated based on the thickness of the TIM and the surface area over which it is applied.

Figure 2: Example of the typical thermal impedance paths that might be considered in an application. (Image source: Same Sky)

Figure 2: Example of the typical thermal impedance paths that might be considered in an application. (Image source: Same Sky)

Common types of thermal interface material

Thermal interface materials, which can take the form of gels, greases, pastes, and pads, offer diverse solutions for addressing heat management challenges. Among these, thermal interface pastes, including gels and greases, are known for their high thermal conductivity, flexibility, and ability to fill larger gaps. However, the application of paste can be complicated, particularly on uneven surfaces, and may not always produce consistent results. Over-application can lead to a reduction in overall effectiveness, while insufficient application can compromise the thermal interface's performance. Furthermore, metal-based pastes, which offer superior thermal conductivity, may create electrical hazards if they spill onto the PCB. Ceramic or carbon-based pastes can be a safer alternative, but their thermal efficiency may not be as good as metal-based options.

In contrast, thermal pads are solid TIMs made of silicone or non-silicone elastomers, with many other materials also available. For example, Same Sky thermal pads are naturally tacky, electrically isolated, and have varying thermal conductivity ratings, ranging from 1.0 to 6.0 W/m*K. One of the main benefits of using thermal interface pads instead of pastes is their ease of application. Same Sky thermal pads are pre-cut to match the profiles of their Peltier devices, which saves time and offers more convenience during assembly compared to buying large sheets of pad material and cutting them down to size. Thermal pads also provide greater consistency, less mess, and are more reusable than thermal pastes.

However, in situations where users are faced with diverse devices and sizes, thermal paste remains a preferred option due to its versatility. Thermal paste is also popular among hobbyists as it is inexpensive and readily available in small tubes, eliminating the need for precise measurements and sizing. This makes it a convenient option for small projects and one-off applications. Here is a quick summary of the different TIM options:

|

Table 1: Summary of thermal interface material options. (Image source: Same Sky)

Conclusion

Efficient thermal management is a complex problem that requires a range of strategies and solutions. It is crucial not to overlook the significance of thermal interface materials as a key component of the overall system. Whether in the prototype stage, transitioning to production, or just using thermal interface materials for DIY projects, understanding the reasons for their necessity and the mechanisms behind their functionality can make a significant difference in the thermal performance of a design.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.