Design Power for Harsh Environments Using TDK-Lambda’s PFH500 Power Modules

Contributed By DigiKey's North American Editors

2020-03-19

Due to the move to the Industrial Internet of Things (IIoT) and the emergence of 5G, electronic systems are being deployed across increasingly diverse and demanding applications. For designers of these systems, the emphasis is on power supplies that meet ever increasing reliability requirements. To meet these reliability demands, characteristics such as physical ruggedness and electromagnetic interference (EMI) mitigation are critical, as is the built-in intelligence and connectivity required to perform within the new IIoT connected paradigm.

Under this paradigm, designers can mitigate the effects of power supply and system downtime through self-diagnosis, while also allowing for remote updates, adjustments, and performance monitoring while in operation.

This article introduces a solution to these requirements in the form of TDK-Lambda’s PFH500 line of power supply modules. It shows how the power supply’s environmental design, with the addition of the PMBus, can improve power supply and system survival, and maintain performance in even the harshest of application environments.

Why use the PMBus?

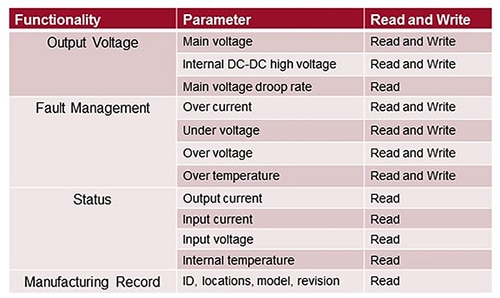

There is much that can be done with the PMBus open standard power management communication protocol for digital power management. It enhances the usage and improves performance and reliability of power supplies. For example, it enables the measurement and monitoring of various power supply parameters—such as the voltage and current on each output, temperature of each output stage, power good status of each output stage, and output enable status of each module—without any external instrumentation (Figure 1).

Figure 1: PMBus communication functions used to monitor/change parameters. (Image source: TDK-Lambda)

Figure 1: PMBus communication functions used to monitor/change parameters. (Image source: TDK-Lambda)

Users can also predict when failure will occur with continuous PMBus measurements before a catastrophic failure, which is important to applications in telecom 5G, smart factories, data centers, remote/hard-to-get-to locations, and more.

Features of the TDK-Lambda PFH500 power supply

The PFH500F series has a footprint of 4 x 2.4 inches and comes in a ¾ brick format (Figure 2). It is able to deliver 500 watts (W) of power with a regulated 28 volt output voltage that can be adjusted from 22.4 volts to 33.6 volts (±20%).

Figure 2: The PFH500F series of AC-DC power converters comes in a ¾ brick form factor and can deliver 500 W with a regulated 28 volt output. (Image source: TDK-Lambda)

Figure 2: The PFH500F series of AC-DC power converters comes in a ¾ brick form factor and can deliver 500 W with a regulated 28 volt output. (Image source: TDK-Lambda)

The design uses only one multi-layer pc board with no need for an insulated metal substrate, which reduces common mode noise and eliminates interconnecting pins, thus increasing reliability. The power architecture uses a bridgeless power factor correction (PFC) technique and synchronous rectification. Gallium nitride (GaN) power devices are used for lower losses and better efficiency, allowing it to reach 90% to 92%, with a power density of 100 W/in3. The supply is suitable for worldwide usage with an 85 to 265 VAC, 47 to 63 Hertz (Hz) input.

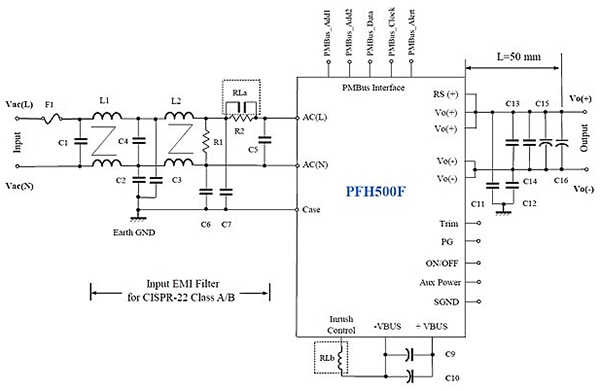

Basic connection

The basic schematic layout with external components including an external input EMI filter is shown in Figure 3.

Figure 3: Basic external connections for the PFH500F power module include an external EMI filter on the left side. (Image source: TDK-Lambda)

Figure 3: Basic external connections for the PFH500F power module include an external EMI filter on the left side. (Image source: TDK-Lambda)

This supply is a good choice for harsh environments in both traditional and smart factories as show in Figure 4.

Figure 4: The PFH500F power module meets rigorous testing requirements for harsh environments. (Image source: TDK-Lambda)

Figure 4: The PFH500F power module meets rigorous testing requirements for harsh environments. (Image source: TDK-Lambda)

Test results show passing grades for rigorous tests, especially for electrostatic discharge (ESD), radiated radio frequency interference (RFI), and electromagnetic interference immunity.

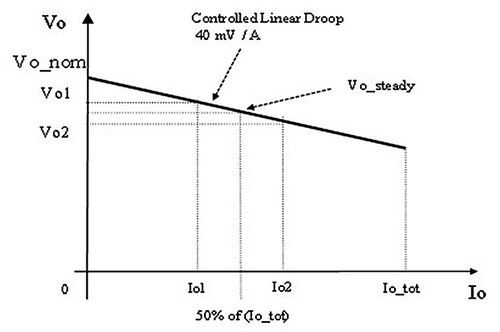

Droop share parallel capability

The extra voltage drop—or droop—in a power supply is proportional to the load drawn. When two power supplies are to be connected together to produce more power or to share the load, then a parallel-capable model such as TDK-Lambda’s PFH500 should be used. The extra voltage drop is proportional to the load drawn, so that when two or more power supplies are connected in parallel the output load is shared between the power supplies. If one of the paralleled power supplies tries to provide more current, its output will droop slightly, and the other supplies will balance out (Figure 5).

Figure 5: The Droop Mode current share option on the PFH500 allows it work in parallel with other supplies to share the load. (Image source: TDK-Lambda)

Figure 5: The Droop Mode current share option on the PFH500 allows it work in parallel with other supplies to share the load. (Image source: TDK-Lambda)

For optimal performance, all power supplies should have their outputs set to the same voltage. The PFH500’s (28 volt version) load regulation (without droop) is 28 mV, or 0.1%, with VIN = 115/230 VAC.

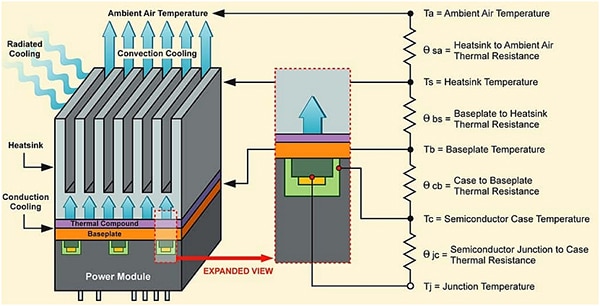

Baseplate conduction cooling capability

Conduction cooling is defined as the transfer of heat from one hot area to another cooler area by direct contact. For example, the PFH500 has a flat surface (baseplate) that is designed to mount directly to an external heatsink or cold plate that will conduct the heat away from the power device by direct contact, thereby cooling it (Figure 6).

Figure 6: A power module, such as the PFH500, is shown being cooled via conduction cooling with a heatsink (Image source: TDK-Lambda)

Figure 6: A power module, such as the PFH500, is shown being cooled via conduction cooling with a heatsink (Image source: TDK-Lambda)

For more details on cooling see, “Techniques for Cooling Power and Other Electronic Devices.”

Other benefits for designers

The PFH500 offers other benefits for designers including the following:

- Coated metal case with potting helps lower radiated emissions and improves shock and vibration capability

- Internal digital isolation (opto-isolation is not as reliable)

- Input EMI filter with surge protection prevents errors/disruption of power supply

- Internal inrush relay and circuit protects power supply from damage

- Remote sense capability enables accurate control of a voltage over a cable distance to a remote load

- Internal over-temperature and over-current protection ensures reliability

- VBUS monitoring capability protecting against over/undervoltage ensures uninterrupted operation

- In-circuit programming; for example, by a smart system

- Safety standards qualifications increase reliability

Get started with evaluation boards

Evaluation test boards are a plus since they will enable a quicker time to market. Designers will be able to obtain Gerber files for these evaluation boards from TDK-Lambda to help optimize their board layout in a system, and which can be pasted into the larger design layout of a system architecture.

There are three PFH05W evaluation test boards:

- PFH05W28-1D0-EVK-S1 evaluation kit assembly with PFH500F-28-1D0-R module

- PFH05W-001-EVK-S0 evaluation kit assembly with no power module

- PFH05W28-100-EVK-S1 evaluation kit assembly with PFH500F-28-100-R module

Each helps simplify initial evaluation of the power module for faster time to market, since they contain all the necessary external components needed for testing. Note: external airflow may be needed to cool the module heatsink when operated with a load. The TDK-Lambda HS00110 heatsink can be ordered in production quantities (Figure 7).

Figure 7: PFH05W PFH500F evaluation boards will enable faster time to market and demonstrate the performance for a designer’s particular needs. External cooling, such as the HS00110 heatsink (shown), can be added. (Image source: TDK-Lambda)

Figure 7: PFH05W PFH500F evaluation boards will enable faster time to market and demonstrate the performance for a designer’s particular needs. External cooling, such as the HS00110 heatsink (shown), can be added. (Image source: TDK-Lambda)

These three evaluation boards will need a single phase, adjustable, AC voltage source (see the separate data sheets for each board to determine the proper size for this input source), a 0 to 500 volt DC multimeter, a proper output load (refer to individual datasheets for the proper load sizes), and a fan to provide airflow to the heatsink on the board.

Note for users: Make sure all input and output cables are de-energized before making electrical connections to the evaluation test boards.

Alternative applications

This series of AC input to 28 volt output supplies can also be used in other rugged environments such as a commercial off-the-shelf (COTS) power supply for military ground vehicle platforms, or rack mounted systems such as VMEbus (Versa Module Europa or Versa Module Eurocard bus). Ion pump power supplies, which are used for such things as electron microscopes, could also benefit from the PFH500F series.

Conclusion

The PFH500F-28 series are an excellent choice for harsh environments due to fundamental characteristics, including high immunity to EMI, RFI, and other noise, as well as shock, vibration, and temperature extremes that would not be conducive to using a standard power supply. Also, their high power density, modular design, and small footprint enable a compact power supply implementation in an overall larger application.

The inclusion of PMBus allows the self-diagnosis, remote monitoring, and data communication required for the power supply’s successful integration into an IIoT predictive analysis and maintenance application.

Additional Resources

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.