Connectivity – The Backbone of Sustainable Automation

2023-08-23

Technologies such as SPE, PoDL, and Ethernet APL overcome traditional limitations of industrial communication. Advanced interfaces for signals, data, and electrical power are essential here: they help automation providers save resources and costs when networking production equipment.

(Image source: PeopleImages via Getty Images)

(Image source: PeopleImages via Getty Images)

Digitalization and seamless data networks penetrating corporate processes right down to the field level of production are a lasting trend in automation technology. Their goal is to create highly flexible production environments that can be customized to achieve an unprecedented level of diversification and productivity. For this purpose, the manufacturing industry is experiencing a disruptive transformation under the umbrella of 'Industry 4.0', with the sustainable use of all available resources being one of the most important aspects.

From field to cloud seamlessly

Seamless connectivity between machines, products, and – in the final instance – people is characteristic of this transformation, which is beginning to massively penetrate the traditional boundaries between Operational Technology (OT) and Information Technology (IT). With Industrial Ethernet, a technology is available today that can seamlessly interconnect even field-level devices via TCP/IP to companies' cloud-based data infrastructures broadband and cost-efficiently. Unlike fieldbuses, Industrial Ethernet crosses all levels of automation – end-to-end, from the field device to the cloud. Factory and plant operators can thus access device data in real time and use it for their production planning, process control, and data analysis.

The Industrial Ethernet enables, for example, the real-time acquisition and analysis of data from sensors, power supplies, or drives. Information about temperature change or vibrations at critical points as well as load profiles allow conclusions to be drawn for the optimization of process parameters. They announce when overload situations are to be expected and signal the need for maintenance at an early stage. Predictive maintenance is of particular importance here, as it helps operators to improve the availability of their plants and machines, as well as to minimize energy consumption and use of resources – which, on the one hand, lowers operating costs but, on the other hand, makes a decisive contribution to the sustainability of process and factory plants.

Rugged RJ45 alternative

The physical backbone of these networks, particularly of Industrial Ethernet, is high-performance interconnect technology that allows for reliable transmission of signals and data between the various nodes of the automation networks. In addition to the physical robustness they require in industrial use, such solutions face a number of new challenges today, resulting, for example, from the sheer quantity of network nodes, their miniaturization, or the high transmission bandwidth. These include, in particular, compact form factors, reduced installation and cabling effort, high signal integrity – i.e., sophisticated shielding against electromagnetic interference – and reliability over long transmission distances. The latter is particularly relevant in extended plant fields. Increasingly, the power supply of devices using data connectors is also required.

The standard interface for Ethernet communication is the widely used RJ45 connector. Users frequently report problems with the contacts or broken latching elements; RJ45 also limits miniaturization due to its size. In contrast, alternatives such as the ix Industrial interface from German supplier HARTING (Figure 1) are substantially smaller and much more robust, particularly resistant to shock and vibration. According to the manufacturer, space savings of up to 70% on the circuit board are possible compared to standard RJ45. The 360°-shielded connector is designed for 10-Gbit/s Ethernet communication and is compatible with PoE (Power-over-Ethernet) as well as PoE+ for power transmission.

Figure 1: Considerably smaller and more robust than standard RJ45 connectors: HARTING's industrial Ethernet interface ix Industrial. (Image source: HARTING)

Figure 1: Considerably smaller and more robust than standard RJ45 connectors: HARTING's industrial Ethernet interface ix Industrial. (Image source: HARTING)

ix Industrial is an interface developed by HARTING in conjunction with Japanese connector specialist Hirose. Its dimensions, electrical properties, and coding comply with the IEC 61076-3-124 standard. Other manufacturers, such as the US company Amphenol Communications Solutions, also offer products with comparable properties that are intermateable with ix Industrial: for example, push-pull connectors for harsh environments in protection degrees IP65/66/67, ix Mag connectors featuring integrated magnets (Figure 2), or Ethernet-to-RJ45 cable assemblies with angled RJ45 connectors; they provide both 100-Gbit Ethernet and PoE/PoE+ functionality.

Figure 2: Amphenol ix Mag: Ethernet communication up to 10 Gbit/s, 360° shielding and PoE++ up to 90 W (Image source: Amphenol Communications Solutions)

Figure 2: Amphenol ix Mag: Ethernet communication up to 10 Gbit/s, 360° shielding and PoE++ up to 90 W (Image source: Amphenol Communications Solutions)

ix Industrial use case

The following example illustrates the enormous potential of high-performance, miniaturized Ethernet interfaces for Industry 4.0 applications:

The XTS linear transport system from automation specialist Beckhoff is a drive solution that uses magnetically driven movers traveling along a track of fully integrated motor modules. According to Beckhoff, their independent control allowing for individual motion profiles is the starting point of new machine concepts that enable more flexible manufacturing processes with shorter downtimes, such as retooling.

In order for the movers to follow their movement pattern, a computer must constantly calculate the switching and current supply of the respective motor modules. For this purpose, a total of three computer boards can be combined, each of which previously had four RJ45 sockets as ports. To allow more movers to be operated in the latest generation of the XTS system without having to change the dimensions of the system, the RJ45 sockets were replaced by the ix Industrial interface from HARTING. Reliable shielding and high data throughput were the main requirements here. Unlike RJ45, each ix Industrial connector allows for two 100-Mbit/s Ethernet connections. Thus, eight instead of four ports could be mounted on the same board, and two Ethernet channels could be installed per port instead of one.

As a result, 48 instead of twelve ports were implemented on the three computer boards. Accordingly, with the latest XTS generation, 48 instead of twelve XTS lines can now be used per unit, corresponding to a 400-% increase in the performance of the transport system.

Two wires – instead of four or eight

One distinctive attribute of today's industrial automation technology is its migration from hierarchical to decentralized architectures. These are considered advanced and particularly productive and, moreover, promise increased network security. This is because intelligent nodes such as smart sensors or edge computers, which are capable of performing certain data processing tasks autonomously, reduce sensitive data traffic between the edge and the cloud. The advantages of decentralization are self-evident, but the number of connected devices in the field is growing enormously, and so are the efforts for cabling and connectivity. Their economic use, both in terms of material and installation effort as well as energy consumption, is becoming a strong criterion for the sustainability of manufacturing facilities.

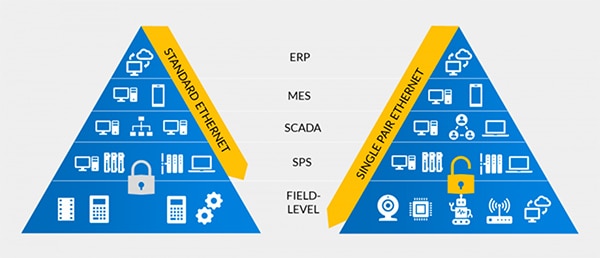

Single-Pair Ethernet (SPE) is considered a decisive breakthrough in efficiency and cost-effectiveness. The communication technology is defined by the IEEE 802.3 standard; the IEC 63171-x series of standards applies to the respective connectors. Essentially, it enables field components to be connected via just one twisted pair, i.e., two wires instead of the previous four or even eight: low-cost, resource-efficient, and therefore extremely sustainable. Originally developed for automotive electronics, SPE meets the requirements of many automation providers: The single pair of wires enables them to integrate a large number of instruments, controllers, and other devices into Ethernet networks at gigabit data rates (Figure 3).

Figure 3. Single-Pair Ethernet allows for resource- and cost-efficiently integrating the field level into broadband Ethernet communication. (Image source: SPE Industrial Partner Network)

Figure 3. Single-Pair Ethernet allows for resource- and cost-efficiently integrating the field level into broadband Ethernet communication. (Image source: SPE Industrial Partner Network)

Another advantage: thanks to PoDL compatibility (Power-over-Data-Line, IEEE P802.3bu), the same pair of wires is able to deliver not only data but also electrical power to the field devices. In addition to actuators and sensors, in the power range of the previous PoE supply, camera-based instruments can be connected and powered via PoDL, for example.

Products for Single-Pair Ethernet

In the SPE segment, HARTING is taking a position with its T1 connector, including locking and 360° EMI shielding (Figure 4). The PoDL-capable T1 is available in circular designs, including M8 and M12. In terms of protection degrees, the product spectrum ranges from IP20 to IP67, and according to the manufacturer, the respective interface counterparts are designed to meet the protection classes and ensure interoperability.

Figure 4: Shielded and equipped locking functionality – the PoDL-compatible T1 is offered for protection degrees IP20 to IP67. (Image source: HARTING)

Figure 4: Shielded and equipped locking functionality – the PoDL-compatible T1 is offered for protection degrees IP20 to IP67. (Image source: HARTING)

Phoenix Contact also provides a comprehensive SPE portfolio for field cabling to and from control cabinets, sensors, switches, and gateways. This supplier's products include, for example, board connectors or cable assemblies for use in industrial IP20 to IP67 environments.

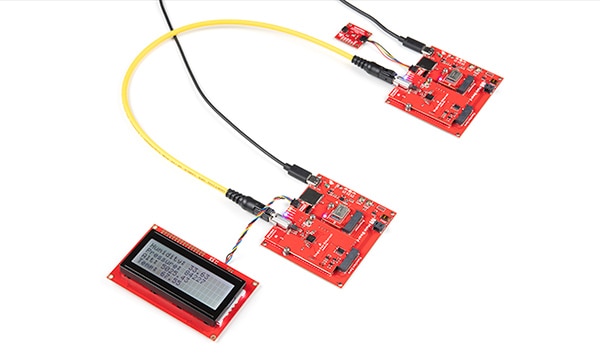

The open-source tool provider SparkFun Electronics offers an SPE function board to support developers in designing applications with Single-Pair Ethernet (Figure 5). The board, called MicroMod COM-19038, includes an ADIN1110 Ethernet transceiver from Analog Devices, passive components from Würth Elektronik, and a HARTING T1 connector. An integrated MAC (Media Access Control) interface enables serial communication with a host controller at 10 Mbit/s in full duplex mode. The board supports network nodes via 1700 m cable lengths, but it is not designed to supply power to the nodes via this cable. Kirk Benell, CTO of SparkFun, presents the development board in a demo video.

Figure 5: Demonstrator for an ambient sensor featuring a display. (Image source: SparkFun Electronics)

Figure 5: Demonstrator for an ambient sensor featuring a display. (Image source: SparkFun Electronics)

End-to-end networking in process technology

The technical advantages of Single-Pair Ethernet, for example, concerning condition monitoring and predictive maintenance, are also beneficial for process automation. However, an extended requirements profile for Ethernet connectivity applies here. In addition to robust and broadband real-time communication, as it is also required on a shopfloor, wide-ranging process plants require data transfer over long distances. Furthermore, automation components must be intrinsically safe for use in potentially explosive environments. This is where the so-called Ethernet Advanced Physical Layer (Ethernet APL) enters the scene: it defines a physical transmission layer for Ethernet communication at 10 Mbit/s as well as for power supply via one twin wire – as with SPE – over distances of up to 1000 m. Like SPE, Ethernet APL is perfectly suited for universal, multipurpose field instrumentation.

Summary

Industrial Ethernet, and particularly Single-Pair Ethernet, support broadband networking of production equipment. They enable seamless communication from the field level to the cloud and allow real-time access to device data, which supports operators in plant and process optimization. Their benefits are clearly evident in reduced operating costs, higher availability, and optimized use of energy and resources. Advanced connection technologies such as ix Industrial interfaces and SPE connectors with PoDL capability ensure reliable data and power transmission between all network nodes. This makes them key components of Industry 4.0 and a backbone of sustainable automation concepts.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.