Choosing Thin-Film Resistors for Automotive and Industrial Applications

Contributed By DigiKey's North American Editors

2025-03-05

Electronic applications such as automotive, industrial, and telecommunications require precision components that tolerate harsh environments, including high humidity and erosive atmospheres. Passive components are fundamental to the success of these advanced designs and require constant innovation to ensure reliable performance.

For example, metal film chip resistors must be designed and tested to ensure accuracy, stability, and reliability in challenging environments. One significant issue affecting the design of chip resistors for the automotive and industrial markets is their long-term reliability in the presence of sulfur compounds. These environments, where oils, lubricants, fuel, and other sulfur-rich compounds are extant, can degrade contacts and reduce the reliability of chip resistors.

This article discusses the challenges facing designers when choosing resistors for harsh automotive and industrial environments. It then presents two families of sulfur and moisture-resistant surface-mount resistors from YAGEO and shows how they can be used to meet the challenges of these applications.

Chip resistor characteristics

Chip resistors are a key component in modern electronics, including automotive, industrial, and telecommunication devices. Their small size, accuracy, stability, and reliability fit perfectly into high-density circuits. They come in a wide range of resistances, tolerances, temperature coefficients of resistance (TCRs), and power ratings. Two YAGEO chip resistor families are the AT and RP series. Both series are rated for automotive applications with AEC-Q200 qualification; this specification tests passive electronic components for temperature, humidity, resistance to soldering heat, thermal shock, and board flex tolerance. It also tests for low moisture sensitivity and sulfur resistance.

Comparing electrical specifications

The AT and RP series of surface-mount device (SMD) resistors are available in four standard surface-mount packages: 0402, 0603, 0805, and 1206. The numerical code for each package contains the device's nominal length and width in inches (Table 1).

|

Table 1: Shown are the dimensions and power ratings for the four package sizes of the RP and AT chip resistor series components. (Table source: Art Pini)

The power ratings vary directly with the package volume, ranging from 1/16 W to 1/4 W.

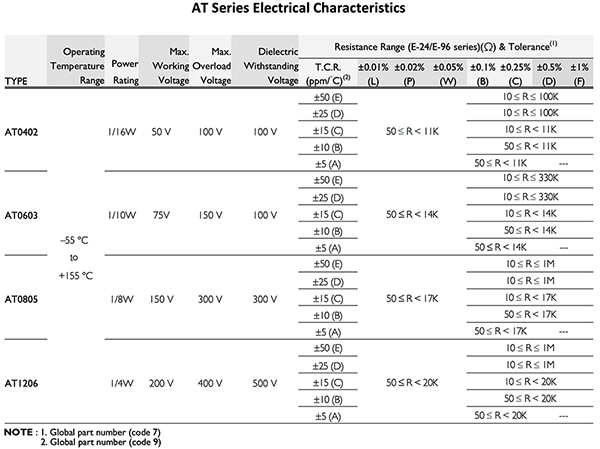

These package sizes offer varied values of resistance, resistive tolerance, TCR, and voltage ratings. The specifications of the AT series resistors are summarized in Table 2.

Table 2: Shown are the electrical characteristics of the AT series resistors. (Table source: YAGEO)

Table 2: Shown are the electrical characteristics of the AT series resistors. (Table source: YAGEO)

The table lists the available range of resistor values for each package size, TCR, and tolerance.

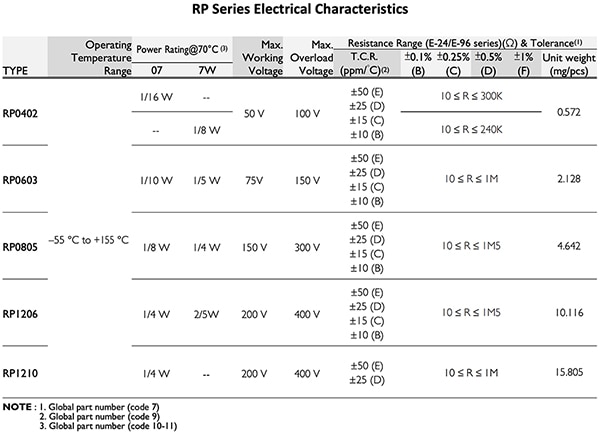

Similarly, the specifications for the RP series are summarized in Table 3.

Table 3: Shown are the electrical characteristics of the RP series resistors. (Table source: YAGEO)

Table 3: Shown are the electrical characteristics of the RP series resistors. (Table source: YAGEO)

Components of either product series are selected based on package size, TCR, resistance tolerance, and resistance. The range of available resistance values varies with each of the other specifications.

The TCR values for the RP series are available in steps of ±50, ±25, ±15, and ±10 parts per million per degree Centigrade (ppm/°C). The AT series adds an additional lower TCR of ±5 ppm/°C.

Note that the range of available resistance values for the RP series devices is greater or equal to those of the AT resistors for each TCR step.

Both series offer tolerance values of 0.1%, 0.25%, 0.5%, and 1%, which are the most used resistor tolerances. However, the AT series offers three additional tolerance ranges: 0.05%, 0.02%, and 0.01%. These precise tolerances are less frequently called for, and the resistor values offered have a more restricted range.

Comparing the AT and RP series resistors

The YAGEO AT0402FRE0710KL is a 10 kiloohm (kΩ), 1/16 W AT series resistor with a TCR of ±50 ppm/°C in an 0402 package. The RP series equivalent is the RP0402FRE0710KL, which has the same specifications. The difference in products is that the RP series offers resistance values of 10 Ω to 240 kΩ in this TCR range compared to the AT series range of 10 Ω to 100 kΩ. The RP series provides this range of resistance over all the TCR values, whereas the AT series reduces the range for TCR values of ±10 ppm/°C and ±5 ppm/°C.

The AT0603DRE0710KL is a 10 kΩ, 1/10 W AT series resistor in an 0603 package. Its TCR is ±50 ppm/°C. The RP0603DRD0710KL is an RP 0603 series resistor with the same nominal specifications except for the TCR, which is ±25 ppm/°C. The range of available resistances in the RP series is from 10 Ω to 910 kΩ. The AT resistors have values ranging from 10 Ω to 330 kΩ for the two highest TCR specifications and a much more restrictive range for the lower TCR selections.

In an 0805 package, the AT series AT0805BRD0710KL is a 10 kΩ, 1/8 W resistor with a TCR of ±25 ppm/°C. The equivalent RP entry, the RP0805BRD0710KL, has the same resistance, tolerance, and TCR. Again, the RP series has a broader resistance range over the full range of TCR selections, while AT resistors have a more restricted range for the lower three TCR selections.

The AT1206BRD0710KL is a 10 kΩ, 1/4 W resistor in a 1206 package. Its RP equivalent is the RP1206BRD0710KL, with identical specifications.

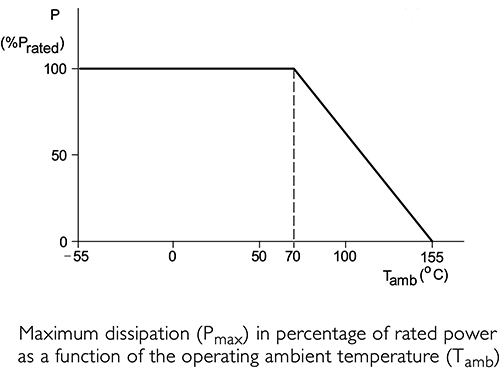

Based on the electrical specifications, these resistor families are similar and would fit into many applications. The RP series offers a broader range of resistance values, making it more applicable. The AT series offers closer tolerances for some resistance values and a lower TCR range, and both of these characteristics would be applied in applications requiring greater precision and accuracy. Both series operate over a temperature range of -55°C to +155°C for their rated power levels. Note that the rated power must be derated if the ambient temperature rises above +70°C (Figure 1).

Figure 1: The power derating curve for both series requires reduced power at temperatures above 70°C. (Image source: YAGEO)

Figure 1: The power derating curve for both series requires reduced power at temperatures above 70°C. (Image source: YAGEO)

Environmental safety and protection

Both the AT and RP product families are qualified for use in automotive and industrial environments. The epoxy compounds used in their manufacture are halogen-free. Additionally, they are lead-free and meet RoHS specifications. These resistors also reduce environmentally hazardous waste production by using non-forbidden materials.

Both resistor product lines have low susceptibility to moisture and corrosive gases common in vehicular and industrial conditions. One aspect of moisture resistance is the moisture sensitivity level (MSL). This rating system used by the electronics industry identifies how long a component can be exposed to a humidity level of 60% to 85% relative humidity, and at a temperature below +85°F before it absorbs too much moisture to be wave soldered. During wave soldering, trapped moisture expands rapidly, damaging the component and possibly the circuit board. The AT and RP series resistors are rated at MLS 1, indicating an unlimited floor storage life. They are also tested for moisture resistance under AEC-Q200, and both series have variations in resistance of less than ±(0.1% + 0.05 Ω) due to exposure to humidity.

Contamination due to exposure to sulfur compounds is an increasing area of sensitivity for passive components like chip resistors. Oil, lubricants, oil-based fuels, and rubber components or coatings emit sulfur-based fumes. These sulfur compounds react with metals, especially silver, and can damage chip resistors.

The test (ASTM-B-809-95, modified) for sulfur resistance involves exposing test components to a sulfur-rich atmosphere created in a closed vessel by adding a measured amount of powdered sulfur. The vessel is heated to +105°C, and the components are exposed to this atmosphere for 750 hours. The resistors under test are measured to ensure their resistance changes less than a prescribed limit. Both series of resistors exhibit superior resistance to sulfur.

Differences between the AT and RP series resistors

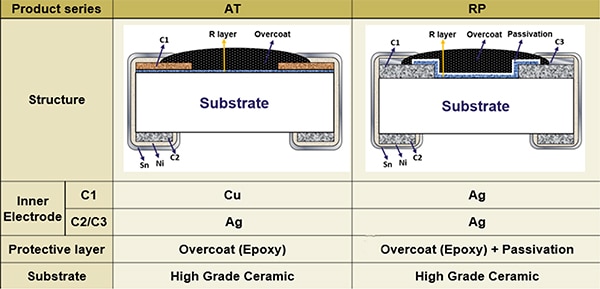

The AT and RP series resistors have different designs. The AT series is an earlier design that uses a more traditional approach to moisture and sulfur resistance. The RP series is a more recent design incorporating newer construction techniques and materials (Figure 2).

Figure 2: A comparison of the construction of the AT and RP series chip resistors shows the differences in how the devices are protected from moisture and sulfur. (Image source: YAGEO)

Figure 2: A comparison of the construction of the AT and RP series chip resistors shows the differences in how the devices are protected from moisture and sulfur. (Image source: YAGEO)

Both series use a resistive metal film deposited on a ceramic substrate like all chip resistors. The AT resistors use copper as the top side electrode (C1) to reduce the corrosive effects of sulfur vapors, as copper’s reaction with sulfur is not as strong as silver’s. The resistive layer and the electrode are sealed using an epoxy overcoat. The end caps are made of tin-coated nickel to ensure solderability. They seal and provide connection points to the silver electrode on the bottom of the resistor.

Based on years of experience with related chip components, the RP devices add a polymer silver layer (C3) on top of the C1 inner electrode to prevent sulfur contamination. This allows the inner electrodes to be made of silver. A thin passivation layer is a barrier between the metal film and corrosive elements. Passivation is a chemical process that coats the resistive layer to make it less likely to corrode or be affected by its environment. An epoxy overcoat completes the sealing process.

The RP series has better sulfur resistance than the AT series due to its improved sealing process. The sulfur test specification for the RP devices has a tighter limit of ±(2.0% + 0.05 Ω) compared with the AT limits of ±(4.0% + 0.05 Ω). This means a smaller change in resistance due to sulfur exposure.

The newer resistor structure has also improved production efficiency, with lower costs and shorter lead times.

Conclusion

Automotive, industrial, and telecommunications systems require precision components that can reliably perform in harsh environments, including high humidity and erosive atmospheres. The AT and RP series resistors are AEC-Q200 qualified and well-suited to these applications. The RP series has improved humidity and sulfur tolerance, lower pricing, and shorter lead times. The AT series offers selective resistor values with lower tolerances of ±0.01%, ±0.02%, and ±0.05%.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.