Choosing the Right Capacitor Technology for an Application

Contributed By DigiKey's North American Editors

2024-05-01

Choosing the right capacitor for an application can make a significant difference in the performance, reliability, and efficiency of products such as power supplies for defense, aerospace, medical technology, critical energy infrastructure, or fast EV chargers.

Capacitors are essential components in many electronic circuits as they store and release electrical energy, filter out unwanted signals, and perform other functions. However, not all capacitors are created equal, and different types of capacitors have varying characteristics, advantages, and limitations.

Selecting the right capacitor type is crucial in product design. Three common options—multilayer ceramic capacitors (MLCCs), film, or aluminum electrolytic—offer advantages and disadvantages, and there are myriad variations within each category. Choosing the right type ensures the final product has enough energy storage, fits in the available space, and functions reliably for its intended use.

The case for MLCCs

MLCCs consist of alternating layers of ceramic dielectric and metal electrodes stacked and sintered together to form a compact package. Widely used in many electronic devices, MLCCs provide high capacitance values in small sizes, low equivalent series resistance (ESR), low leakage current, high frequency response, and good temperature stability.

MLCCs are suitable for applications that require high power density, high efficiency, low noise, and high reliability. However, there are variations among this category that can make a difference in developing successful products:

- High Reliability MLCCs: Offer high reliability, low failure rate, long life, and high performance under harsh conditions. These characteristics are important in meeting stringent requirements of industries such as aerospace and defense, including specifications under MIL-PRF-55681, MIL-PRF-123, MIL-PRF-49470, and MIL-PRF-39014, as well as medical applications.

- High Voltage MLCCs: Operate at voltages above 500 V and up to 12 kV. They are designed for applications that require high voltage isolation, such as power supplies, pulse generators, and X-ray equipment. They feature high capacitance, low ESR, low dissipation factor, and high breakdown voltage.

- High Temperature MLCCs: Operate at temperatures above +125°C, up to +250°C. They are designed for applications that require high temperature stability, such as down-hole drilling, automotive, and industrial. They provide high capacitance, low ESR, low temperature coefficient, and high thermal shock resistance.

Advantages of film capacitors

Film capacitors are suitable for applications that require high power, high current, high voltage, and high frequency, such as power conversion, filtering, snubbing, and coupling. These capacitors consist of a thin film of dielectric material—such as polyester, polypropylene, polycarbonate, or polyphenylene sulfide—sandwiched between two metal electrodes, either wound into a cylindrical shape or stacked into a flat shape.

Film capacitors are often larger and more expensive than MLCCs, but they provide high capacitance values, high voltage ratings, low ESR, low dissipation factor, high frequency response, and long life. Advantages of this technology include higher voltage ratings, linear capacitance change with voltage and temperature, no piezoelectric noise, self-healing capability, and long life.

There are several categories of film capacitors that can impact which is right for an application:

- Metallized polyester film capacitors use a thin layer of metal, such as aluminum or zinc, deposited on the polyester film as the electrodes. They offer high capacitance, low ESR, low cost, and good self-healing properties. They meet the needs of general-purpose applications such as bypass, coupling, and decoupling.

- Metallized polypropylene film capacitors utilize polypropylene film as the electrodes with a thin layer of metal, such as aluminum or zinc. They are characterized by high capacitance, low ESR, low dissipation factor, high frequency response, and high stability. They are suitable for high performance applications, such as power factor correction, filtering, and snubbing.

- Polycarbonate film capacitors use a polycarbonate film as the dielectric material. They offer high capacitance, high voltage rating, low temperature coefficient, and high reliability. These are appropriate for applications that require high temperature stability, such as timing, sensing, and precision circuits.

- Polyphenylene sulfide film capacitors use polyphenylene sulfide film as the dielectric material. They offer high capacitance, high temperature rating, low ESR, low dissipation factor, and high frequency response. Suitable applications include those that require high temperature performance, such as automotive, industrial, and telecom.

- Metallized paper film capacitors rely on metallized paper film as the dielectric material. They offer high capacitance, high voltage rating, low ESR, low dissipation factor, and high self-healing properties. They are suitable for applications that require high voltage isolation, such as power supplies, pulse generators, and X-ray equipment.

Aluminum electrolytic capacitors

Aluminum electrolytic capacitors are suitable for applications that require high capacitance, high voltage, and low frequency, such as smoothing, filtering, and energy storage.

With the ability to store large amounts of electrical energy for its size, an aluminum electrolytic capacitor is applicable for smoothing power supplies in electronic devices. They may have a shorter lifespan than MLCCs and film alternatives, and because they are polarized with a positive and a negative terminal, can be damaged if installed backwards. They also may continuously leak a small amount of current and are not as stable at high frequencies compared to alternatives.

Aluminum electrolytic capacitors are available in various electrolyte types, such as liquid, solid, or hybrid, which have different performance, stability, and reliability characteristics:

- Liquid aluminum electrolytic capacitors use a liquid electrolyte solution as the cathode. They offer high capacitance, high voltage rating, and low cost. However, they also have high ESR, high leakage current, high dissipation factor, and limited life. They are suitable for general purpose applications, such as smoothing, filtering, and energy storage.

- Solid aluminum electrolyte capacitors have a solid electrolyte material — such as manganese dioxide or conductive polymer — for the cathode. They offer low ESR, low leakage current, low dissipation factor, and long life. However, they also have lower capacitance, lower voltage rating, and higher cost than liquid electrolyte capacitors. They are suitable for high performance applications, such as switching power supplies, LED drivers, and audio amplifiers.

- Hybrid aluminum electrolytic capacitors use a combination of liquid and solid electrolytes as the cathode. They offer a balance of capacitance, voltage rating, ESR, leakage current, dissipation factor, and life. They are suitable for applications that require high power density, high reliability, and high temperature performance, such as automotive, industrial, and telecom.

Supplier acquisition broadens capacitor portfolio

Knowles and Cornell Dubilier Electronics (CDE) are two leading manufacturers of capacitors, offering a wide range of capacitor technologies and products. Knowles acquired CDE in 2023, combining complementary strengths of both companies, including CDE's film capacitors and aluminum electrolytic capacitors, and Knowles Precision Devices’ film and MLCCs.

Knowles offers a comprehensive portfolio of MLCCs in standard surface mount packages and ribbon or radial lead packages, ranging from under a picofarad to hundreds of microfarads, with ratings from 6.3 V to 12 kV. Knowles MLCCs are available in various dielectric materials with different temperature coefficients, dielectric constants, and aging rates.

Knowles' FlexiCap™ manufacturing approach utilizes a proprietary flexible epoxy polymer termination material applied under the usual nickel barrier finish that accommodates a greater degree of board bending than conventional capacitors. Its StackiCap™ range provides significant reduction in PCB real estate for an equivalent capacitance value in cases where board space is at a premium; for example, a standard 150 nanofarads (nF) chip in an 8060 case size is available in a much smaller 3640 case size.

The Knowles Syfer 2220Y5000564KXT (Figure 1) is a FlexiCap surface mount MLCC that can store 0.56 microfarads (µF) of electrical charge—with a tolerance of ±10%—and is designed to handle up to 500 V. It is one part of a product family of DC rated MLCCs that range from 0.2 picofarads (pF) to 22 µF and in case sizes from 0402 to 8060.

Figure 1: A representation of the Knowles Syfer 2220Y5000564KXT. (Image source: Knowles)

Figure 1: A representation of the Knowles Syfer 2220Y5000564KXT. (Image source: Knowles)

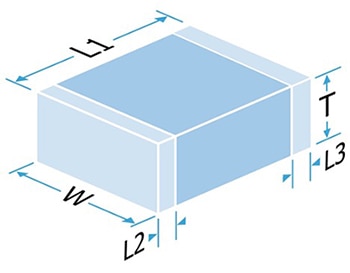

The Knowles Syfer 2220Y6300105KETWS2 (Figure 2) is a StackiCap MLCC that can store 1 µF of electrical charge, with a tolerance of ±10%, and is rated for 630 V.

Figure 2: Illustration of StackiCap packaging for Knowles Sifer 2220Y6300105KETWS2 and similar MLCCs. (Image source: Knowles)

Figure 2: Illustration of StackiCap packaging for Knowles Sifer 2220Y6300105KETWS2 and similar MLCCs. (Image source: Knowles)

Knowles CDE offers a wide selection of standard and custom screw terminal, snap-in, and board mount capacitors for use in critical applications, ranging from defibrillators and medical imaging, to radar systems and UPS power backup for large data systems.

CDE's 477XMPL002MG19R is part of the XMPL polymer chip capacitor series for applications requiring higher voltage and/or capacitance requirements. With low ESR and robust ripple current ratings, they outperform surface mount electrolytics of greater size and provide longer life, greater stability with temperature changes, and lower ESR at higher frequencies. Standard capacitance values of the series now range from 6.8 µF to 470 µF, with a maximum working voltage of 35 VDC in a molded package measuring 7.3 mm x 4.3 mm x 1.9 mm.

Among an extensive range of film capacitors, CDE's Type FCA acrylic film capacitors like the FCA0805C104M-J2 offer high capacitance values in standard surface mount case sizes. The series offers a capacitance range of 0.10 µF to 1.0 µF. As coupling capacitors in audio circuits, they can yield distortion-free sound and high frequency filtering.

Conclusion

Capacitors are vital electronic components, and selecting the right one is crucial in product design. Fortunately, Knowles and Cornell Dubilier Electronics provide access to a vast selection of common types with multiple variations, as well as special types designed for specific applications.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.