Automating Terminal Block Wiring Requires Advanced Connectors

Contributed By DigiKey's North American Editors

2024-04-18

Investments in automation, electrification, and digitization rely on dependable power. However, the complications of hand-wiring control cabinets and the potential for human error can result in highly inefficient and time-consuming processes. Automating, or at least simplifying, wiring connectivity is essential for increasing reliability and cabinet maker profitability.

Cabinet builders and product designers must account for the complexities of electrical interconnections and associated manufacturing processes, along with the long-term behavior of electrical contacts and reliability requirements. At the heart of the control cabinet are the terminal blocks that connect and control wires in an electrical system. They are essential for organizing and testing the wiring and components, often utilizing industry-standard DIN rails.

Control cabinets are crucial to various industrial and commercial building applications. They must accommodate varied power requirements and isolate heat-generating and noise or vibration-prone components. Some cabinets may house programmable logic controllers and sensors, and frequently intermix data communications lines with electrical wiring.

Product designers are called on to squeeze more components—from signaling devices to power supplies—into cabinets with strict footprint limitations that must often withstand harsh environmental conditions. Installation work for control cabinet construction must be carried out ever faster and preferably automated to increase productivity and profitability, but terminal block connections should be permanently reliable, safe, and easy to maintain.

To meet future needs, these cabinets must be field-upgradeable and adaptable to new wiring and technology adoption. Efficient, easy wiring is a primary ingredient for increasing efficiency in cabinet design, assembly, installation, and, ultimately, robotic assembly.

Improving terminal blocks

Wiring connections must be reliable, safe, and easy to maintain, but wiring a cabinet can be complex and time-consuming. A study by the Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW) estimated that the average control cabinet houses 500 wires, which requires an average of 54 hours for wiring, 56% of which is expended on cutting, adding connectors, and crimping.

Terminal blocks simplify the wiring process and make it easier to arrange and rearrange modules within the cabinet. But many producers and customers still rely primarily on physical labor to complete terminal block connections using one of three types of connections to secure the wire conductors:

- Screw connections, with either clamping yoke or bolt connections. These are particularly suitable for connections with large conductor cross-sections. Proven and reliable, these may need periodic tightening. Over-tightening is a potential risk that could damage the wiring.

- Spring connections into which stripped solid conductors are simply inserted into a self-locking, spring-activated, tension clamping point. However, they require the insertion of a tool to open the clamping point.

- Push-in connections, an enhancement to spring-activated tension clamp connections, provide greater convenience and contact reliability. Assemblers and installers can take a stripped, fine-stranded conductor with a crimped-on ferrule or a solid conductor and simply insert it into the clamping point up to the stop without needing a tool. In addition to the frequent use of ferrules, opening the clamp to remove conductors still requires using a tool.

A SNAP IN connection option

Weidmüller offers another option, going beyond push-in connections. The company's Klippon Connect SNAP IN terminal blocks promise easier, faster, safer, and more efficient electrical connectivity. This technology can reduce connection times for terminal blocks by up to 50% and even support fully automated wiring processes.

Even flexible conductors can be connected without ferrules or tools. SNAP IN S-series feedthrough and protective earth (PE)/grounded terminal blocks incorporate a pre-loaded spring, and stripped wires can be quickly and safely inserted into the clamping point without further preparation. Contact with the clamping point is signaled with a clear “click” sound, and a green pusher is raised to provide visual confirmation. Reliable contacting of the conductor ensures the wire connection is protected against vibration, as well as being gas-tight and stable.

With the SNAP IN terminal blocks, conductor wires can be quickly released by pressing the pusher, which also pre-loads the clamping point for subsequent insertion. Producers can speed up wiring times with reduced wire preparation and create a more efficient installation process.

The conductor connection lever of SNAP IN terminal blocks is already open, allowing the stripped connector to be inserted, upon which the patented clamping mechanism closes automatically. This ensures a safe, self-locking, permanent connection with a high contact force from the conductor to the busbar.

In cases where a stripped conductor end needs to be protected, manufacturers and installers can use ultrasonic welding or crimped ferrules. Standardized test points enable automated testing and checking processes.

Correctly inserted SNAP IN connections are stable over the long term and suitable for areas subject to vibration and shock, according to IEC 61373/10.2011. Subsequent checking or readjustment is unnecessary. Furthermore, SNAP IN connections are trouble-free, even at extreme temperature ranges from -40°C to approximately +120°C.

SNAP IN terminal blocks are “ready to robot,” with an optimized design that can be terminated directly with robotic systems. Automated terminal block connection can prevent production errors, speed up workflows, and reduce costs.

The SNAP IN S-Series terminal blocks have been optimized for automated laser marking to further reduce production time.

SNAP IN S-Series options

Feed-through terminal blocks are suitable for joining and/or connecting one or more conductors. They could have one or more connection levels that are on the same potential or insulated against one another.

Weidmüller SNAP IN S-series feed-through terminal blocks are available in single-tier versions with 2, 3, or 4 connections. Figure 1 shows the 2-connection 2674530000 and the 4-connection 2753960000. A 3-connection 2753950000 is also available. Each block accommodates conductors with a cross-sectional area of up to 2.5 mm2 and the American Wire Gauge (AWG) standard range of 14-20.

Figure 1: Left is the 2-connection, single-tier 2674530000 feed-through terminal block connector, and on the right is the 4-connection, single-tier 2753960000. (Source: Weidmüller)

Figure 1: Left is the 2-connection, single-tier 2674530000 feed-through terminal block connector, and on the right is the 4-connection, single-tier 2753960000. (Source: Weidmüller)

Weidmüller also offers multi-tier, stacked connectors that can accommodate more conductors in compact spaces, including the 4-connection 2902380000 (Figure 2).

Figure 2: The 4-connection, double-tier 2902380000 feed-through terminal block connector. (Source: Weidmüller)

Figure 2: The 4-connection, double-tier 2902380000 feed-through terminal block connector. (Source: Weidmüller)

Protective earth (PE)/ground terminal blocks are a type of feed-through terminal block that provides a reliable earth ground connection to mounting points. They have one or more contact points for connection with and/or bifurcation of protective earth conductors.

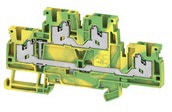

PE versions in Weidmüller’s SNAP IN S-series include the single-tier, 2-connection 2674560000, and the multi-tier 4-connection 2902460000 (Figure 3).

Figure 3: The 4-connection, double-tier 2902460000 PE block connector. (Source: Weidmüller)

Figure 3: The 4-connection, double-tier 2902460000 PE block connector. (Source: Weidmüller)

Terminal block wiring also requires an end plate, such as the Weidmüller 2751080000. It is fitted to the open side of the last modular terminal before the end bracket to ensure the function of the modular terminal and the specified rated voltage, and to protect against contact with live parts.

Conclusion

Efficient, easy wiring is key to meeting the demand for electric control cabinets as the pace of electrification and automation increases. The self-activating connection mechanism of Weidmüller’s SNAP IN technology provides opportunities for greater productivity with easier-to-assemble and maintain terminal block connectors that can be more readily reconfigured, and that are optimally designed to support robot-assisted assembly.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.