AEC-Q200 Qualified Fuses Play a Critical Role in the Automotive Environment

Contributed By DigiKey's European Editors

2023-10-12

Fuses have been used as essential protective devices since the dawn of electrical lighting in the late nineteenth century. They protect devices from faults such as short-circuits occurring at a load by interrupting the flow of electric current. This interruption can protect wiring, electronic devices, and the load from catastrophic damage. Therefore, fuses can minimize the fault condition risk of injuries to people and property.

The protection fuses provide is especially beneficial to the growing automotive market and the rising demand for electric vehicles (EVs). With EV power conversion and the ever-increasing number of electronic systems, circuit protection has become an imperative to safeguard the myriad of devices present in an EV.

Automotive fuses

The typical automotive fuse works by melting a conductive link. An electric arc follows, turning the link into an open circuit. The current pulse (magnitude, shape, and time), the ambient temperature, and the characteristics of the fuse determine the temperature within the fuse element at which this occurs. The time-current curve (called TCC) at different rated fuse currents helps determine the interrupt time at a given current. This, along with the melting energy (I2 x t, where I is the current and t is the time), helps determine a suitable fuse for the application. Automotive fuses have evolved to meet the changing needs of the industry. In the 1960s, glass tube fuses were commonly used. More compact blade fuses are the most used today. Most of these are fast responding (in a few milliseconds), which is good to prevent damage to sensitive electronics, but not for motors due to the high inrush current at start-up. Slow blow fuses have been developed for this application, where the response time can be in the order of several seconds. Some of the other characteristic requirements for fuses used in automotive applications include:

- Higher voltages of up to 800 V for the changing bus are expected soon. For this reason, ratings exceeding 1,000 V will be required, with great attention given to the arc discharge created at these voltages to prevent circuit damage.

- High reliability due to the risk of catastrophic accidents due to failure.

- Large range of ambient temperature. Fuses used in the engine compartment can face temperatures ranging from -40˚C to +150˚C or wider.

- Size, weight, and form factor are key minimization goals for all components used in an EV, driven by the need to increase vehicle performance and range for a given battery charge.

- Vibration resistance is a key requirement due to varied road conditions and driving profiles.

The AEC-Q200 automotive standard

Chrysler, Ford, and General Motors established the Automotive Electronics Council (AEC) in the 1990’s to create a common quality system and unify part qualification standards for automotive applications. The AEC-Q200 standard covers the stress test qualification for passive components. The earlier Rev D of AEC-Q200, which has been active since June 2010, covered components such as resistors, capacitors, transformers, resonators, crystals, resettable fuses, thermistors, and varistors. This standard covered two main stress categories for the passive components:

- Environmental stress: This includes temperature cycling, humidity bias, high temperature storage, and high temperature operating life tests.

- Physical stress: This includes vibration, mechanical shock, solderability and resistance to soldering heat, flammability, terminal strength, and resistance to solvents.

The Rev E update to AEC-Q200, released in March 2023, adds the reliability requirements for fuses. As shown in Figure 1, Rev E includes a comprehensive list of stress tests that encompass both the environmental and physical stress factors mentioned above.

Figure 1: A representation of the AEC-Q200 Rev E stress tests specified for fuses. (Image source: Littelfuse)

Figure 1: A representation of the AEC-Q200 Rev E stress tests specified for fuses. (Image source: Littelfuse)

As shown in Figure 1, the AEC-Q200 Rev E stress conditions are stricter than typical non-automotive tests. Some key tests are now added, such as the operational 1,000 hours life test at the maximum specified operating temperature. The test methodology for fuses requires pre-stress and post-stress resistance measurements, along with current carrying capacity and overload tests done post-stress. The goal of AEC-Q200 Rev E is to provide a common standard that manufacturers can use to design and test fuses used in the automotive market.

Littelfuse AEC-Q200 Rev E qualified fuses

Littelfuse has a long history in automotive fuse development and production. They first introduced automotive fuses in the 1930s, and their ATO® fast-acting blade fuses are considered the global standard. Littelfuse contributed to the development of the Rev E qualification stress tests for fuses, as their internal qualification tests for automotive fuses were already aligned with AEC-Q200 Rev E.

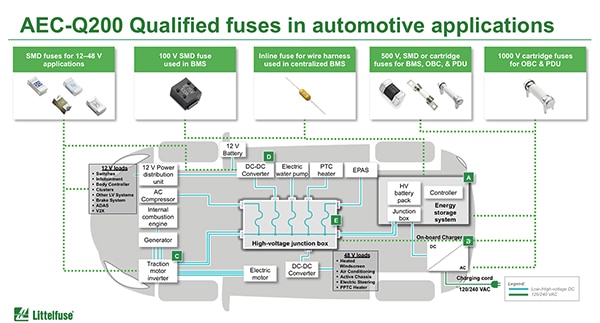

Figure 2 shows the range of fuses manufactured by Littelfuse for automotive applications. They come in a variety of body styles such as through-hole, surface mount and cartridge.

Figure 2: Showing the range of Littelfuse AEC-Q200 qualified fuses for automotive applications. (Image source: Littelfuse)

Figure 2: Showing the range of Littelfuse AEC-Q200 qualified fuses for automotive applications. (Image source: Littelfuse)

Below is a list of details on some of their AEC-Q200 qualified fuses:

- The cartridge 828 series features a high voltage rating of 1,000 VDC, with an interrupt rating of 10 kA at the rated voltage. They are targeted for OBC and PDU.

- The surface-mount 885 Nano2® series has a voltage rating of up to 500 VDC, with an available interrupt rating of 1,500 A at 350 VDC. These compact fuses can be used in Li-ion battery packs, the BMS and HV DC/DC converters.

- The surface-mount thin film chip fuse series 437A features voltage ratings from 32 VDC to 125 VDC and an interrupt rating of 50 A at the rated voltage. With their small footprint and fast response time, these are ideally suited for secondary circuit protection of compact automotive electronics such as the LED headlights, the navigations system, the TFT display, etc.

- The through-hole ceramic body PICOII® 521 series is a very fast acting fuse in a space saving sub-miniature package. The voltage rating is 75 V, with an interrupt current rating of 300 A at the rated voltage. These can be used for BMS protection.

Conclusion

EVs require more electronic and electrical power conversion components and modules. Fuses play a critical safety role, not just for the electronic components, wiring, and devices they protect, but also for the personnel operating the vehicle. The inclusion of fuses in the AEC-Q200 qualification standards ensures that these vital components meet a uniform standard. Littelfuse has a range of AEC-Q200-qualified fuses that can be used in a variety of EV overcurrent protection applications.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.