Advantages of Using Continuous Flex Control Cables in Industrial Applications

Contributed By DigiKey's North American Editors

2024-02-14

Robust connectivity supported by flexible multi-conductor control cables is required to ensure reliable functioning of industrial operations like assembly plants, conveyor systems, pick and place equipment, and food and beverage processing. Selecting and specifying control cables might seem simple, but it is a complicated process with numerous application needs and industry standards to consider.

Among the industry standards are UL oil resistance levels I and II, as well as UL 1581 vertical flame test for fire resistance; the cable must provide mechanical protection as defined in UL 1277 impact and crush tests and be able to withstand over 8 million cycles of continuous flexing at operating temperatures from -40°C to +90°C. It takes a cable with finely stranded copper conductors in a specially formulated PVC jacket suited for harsh environments to satisfy these requirements. Shielded cables are available for applications where electromagnetic interference (EMI) needs to be suppressed.

This article details the advantages of high flex cables and the applications best suited for using these cables in the context of industry standards for oil resistance, flame resistance, and mechanical protection. It then reviews the types of motion experienced in industrial applications, flex cable classes and construction options, and looks at where ÖLFLEX FD 890/FD 890 CY multi-conductor cables from Lapp fit in. It closes with examples of shielded and unshielded flex cables from Lapp and reviews the use of cable glands in standard and EMI-sensitive applications.

Oil resistance

Oil is used as a lubricant or coolant in various industrial machines, and its presence can bring significant peril to the operation and life of flexible cables. Not all insulation materials used on industrial cables react the same in the presence of oil. The formulation of the material is a differentiating factor in how they react. A critical factor in insulation materials is the presence of plasticizers that support flexibility and provide fatigue resistance.

Oil will be absorbed depending on the insulation material, or the plasticizer will leach out. In either case, tensile properties of the insulation, like flexibility, can be significantly degraded. The process is as follows (Figure 1):

- First, when oils contact polyvinyl chloride (PVC) or polyolefin insulation compounds, they interact with the plasticizers.

- If the insulating material is a polyolefin, the oil will be absorbed, causing swelling and weakening the insulation.

- If the insulating material is PVC, the oil can cause the plasticizer to leach out and cause hardening of the insulation.

Figure 1: When oil contacts cable insulation (left), it can cause polyolefins to swell and weaken (center), and it can cause PVC to lose some plasticizer material, hardening the cable (right). (Image source: Lapp)

Figure 1: When oil contacts cable insulation (left), it can cause polyolefins to swell and weaken (center), and it can cause PVC to lose some plasticizer material, hardening the cable (right). (Image source: Lapp)

Cables used in continuous flex applications like Lapp’s ÖLFLEX FD 890/FD 890 CY are required to meet two levels of UL oil resistance testing:

- Level I places the cable in oil for four days at 100°C. The cable must retain 50% of its unaged tensile strength and 50% of its unaged elongation capability.

- Level II places the cable in oil for 60 days at 75°C. The cable must retain 65% of its unaged tensile strength and 65% of its unaged elongation capability.

Flame resistance

Lapp defines seven levels of flame resistance, FR-00 to FR-06. FR-00 indicates a cable that ignites and burns easily. At the other end of the spectrum, FR-06 indicates cables with high flame resistance. ÖLFLEX FD 890/FD 890 CY continuous flex cables are rated FR-02 and are tested using the UL VW-1 (UL 1581) Vertical Flame Test.

In that test, a tirrill ribbon burner allows control of the air and gas flows. A specified flame is applied to the sample for 15 seconds and removed. The flame is reapplied after 15 seconds or when the sample stops flaming, whichever is longer. The test consists of five 15-second applications of the flame. To pass the test, the sample must not emit flame or glowing particles, and the surgical cotton at the base of the burner must not be ignited. IEC 60332-1 is the counterpart to UL VW-1, and the flame application time varies by cable diameter.

Mechanical protection

Requirements for mechanical protection vary widely. In some cases, cables will be required to survive accidents like getting hit by falling objects or being run over by a forklift or other vehicle. There are a variety of impact and crush tests for different levels of protection. ÖLFLEX FD 890/FD 890 CY continuous flex cables are rated MP-02 as defined in UL 1277 impact and crush tests (Table 1).

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 1: Lapp’s ÖLFLEX FD 890/FD 890 CY continuous flex cables have a mechanical protection rating of MP-02. (Table source: Lapp)

Motion type

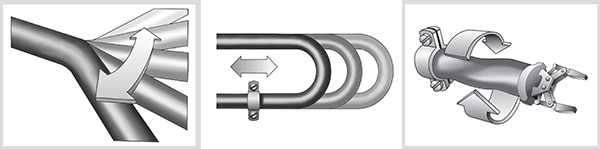

There are three basic types of motion experienced in industrial systems (Figure 2):

- Flexible cables are used in non-automated applications that experience random motion. Typical applications include machine tools and portable equipment.

- Continuous flexing cables experience constant linear motion in automated systems and experience continuous forces during bending. Applications can include horizontal and vertical c-tracks, drag chains, power chains, automated assemblies, etc. They can move back and forth at rates faster than five meters per second and experience forces greater than five times the acceleration of gravity.

- Torsion cables are subjected to bending and twisting in three dimensions. Common applications include industrial robots, pick-and-place machines, and assembly operation.

Figure 2: The three common motion types encountered in industrial systems include random flexing (left), continuous flexing (center), and torsion (right). (Image source: Lapp)

Figure 2: The three common motion types encountered in industrial systems include random flexing (left), continuous flexing (center), and torsion (right). (Image source: Lapp)

Several variables must be considered when comparing continuous flex cables, including bend radius, distance, acceleration, speed, and weight. The cable specifications need to be matched to the specific application needs. Lapp’s ÖLFLEX FD 890/FD 890 CY continuous flex cables have a continuous flex rating of CF-02 and can handle up to 8 million flexing cycles (Table 2). They have minimum bending radius ratings of 7.5 times the cable diameter for unshielded cables and ten times the cable diameter for shielded cables. The ÖLFLEX FD 890/FD 890 CY family includes a variety of cable designs with different numbers of conductors, different diameters, and different weights to match a range of application needs.

|

Table 2: Lapp’s ÖLFLEX FD 890/FD 890 CY cables are rated CF-02 for moderate continuous flexing. (Table source: Lapp)

Cable classes and construction

Industrial cables are generally specified in terms of the cross-sectional area of the wires instead of the diameter. Cross-sectional area is a valuable metric because it’s directly proportional to the strength and weight of a wire and inversely proportional to its resistance. It also relates to the maximum current carrying capacity. But it has its limitations.

Some copper has a higher resistivity than other copper. Cross-sectional area can only be used for comparisons if the wires being examined use the same grade of copper. VDE 0295 / IEC 60228 addresses those challenges by categorizing wires by resistance instead of physical dimensions.

In addition to the characteristics of individual wires, industrial cables are defined by the number and size of conductors and the number of wire strands in each conductor. VDE 0295 defines several classes of conductors based on flexibility and temperature capabilities, including:

- Class 1 are solid conductors.

- Class 2 are stranded conductors designed for fixed installation.

- Class 5 are finely stranded flexible conductors.

- Class 6 uses super-fine wires for very flexible conductors. The conductors in Lapp’s ÖLFLEX FD 890/FD 890 CY exceed the requirements of Class 6.

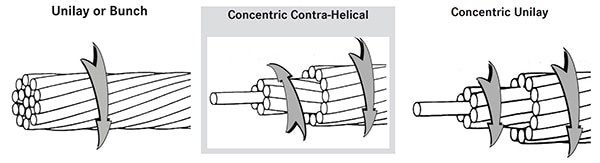

In addition to being defined by flexibility based on cable stranding, industrial cables are defined by their construction. The three most common structures of these cables are (Figure 3):

- Unilay or bunch conductors are twisted together with the same lay direction and lay length. These cables are suited for stationary applications.

- Concentric contra-helical conductors consist of well-defined layers of helically laid conductors. Each layer has a reversed lay direction and an increasing lay length. These cables are suited for continuous flex designs.

- Concentric unilay conductors are surrounded by one or more layers of helically laid conductors with the same lay direction and increasing lay length in each succeeding layer. These cables are suited for torsional and continuous flex applications.

Figure 3: Unilay or bunch cables are suited for stationary applications, concentric contra-helical cables are suited for continuous flex applications, and concentric unilay cables are suited for torsional or continuous flex applications. (Image source: Lapp)

Figure 3: Unilay or bunch cables are suited for stationary applications, concentric contra-helical cables are suited for continuous flex applications, and concentric unilay cables are suited for torsional or continuous flex applications. (Image source: Lapp)

Continuous flex cables

Lapp’s continuous flex cables are rated for 600 V and temperatures from -5°C to +90°C (-40°C to +90°C for stationary applications). ÖLFLEX FD 890 unshielded cables are available in sizes from 20 AWG to 2 AWG, and shielded cables are available in sizes from 20 AWG to 6 AWG. ÖLFLEX FD 890 CY shielded cables have an overall tinned copper braid that provides 85% coverage and is recommended when EMI suppression is needed. (Figure 4).

Figure 4: Lapp offers ÖLFLEX FD 890 unshielded continuous flex cables (top) and shielded ÖLFLEX FD 890 CY continuous flex cables (bottom). (Image source: Lapp)

Figure 4: Lapp offers ÖLFLEX FD 890 unshielded continuous flex cables (top) and shielded ÖLFLEX FD 890 CY continuous flex cables (bottom). (Image source: Lapp)

Examples of unshielded ÖLFLEX FD 890 cables include:

- 8920034, a three-conductor 20 AWG cable with an outer diameter of 6.7 mm, a copper weight of 10 pounds per thousand feet (lbs/mft), and an overall weight of about 43 lbs/mft

- 8920044, a four-conductor 20 AWG cable with an outer diameter of 7.4 mm, a copper weight of 16 lbs/mft, and an overall weight of about 53 lbs/mft

Examples of shielded ÖLFLEX FD 890 CY cables include:

- 8918034S, a three-conductor 18 AWG cable with an outer diameter of 9.5 mm, a copper weight of 40 lbs/mft, and an overall weight of about 91 lbs/mft

- 8914044S, a four-conductor 14 AWG cable with an outer diameter of 14.0 mm, a copper weight of 103 lbs/mft, and an overall weight of about 181 lbs/mft

- 8912044S, a four-conductor 12 AWG cable with an outer diameter of 16.5 mm, a copper weight of 160 lbs/mft, and an overall weight of about 302 lbs/mft

Cable glands

Cable glands are used for inserting cables into housings. They securely seal the cable and housing and provide strain relief for the cable. They also protect the housing inside from dust, moisture, and other contaminants and ensure a robust and reliable assembly. Lapp cable glands are designed and tested in accordance with DIN EN 62444. Examples of the cable glands offered by Lapp include the following (Figure 5):

- SKINTOP MS-SC brass cable glands with low-resistance screen contact and highly conductive, flexible EMC contact, like the 53112920

- SKINTOP SL/SLR polyamide cable glands like the 53015200 — durable, liquid-tight, easy-to-assemble strain relief cable glands when EMI control is not needed

Figure 5: Lapp offers brass cable glands for EMI control in addition to environmental sealing and strain relief (left and center) and polyamide cable glands (right) for applications that don’t require EMI control. (Image source: Lapp)

Figure 5: Lapp offers brass cable glands for EMI control in addition to environmental sealing and strain relief (left and center) and polyamide cable glands (right) for applications that don’t require EMI control. (Image source: Lapp)

Summary

Continuous flex cables support industrial systems like assembly operations, conveyors, pick and place equipment, and food and beverage processing. Lapp’s ÖLFLEX FD 890/FD 890 CY cables meet or exceed industry requirements for oil and flame resistance and mechanical protection and are rated for up to 8 million flexing cycles. They are available in a wide range of sizes, with and without shielding, and can be used together with the company’s cable glands to provide environmentally rugged solutions.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.