Active Cooling Solutions Extend High-Brightness LED Performance

2017-07-06

LED components and their drive electronics create a considerable amount of heat that must be dissipated to maintain optimum light output and maximize an LED’s operating life. While passive cooling using heatsinks is sufficient for typical LED applications, designers of high-brightness, high-power LED fixtures should consider active cooling.

Active, forced-air cooling does add a higher level of complexity to a fixture, but the advantages with regard to LED fixture longevity and performance, greatly outweigh such concerns.

This article will discuss the relationship between heat and LED performance. It will then introduce two forced-air cooling modules: one using a fan, the other a form of synthetic jet. Finally, an example of forced-air LED cooling in an automotive application will be discussed.

How heat affects LED performance

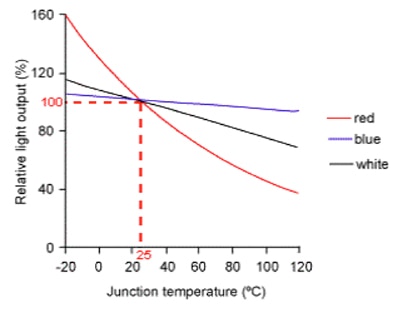

There are three main reasons to keep LEDs as cool as possible. The first has to do with the radiant power of an LED, which varies as a function of its junction temperature. Higher ambient temperature leads to higher junction temperatures. When the junction temperature increases, both the forward voltage and the lumen output of the LED decrease (Figure 1).

Figure 1: Relative light output of red, blue, and phosphor-converted white LEDs as a function of junction temperature. (Image source: Rensselaer Polytechnic Institute; data based on Lumileds LEDs and normalized to 100% at a junction temperature of 25°C).

Secondly, operating an LED over its maximum rated junction temperature can trigger a variety of stress mechanisms that considerably shorten the life of the LED. Thirdly, high junction temperatures reduce the LED’s color rendering index (CRI). The CRI is a technical measurement of how “true” the color is, based on an objective industry standard.

There are of course other benefits to be had from good thermal management. For example, effective heat dissipation also can reduce the total cost of an LED lighting system by minimizing the frequency of replacement. Good thermal management also allows fixtures to operate at higher power levels, reducing the number of LEDs that must be used to achieve a specific brightness.

Passive versus active cooling

In most situations, designers have a choice between passive or active cooling. Passive cooling uses natural air conduction and convection, generally supplemented by a heatsink to accelerate both. Heat sinks can solve thermal management problems for low lumen LED lamps. However, a heat sink alone will not cool a 75 W or 100 W equivalent LED lamp. Even if a heatsink is designed for this application, designers may find it too large, costly, and mechanically unwieldy.

To design effectively for high lumen applications, an active cooling system may be required to disperse the heat produced by LED components and drive electronics. Along with a heatsink, active cooling includes a subsystem, most often in the form of a fan, to force air over the heatsink.

A benefit of active cooling is that the heat sinks can be up to two-thirds smaller and lighter. This reduces the cost of the heatsink, as well as the size of the overall system. It also makes retrofitting more viable.

Ideal candidate applications for active cooling are chip-on-board (COB) LEDs, comprising multiple LEDs mounted on one pc board. The LEDs used in a COB are chips, and are not traditionally packaged. As a result, they can be mounted so they take up less space and provide greater accessibility for forced-air, convection-cooled heatsink and fan assemblies. When used with a COB device, an active cooling fan can effectively lower the heat temperature to 90˚F/36˚C, well below the 120˚C operating threshold of typical COB devices.

Forced-air module choice considerations

Fans designed to cool LEDs must consume minimal energy, fit into a small form factor, and have an expected life at least matching that of the light source itself (modern fan mechanisms offer a service life of hundreds of thousands of hours). Fans force air into the system, effectively lowering ambient temperature by pushing air across the heatsink for more efficient cooling. An axial fan is common, where air enters and leaves in the same axial direction.

Manufacturers typically characterize fans using a performance graph that plots airflow against static pressure, measured in either inches or millimeters of water. The air volume in these fans is relatively high and the air pressure is relatively low.

Active cooling solutions are also efficient, with many consuming as little as 0.5 watt of power. The efficiency of the fan blades varies as a function of aerodynamic loading. The peak efficiency of an axial fan typically occurs at a pressure point that is about one third of its maximum pressure. To calculate fan efficiency in terms of the ratio of input and output power, the following formula derivation can be used:

Fan efficiency = POUT/PIN

Fan input power (PIN) = PIN (Watts) = V x I

Fan output power (POUT) or airpower using Metric units = POUT (Watts) = Air pressure (in m3/sec) x Air flow (Pascals)

Using standard units the formula becomes:

POUT (Watts) = (Air pressure (in inch H2O) x Air flow (cfm))/8.5

(Formula source: NMB Technologies)

Forced-air options

Let’s now look at fans developed to keep LED junction temperatures at optimum levels. Sunon’s LED Cooling Module LA004-024A83DY is up to four times more effective than passive cooling (Figure 2). The fan uses patented DR MagLev (magnetic levitation) motors that eliminate vibration and wobble associated with typical fan motors. MagLev technology features zero friction with no contact between the shaft and bearing. Sunon’s fan design also meets the U.S. Energy Star noise regulation MR16, where the noise level measured at 12 inches is not allowed to exceed 24 dBA. Weighing 194 grams, the fan runs at 2200 rpm (+/- 10 %), has overall dimensions of just 86 x 45.4 mm, and consumes just 0.26 watts.

Figure 2: Sunon’s MagLev fan consumes only 0.26 W and runs at a quiet 17 dBA. (Image source: Sunon Fans)

All major items in Sunon’s MagLev products are made of plastic for optimal insulation resistance and electrostatic discharge (ESD) performance. Flexible enough to fit into a small form factor, the fans have an expected life of typically 50,000 hours. Their mean time to failure (MTTF) is 70,000 hours at 60˚C and 65% relative humidity.

Taking another approach to active cooling, but also designed specifically for LED modules and arrays, Aavid Thermalloy’s SynJet Cooling products use oscillating diaphragms to create a constant flow of air over the heatsink’s fins. These fanless air movers have a flexible diaphragm that “breathes.” It draws air in slowly and then expels it rapidly over the fins of a heatsink to produce highly efficient convection cooling.

In operation, the use of electromagnet actuators creates the driving force for oscillating the membrane. As the membrane oscillates within the cavity, synthetic jets (hence the name) are created at the nozzles positioned around the cavity. These rapid-fire pulses of turbulent air (typically 30 to 200 pulses per second) increase the amount of heat transferred away from the heat source with less air, enabling 75 W and 100 W LED incandescent replacements.

The SynJet Cooler model SPARS-CM012-002, for example, is designed to cool downlights, spotlights and tracklights, pendants, and PAR 30 lamps (or smaller). It has a maximum thermal wattage figure of 32 W, a diameter of 75 mm, and operates off of 12 volts DC with a choice of Level Select or PWM control. Its acoustic signature is as low as 18 dBA.

Cooling automotive LED headlamps

Cars with LED headlights are increasingly popular as the technology continues to trickle down from luxury models to mainstream vehicles. Requirements stipulate that 750 lumens of illumination per lamp is required for headlamps, so several LEDs with high output are needed to meet this standard.

The high luminance generated on a very small surface, subjects the chips to high local heat stress, and the LED junction temperature can far exceed its maximum value of 125˚C. Even in an energy saving LED headlight housing with several LED chips, the amount of heat to be dissipated quickly adds up to a few watts. Unless waste heat from the module is dissipated, a possible service life of 100,000 hours (11.4 years) for a chip in a well-cooled environment can quickly become 15,000 to 30,000 hours.

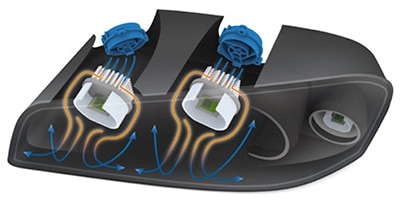

Modern LED headlamps are legally required to be delivered only as self-contained units. If even one LED fails, the entire headlight must be replaced, as there is no allowance for component replacement. As a result, the whole cooling system must be placed inside the headlamp enclosure (Figure 3). This reduces heat dissipation by convection, and due to the space limitation inside the headlamp, the size of the heatsink is restricted.

Figure 3: Because LED headlamps must be self-contained units, the entire cooling system has to be placed inside the headlamp enclosure. (Image source: ebm-papst).

There are also various climatic factors that designers need consider, including humidity, salt content, and any airborne particles. A fan built into a headlamp can apply air precisely to the areas where heat must be dissipated, or where air is otherwise required.

An example of the latter is when air moisture gathers in a non-hermetically sealed headlight housing, condensing upon the reflector and the lens. Due to the low levels of waste heat compared to traditional halogen lamps, this moisture only evaporates if air is conveyed into the housing, a task assumed by the fan, alongside its main cooling function.

Therefore, for automotive headlamp applications, ruggedly designed fans that can withstand vibration, shock, and temperature extremes in a closed environment are required. The typical operating temperature range requirement is between -40˚ and +120°C.

The engineers at ebm-papst have taken on this challenge and have developed the DC axial model 622M. The fan is compact and robust, and is specially adapted to the demands of LED headlight technology. It weighs 0.085 kg, measures 60 x 60 x 25 mm, runs at 4550 RPM, and has a service life of 77,500 hours at 40°C, and 30,000 hours at maximum temperature.

In a car, like in most other lighting systems, the cooling fan must minimize noise levels. Bearing this in mind, the designers at ebm-papst put the model 622M in an enclosed acoustic isolation ring, bringing the net acoustic noise to less than 7 dB. By comparison, background noise in a quiet office is usually about 40 dB, moderate rainfall ranks at about 50 dB, and humans cannot generally hear sounds below 12 dB.

Conclusion

Forced-air cooling is an effective way to manage LED thermals. For high-brightness LEDs in particular, the benefits of active cooling include a reduction in size of the light fixture, a decrease in overall cost, an increase in light output, and longer LED lifetime.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.