A Comparison of Digital PDM and I²S Interfaces in MEMS Microphones

2022-07-11

Microphones have been utilized in embedded systems for many years. However, since their inception, MEMS microphones have quickly seen their market usage continue to grow due to the ever-expanding range of voice-based applications in home, automotive, and wearables. MEMS microphones not only offer the benefits of significantly reduced footprints, low power requirements, and improved electrical noise immunity, but also greater design flexibility with a number of output options. Analog output MEMS microphones are still an option for engineers as well as digital outputs like pulse density modulation (PDM) and inter-IC sound (I²S).

This article will discuss these two digital interfaces in greater detail, outlining their unique characteristics as well as their advantages and disadvantages when it comes to system design. Which one an engineer chooses will come down to an examination of the two technologies and understanding how each protocol might be better suited for specific application conditions. Several key considerations that will be taken into account include:

- Audio quality

- Power consumption

- Bill-of-materials (BOM) costs

- Space constraints of the design

- Operational environment of the hardware

Pulse density modulation (PDM) overview

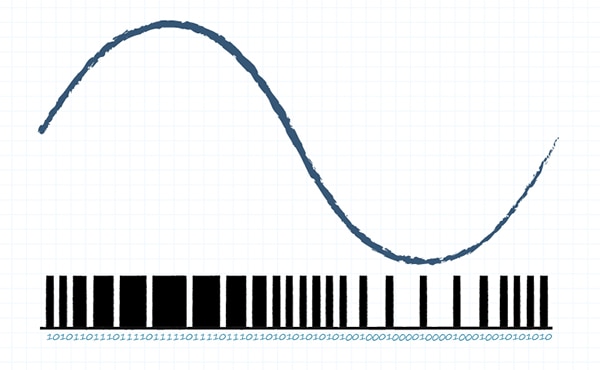

Used to convert an analog signal voltage into a single-bit pulse density modulated digital stream, PDM signals more closely resemble a longitudinal wave than the typical transverse wave seen in audio. However, they are a digital representation of an analog signal.

Figure 1: PDM protocol (Image source: Same Sky)

Figure 1: PDM protocol (Image source: Same Sky)

Figure 1 above shows how the density of the high bits increases as the analog signal amplitude increases. As a result, the digital signal remains at its low value for longer periods of time when representing the lower end of the analog signal amplitude. This creates a signal that offers many benefits of a digital signal while still being directly correlated with the analog signal. To achieve this, PDM signals require higher sampling rates, above 3 MHz, because the digital pulses must occur much more often than the oscillation of the represented analog signal.

PDM’s digital nature gives it significantly greater resiliency to electrically noisy environments compared to analog signals. It also has increased bit error tolerance when signal degradation occurs. However, the high-frequency nature of the signal leads to distance constraints due to the increased capacitance on longer transmission lines potentially causing unwanted attenuation and a resulting drop in audio quality. PDM signals also need additional processing by an external DSP or microcontroller with an appropriate codec to decimate, or downsample, the PDM signal to a lower sample rate by running it through a low-pass filter, thus making it usable for other devices. The simplicity of their concept means that PDM devices only need two signals, making them generally less expensive with lower power usage and compact footprints. These advantages come at the cost of additional circuitry to process the signal coming from the PDM device.

Inter-IC sound (I²S) overview

I²S is another popular digital interface option that originally appeared in the mid-1980s and has only recently found its way into microphones and other small devices. I²S and PDM are both dual-channel interfaces, but that is the end of their similarities. There is also often an assumed relationship or confusion when comparing I²S and I2C protocols, but their names are purely coincidental.

Figure 2: Inter-IC sound protocol (Image source: Same Sky)

Figure 2: Inter-IC sound protocol (Image source: Same Sky)

I²S is an entirely digital signal, unlike PDM, meaning that it does not require encoding or decoding. It is a three-wire serial protocol featuring a clock, data, and “word select” line, with the “word select” indicating a right or left channel where the data being transmitted is associated. While there is no universally required data transmission speed, there is a minimum speed that is dependent on the transmitted data and its precision. For example, if the audio sample rate is the industry standard of 44.1 kHz with 8 bits of precision, then a mono channel will need a clock speed of at least 352.8 kHz. This would be double that at 705.6 kHz for a stereo application. Any change in precision would also change the minimum transmission bandwidth.

Sample Frequency * Data Precision * Channel Number = Bandwidth

44,100 Hz * 8 bits * 2 channels = 705,600 Hz

A main benefit of I²S is its utilization of an internal codec through its built-in filter. Whereas PDM requires an external codec to bring its sample rate down, the audio signal’s data rate with I²S is delivered at an already acceptable level when arriving at the DSP. This eliminates extra components required for processing captured audio data within the overall design, making I²S well-suited for applications that are wholly self-contained and where energy efficient battery-powered operation is a concern. Without the need for additional external components, cost savings and space savings in compact designs, such as wearables, can also be key factors.

When looking at an overall system design, it is important to note if DSP capabilities are already in place. If so, a PDM device that can utilize the design’s built-in DSP capabilities might be a better choice over I²S that will ultimately consume more power and resources with its three signal lines.

PDM vs. I²S

PDM offers an appealing option for applications where audio quality is a priority due to its better bit error tolerance and noise immunity. On the other hand, I²S is a solid choice where space constraints or BOM costs are concerns due to its ease of installation, smaller footprint, and no need for external components for processing. I²S can also provide greater signal quality over longer distances, making it a better choice over PDM when microphone and processing circuitry are not as close to each other on the PCB. With that being said, I²S was not designed specifically for transmission over cables or other transmission devices, so this cannot be taken to an extreme as many devices will not have proper impedance matching. At the end of the day, additional research into the demands of the application, available components, and expected data rates will be needed to make any final determinations.

Summary

MEMS microphones continue to find more uses in a range of electronic devices and the selection of an appropriate interface, whether analog or digital, is crucial to achieve the best results in an end application. Same Sky has an extensive portfolio of MEMS microphones that allow a diverse array of audio system requirements to be addressed. In addition to analog interface units, various PDM digital interface microphones are readily available.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.