New Battery Charging Solutions for Li-ion Cells

Contributed By Electronic Products

2013-12-10

Over the years, demand for efficient, light, fast-charging, safe, and cost-effective portable power has led to development of many new battery technologies, including nickel-metal hydride (NiMH), rechargeable alkaline, lithium-ion (Li-ion), and lithium-polymer (Li-poly), to name a few. Generally speaking, these new battery chemistries require more sophisticated charging and protection circuitry to maximize performance and ensure safety. Fortunately, equally advanced semiconductor devices to charge and protect them have also been developed.

This article explores the virtues and limitations of the newer battery technologies. It also investigates and reports on new charging solutions for Li-ion batteries from semiconductor suppliers like Maxim Integrated, Linear Technology, and Texas Instruments.

Battery technologies

In the portable electronic equipment space, several new rechargeable battery chemistries have emerged in recent years to compete with the long-favored nickel cadmium (NiCd) technology, which continues to be attractive in applications such as power tools, where high current for short periods is needed and where the low-impedance characteristics of NiCd is desirable.

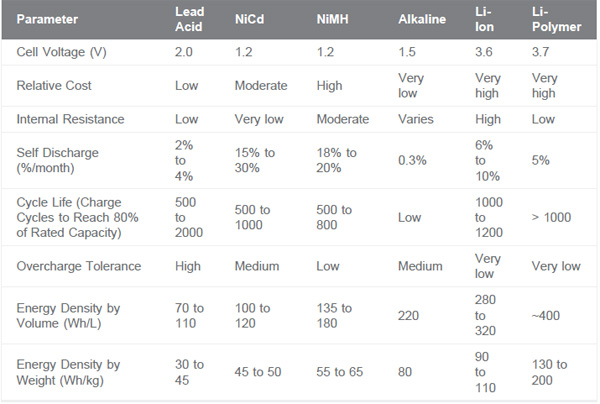

However, designers of modern portable applications such as smartphones, tablets, and digital cameras are in pursuit of batteries with higher capacity and lower discharge rates as compared to NiCd. In addition, these applications demand batteries that can charge quickly and offer low weight. Battery technologies meeting these requirements include nickel metal hydride (NiMH), lithium-ion (Li-ion) and lithium-polymer (Li-poly). While NiMH batteries feature greater capacity and faster charging, their limitation is a higher self-discharge rate, twice that of NiCd, which is relatively high to begin with (Table 1).

As described in Maxim Integrated’s application note AN676,¹ Li-ion and Li-poly have become popular in portable products because they offer much higher capacity than NiCd and NiMH batteries and have a significantly lower discharge rate. In addition, the application note shows that Li-ion batteries are also much lighter in weight. As a result, in comparison to NiMH, Li-ion batteries are rated to deliver nearly twice as much capacity per unit mass.

Li-ion batteries, however, also have several of their own limitations. Maxim points out that they are highly sensitive to overcharging and undercharging. While excessive voltage can cause permanent damage to the battery, repeated discharges to sufficiently low voltage can cause loss of capacity. Therefore, to protect the battery, the charging solution must limit the battery’s current and voltage when discharging as well as charging.

Accordingly, Li-ion battery packs normally include some form of undervoltage- and overvoltage-protection circuitry, as well as a fuse to prevent exposure to excessive current. Furthermore, Maxim’s engineers suggest that such packs also include a switch that open circuits the battery when high pressure causes it to vent.

What is more, unlike NiCd and NiMH batteries, which require a current source for charging, Li-ion batteries must be charged with a combination of current-and-voltage source. To achieve the maximum charge without damage, most Li-ion chargers maintain a 1 percent tolerance on the output voltage. Tighter tolerance is generally not recommended, as it is difficult and increases the cost. In general, the slight gain in capacity is not worth the trouble.

Single-cell Li-ion chargers

For cellphones and other similar devices, the preferred battery-charging method involves the use of a separate unit called a "cradle charger." into which you place the device or the battery pack. According to Maxim, a linear, single-cell Li-ion or Li-poly charger is suitable for use in a cradle. Since the battery pack or the charger unit is separate, its generated heat is less of a concern as it is not integrated into the device. In this case, the linear regulator drops the difference voltage (between the DC power source and the battery) across a pass transistor operating in its linear region. Because the charger is confined to a small space, airflow is recommended to prevent overheating due to power dissipation.

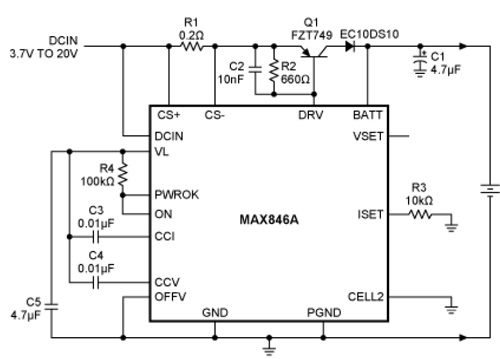

Maxim’s linear single-cell Li-ion charger is designated MAX846A. Its 0.5 percent-accurate reference allows safe charging of Li-ion cells that require tight voltage accuracy. The voltage- and current-regulation loops used to control a low-cost external PNP transistor (or P-channel MOSFET) are independent of each other. As shown in Figure 1, the external power transistor FZT749 from Fairchild Semiconductor drops the source voltage down to the battery voltage and accounts for most of the circuit's power dissipation. The result is a more stable internal reference, yielding a more stable battery-voltage limit.

In this circuit, R1 and R3 determine the output current. R1 senses the charging current, and R3 sets the level at which the current is regulated. Current out of the ISET terminal is equal to 1/1000 of the voltage between CS+ and CS-. The current regulator controls the ISET voltage at 2 V. Consequently, the current limit [2,000/(R3 *R1)] is 1 A. As described in the Maxim app note, control loops for the voltage and current limits have separate compensation points (CCV and CCI), which simplifies the task of stabilizing these limits. The ISET and VSET terminals allow for adjustment of the current and voltage limits.

Texas Instruments is another supplier offering linear chargers for space-limited portable applications. TI’s highly-integrated bq24040 series of charger ICs are intended for single Li-ion and Li-poly cells. Handling high input voltage range, the chargers operate from either a USB port or a low-cost AC adapter. According to TI, the bq2404x devices charge the battery in three phases: conditioning, constant current and constant voltage. In all charge phases, an internal control loop monitors the IC junction temperature and reduces the charge current if an internal temperature threshold is exceeded.

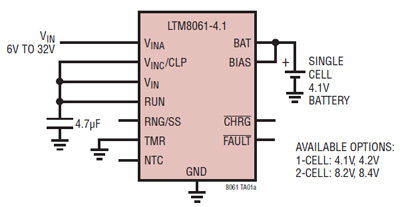

Similarly, Linear Technology’s standalone Li-ion battery charger LTM8061 is optimized for one- and two-cell Li-ion and Li-poly packs with fixed float voltage options of 4.1, 4.2, 8.2, and 8.4 V. It provides a constant-current/constant-voltage charge characteristic, with maximum charge current up to 2 A. The µModule (micromodule) battery charger’s datasheet points out that it is a complete system-in-package (SiP) charging solution with integrated DC/DC controller, power transistors, input and output capacitors, compensation components, and inductor within a compact, surface-mount LGA package. As a result, the LTM8061-based, single-cell Li-ion charger uses a minimum number of external components (Figure 2).

Other entrants in this race to provide integrated charger ICs for efficiently charging single-cell Li-ion and Li-poly packs include Fairchild Semiconductor, Intersil, and STMicroelectronics.

Charging two or more cells

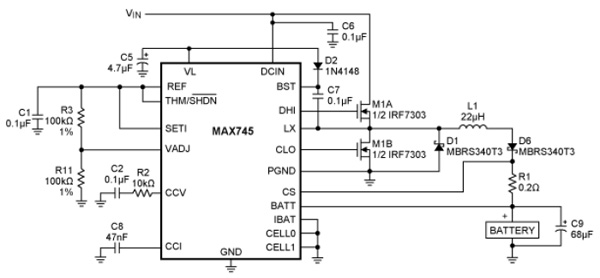

A similar circuit for charging two Li-ion cells in series is illustrated in Figure 3. It uses the Maxim MAX745, which is a switch-mode Li-ion battery charger offering 90 percent efficiency. Incorporating on-chip all functions necessary for charging Li-ion battery packs, MAX745 provides a regulated charging current of up to 4 A without getting hot, and a regulated voltage with only ±0.75 percent total error at the battery terminals. It uses low-cost 1 percent resistors to set the output voltage, and a low-cost N-channel MOSFET as the power switch. The voltage set point and charging current are regulated using two loops that work together to transition smoothly between voltage and current regulation. The per-cell battery voltage regulation limit is set between 4 and 4.4 V using standard 1 percent resistors.

Integrated ICs for charging two Li-ion cells in series are also available from suppliers like Texas Instruments and Linear Technology.

While many options are available for charging single- or multiple-cell Li-ion batteries, the designer must first examine requirements such as input voltage, charging current, charging methodology, protection capability, USB compliance, cost, and other key features before selecting a battery charger IC for the application.

For more information on the products discussed in this article, use the links provided to access product pages on the DigiKey website.

Reference

- Application Note 676, “New Developments in Battery Chargers,” November 2011, Maxim Integrated

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.