Enabling Smart-Grid Communications in Rural Regions

Contributed By Electronic Products

2015-09-02

In the smart grid, a reliable communications framework is essential for exchanging data needed to optimize power usage and cost efficiency. In rural locations, where the combination of low population density, distance, and terrain often limit other communications methods, power line communications (PLC) solutions offer a convenient vehicle for data communications. For engineers looking to implement communications in smart meters or grid-tied energy harvesting systems, PLC designs can take advantage of available devices from manufacturers including Atmel, Cypress Semiconductor, STMicroelectronics, and Texas Instruments.

In rural areas, the power line is often the best option for ensuring reliable, cost-effective smart-grid communications. In these areas, user endpoints are typically widely dispersed geographically and alternatives such as wireless provides insufficient range, and wired links or cellular broadband are not readily available or sufficiently reliable. In contrast to these alternatives, PLC can offer a cost-effective, reliable mechanism for exchanging data between the utility and consumer smart meters.

PLC design

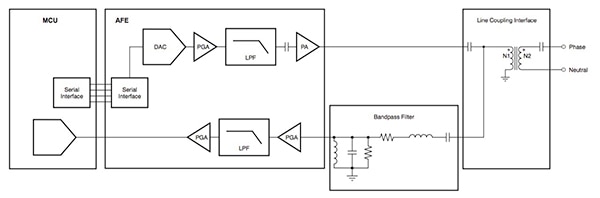

In a typical PLC modem design, an analog front end (AFE) and processor provide key functionality (Figure 1). While the AFE handles analog operations including signal transmission and reception, the processor executes the communications software stack associated with a particular PLC protocol.

Figure 1: Along with coupling, bandpass, and circuit protection, PLC modems combine an analog front end (AFE) for signal transmission and reception with an MCU for communications stack processing. (Courtesy of Texas Instruments)

To build a PLC solution, designers can combine standalone AFEs such as the Texas Instruments AFE030 and AFE031 with external MCUs such as Texas Instruments’ C2000 C28x Piccolo MCUs. With this approach, designers can scale PLC modem performance by selecting higher-performance MCUs such as the Texas Instruments Concerto multicore MCUs, which combine a C2000 C28x core and an ARM Cortex-M3. In fact, for more advanced modulation schemes such as orthogonal frequency division multiplexing (OFDM) mentioned below, higher-performance multicore processors may be required to handle more complex communications software stacks.

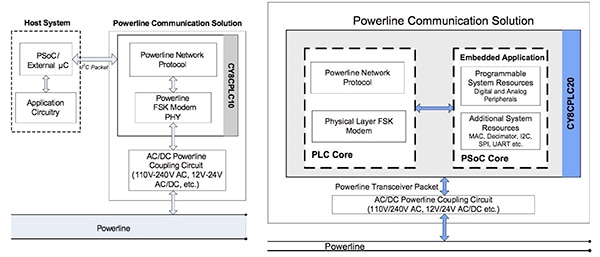

Alternatively, designers can turn to a broad array of PLC solutions that integrate larger and larger portions of the PLC communications stack on a single chip. For example, the Cypress Semiconductor CY8CPLC10 integrates a PHY layer and lower layers of the network protocol stack, while the CY8CPLC20 goes further—integrating the functionality of the CY8CPLC10 with a Cypress PSoC core able to execute more complex PLC stacks (Figure 2).

Figure 2: Manufacturers offer PLC solutions that feature increasing levels of integration. For example, the Cypress Semiconductor CY8CPLC10 integrates a PHY and network protocol stack, and the Cypress CY8CPLC20 integrates the functionality of the CY8CPLC10 along with a PSoC core for full stack processing. (Courtesy of Cypress Semiconductor)

Frequency bands

PLC operating frequencies are constrained by regional regulations to specific bands. In North America and Canada, PLC operates in the 10 kHz to 490 kHz frequency band specified by FCC (Federal Communications Commission) section 15. In Asia and Japan, it operates in the 10 kHz to 450 kHz frequency band specified by ARIB (Association of Radio Industries & Businesses). In Europe, Cenelec (European Committee for Electrotechnical Standardization) EN50065 defines a range of low-frequency bands including A-band (3 kHz to 95 kHz) and B-band (95 kHz to 125 kHz) for PLC communications, as well as C-band (125 kHz to 140 kHz) and D-band (140 kHz to 148.5 kHz) for related applications. In China, EPRI (Electric Power Research Institute) specifies a 3 kHz to 500 kHz band.

With either standalone AFEs or integrated PLC devices, manufacturers support specific frequency bands and modulation schemes in various device families. For example, the TI AFE030 and AFE031 support CENELEC EN50065 Bands A, B, C, D, while the Cypress CY8CPLC10 and CY8CPLC20 support CENELEC EN50065 and FCC Part 15 operation. Similarly, STMicroelectronics’ own series of PLC devices support specific regional frequency bands: For example, the STMicroelectronics ST7538Q and ST7540 are designed to support Cenelec EN50065, while ST’s ST7580 supports ARIB, Cenelec EN50065, and FCC Part 15.

Power-line noise

Within the allocated frequency bands, PLC systems must contend with a very noisy electrical environment. Power lines are bombarded with constantly changing noise sources including impulsive noise, noise from motors, and harmonics from power supplies and other sources as consumers turn on and off different appliances, tools, and equipment (Figure 3).

Figure 3: Low-voltage power lines are filled with noise sources that vary with consumer use, exhibiting impulsive noise (A) and wideband noise even from minor household items such a recharging stand for an electronic toothbrush (B). (Courtesy of A: Texas Instruments; B: Echelon Corporation)

Indeed, power-line noise is highly variable: A specific band can offer a clear communication channel for a period of time only to be later flooded with intermittent noise from sources in the user’s household, office, or farm. As a result, PLC receivers must often extract signals from sources exhibiting highly unfavorable signal-to-noise characteristics.

Available PLC devices including ST’s ST7538Q, ST7540, and ST7580 offer binary frequency-shift keying (B-FSK), which offers immunity to amplitude fluctuations and near-band interference. Although FSK modulation schemes offer a good solution in poor signal-to-noise environments, the wideband noise affecting most power lines require more robust communications schemes.

Noise-resistant modulation

To mitigate the effects of widely varying power-line noise sources on PLC signal transmission, PLC transceivers such as the STMicroelectronics ST7570 offers spread-frequency shift keying (S-FSK) modulation specified in IEC 61334—a standard for PLC use in utility meters. For even more demanding applications, designers can take advantage of OFDM support in PLC devices such as ST’s ST7590 and TI’s AFE030/31. OFDM’s use of multiple channels makes it particularly well suited to use in noisy applications such as power-line communications.

Two leading PLC standards—PRIME (Power line Intelligent Metering Evolution) and G3—specify OFDM to mitigate communications over noisy power lines. In fact, G3 features an adaptive method that allows compliant PLC devices to switch off communications in sub-bands with heavy noise interference. Its robust performance in noisy environments makes it well suited not only across the low-voltage lines feeding power to consumers but also in providing communications across transformers to data concentrators typically hosted on the medium-voltage lines connecting transformers to utility-power substations.

Because of the complexity of these protocols, compliant PLC modems require equally more complex PLC devices. For example, the TI AFE031 PLC IC supports PRIME and G3, but for the associated processor needed to execute the respective communications software stacks, TI recommends use of high-performance MCUs such as those in its dual-core Concerto family.

Among available integrated PLC devices, Atmel’s ATPL230A and ATPL250A are PLC modem ICs compliant with PRIME and G3, respectively. Both devices are designed to operate with high-performance MCUs such as the Atmel SAM4C MCU family. For designers looking for a single-chip solution, the Atmel SAM4CP16B dual-core ARM Cortex-M4-based PLC MCU similarly supports both PRIME and G3 in a single IC that integrates PHY and Atmel-provided PLC communications stack (Figure 4).

Figure 4: For PRIME and G3 PLC designs, engineers can build on a dual-chip set comprising Atmel’s ATPL2x PLC device and SAM4C MCU or on the SAM4CP16B—a single-chip solution offering equivalent functionality to the dual-chip set. (Courtesy of Atmel)

Development kits

To help sort through the complexity of PLC design, designers can turn to a number of development kits that combine key PLC ICs, processor, and software. The Cypress Semiconductor Corp CY3274 development kit provides a quick start for developers looking to utilize the Cypress CY8CPLC20 integrated PLC device (see Figure 2).

The STMicroelectronics STEVAL-IPP004V1 development kit provides a complete PRIME-compatible module built around the ST7590 PLC device and ST’s STM32F103 MCU—a member of the high-performance STM32 F1 ARM Cortex-M-based MCU family.

Finally, the TI TMDSPLCKIT-V3 C2000 Power Line Modem Developer’s Kit combines the AFE031 and TMS320F28069 C28x Piccolo MCU with a PLC software suite that supports S-FSK and OFDM for developing PRIME- or G3-compliant PLC solutions.

Conclusion

For rural areas, PLC can provide an effective solution for tying smart meters, household appliances, and equipment into the smart grid. For PLC designers, however, the combination of regulatory constraints, international standards, and power-line characteristics can present significant challenges. By taking advantage of available PLC ICs and MCUs, designers can more easily implement robust PLC solutions capable of operating on low-voltage lines and across transformers to medium-voltage power grids.

For more information about the parts discussed in this article, use the links provided to access product pages on the DigiKey website.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.