Controllers and PMICs Tackle Microinverter Power Conversion

Contributed By Electronic Products

2015-03-04

Microinverters help boost efficiency of solar-energy installations by managing solar-energy harvesting at the level of the individual panel rather than across the entire installation as with central inverters. In the past, however, the complex control mechanisms required to ensure maximum power output during solar-energy harvesting increased cost and limited the acceptance of microinverters. While sophisticated and cost-effective ICs and processor-based solutions handle the logic control side of microinverter designs, a variety of voltage controllers and regulators provide complementary solutions for generating power from solar panel DC output.

In typical microinverter designs, digital-logic controllers or MCUs execute maximum-power-point tracking (MPPT) algorithms designed to ensure optimum output from the panel. In this process, these logic devices monitor and adjust the power conversion path to produce AC voltage with characteristics required by the grid. Within this power-conversion path, the DC/DC converter's performance characteristics play a central role in determining the overall efficiency of power conversion and output. For engineers, an effective converter solution can utilize integrated DC/DC converters in some cases, but frequently these designs build on voltage controllers able to drive gates needed to handle higher voltage and current required for most microinverters.

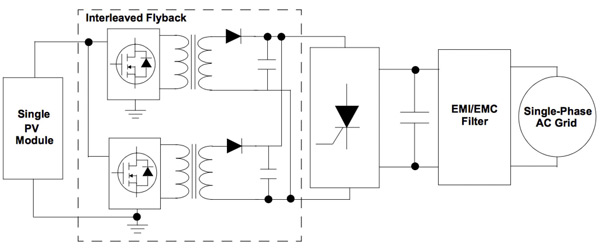

In terms of functional capability, microinverters are DC/AC power supplies driven by solar-panel output, relying on familiar voltage-converter topologies to maximize the efficiency of power conversion. For microinverter designs, forward and flyback converters remain the most commonly used topology for DC/DC conversion with silicon-controlled rectifiers (SCR) or MOSFET full bridges used to produce an AC waveform at the required grid frequency (Figure 1).

Figure 1: In a simple microinverter design, an interleaved-active-clamp flyback inverter can boost the low-voltage DC from a solar panel to deliver a high-voltage AC waveform required by the grid. (Courtesy of Microchip Technology)

As with power supply designs, microinverter designs call on a variety of design techniques to enhance efficiency and reliability. Use of an interleaved-flyback topology helps increase the life of input-bulk-electrolytic capacitors typically used in these designs by reducing the ripple-current RMS passing through them. Furthermore, the reduced output-current ripple provided with this approach results in low-output current THD. In addition, application of the active-clamp technique enables a higher maximum duty cycle, allowing use of a higher turn ratio, which can significantly reduce current stresses on the primary side and voltage stresses on the secondary side.

To ensure maximum energy output, the converter must be capable of responding to microinverter control logic designed to maintain converter voltage and current as closely as possible to the ideal characteristics generated by its MPPT algorithm. What is more, microinverters attached to the grid require the ability to disconnect themselves from the grid during power faults. In turn, these fault-protection features require power converters with overvoltage- and undervoltage-detection capabilities at a minimum.

Integrated solutions

Manufacturers provide a number of integrated solutions designed to meet microinverter requirements. Single-chip bridge controllers and DC/DC converters provide capabilities needed to implement even the most sophisticated power conversion path that maximizes power density while minimizing component count. In fact, designers can find controllers such as the Intersil ISL1801 and Texas Instruments SM72295 intended specifically for solar-panel energy harvesting.

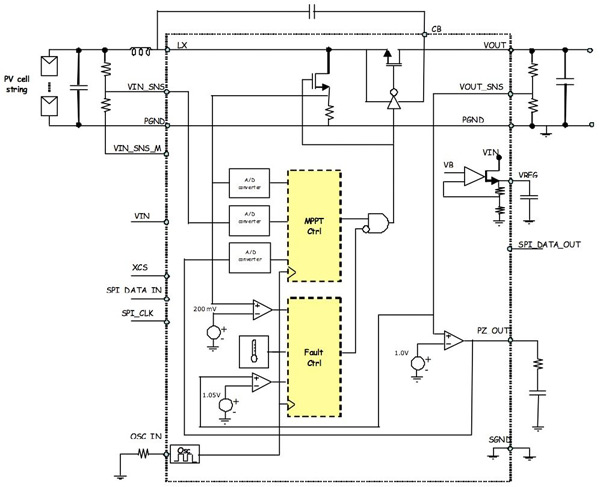

Able to support buck, boost, or buck-boost topologies, the Intersil ISL1801 integrates the required bias regulators, gate drivers, current sense amplifier, and comparators – along with a pair of switching regulators for powering other devices in the microinverter design. The Texas Instruments SM72295 similarly provides a full complement of on-chip circuits for solar-energy conversion applications. Along with transconductance amplifiers for current sensing, the SM72295 integrates four independent 3 A MOSFET gate drivers with signal conditioning, as well as filtering, power good and overvoltage-sensing functionality (Figure 2).

Figure 2: Designers can implement efficient DC/DC converters capable of handling solar-panel power output using switching controllers such as the Texas Instruments SM72295. (Courtesy of Texas Instruments)

Although not targeted specifically for solar-power conversion, a variety of switching controllers serve as attractive alternatives, each providing features able to meet specialized requirements for individual microinverter designs. For example, the Microchip Technology MCP1630V pulse-width modulator (PWM) was designed for easy integration with an MCU that might also perform MPPT and exercise overall control. With this device, designers can use MCU IO pins to control the MCP1630V’s operating characteristics including switching frequency and duty cycle, resulting in a highly flexible power system able to adapt as needed to optimize performance.

Other controllers such as the ON Semiconductor NCP1562 feature specialized capabilities such as a pair of in-phase outputs able to drive different functions within the power-conversion stage. For example, the main output can drive a forward-converter primary MOSFET, while the secondary output can drive an active-clamp-circuit MOSFET. Along with overvoltage and undervoltage detection, the NCP1562 provides additional protection features such as its “soft stop” circuitry that powers down the converter if a severe fault is detected.

While controllers address high-voltage, high-current applications, some microinverter applications can utilize integrated-power management ICs (PMICs) that provide complete DC/DC converter solutions with few additional components. For example, the Maxim Integrated MAX5033 buck converter addresses needs for power-sensitive microinverter applications, consuming only 270 µA quiescent current at no load. During heavy load operation, the MAX5033 operates at a fixed 125 kHz switching frequency and automatically switches to pulse-skipping mode to provide low-quiescent current and high efficiency at light loads.

Microinverter designers can also take advantage of other PMICs such as the STMicroelectronics SPV1020 boost converter (Figure 3) and Texas Instruments SM72485 SolarMagic buck converter designed specifically for solar-energy harvesting. Along with its integrated MPPT and fault controllers, the STMicroelectronics SPV1020 integrates power MOSFETs for active switches and synchronous rectifiers, reducing the number of external devices required to implement a DC/DC converter for solar-power conversion.

Figure 3: Designed for solar-energy harvesting, the STMicroelectronics SPV1020 DC/DC converter combines its integrated-power-conversion features with on-chip MPPT and fault controllers. (Courtesy of STMicroelectronics)

The Texas Instruments SM72485 integrates a complete set of capabilities required to implement a cost-effective buck DC/DC regulator. The SM72485 uses a control scheme that requires no loop compensation and limits current with forced off-time. Here, the device monitors output voltage and when the voltage falls below its internal reference, turns on its integrated 100 V N-channel buck switch for a fixed time determined by the line voltage and an external-programming resistor.

Conclusion

Microinverter designs bring requirements for control, power conversion, and efficiency that have limited their widespread acceptance in the past. With the availability of integrated solutions, however, designers can take advantage of a wide range of suitable devices. While specialized processors provide advanced-control functionality and MPPT capabilities required in microinverters, design of the power-conversion stage requires devices with the performance characteristics and functionality needed to deliver power to the grid safely and efficiently. By drawing on a wide choice of available integrated-switch controllers and PMICs, engineers can create highly efficient, cost-effective power-conversion stages in microinverter designs.

For more information about the parts discussed in this article, use the links provided to access product pages on the DigiKey website.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.